Published by Dranetz – BMI Case Studies

As the first thunderstorms of the season begin to roll through, it is important to safeguard your facility’s equipment against the significant damage that can be caused by the high frequency transient energy of lightning strikes. The first step is to make sure that you power monitor is up to the job and is capable of capturing these events. Unfortunately, many are not—here’s why. The term “transient” is now being defined in nearly every PQ monitoring equipment spec sheet to mean anything from a ¼ cycle drop-out to a sub-microsecond impulsive transient. According to IEEE, RMS variation are events that last longer than ½ cycle, leaving transients to be anything shorter than that. So, a typical instrument that samples the voltage at 128 times a cycle and triggers on an RMS variation will only capture the typical 1.2 x 50 microsecond lightning impulsive transient if it happens to occur during that sampling cycle. The odds of your monitor capturing such is at best, 33%.

Your odds go up significantly if your monitor has the ability to capture high frequency transients through either a 1MHz or faster sampling rate, or using high-frequency, reset-able dual peak detectors. Peak detectors incorporate high frequency circuitry into a peak-hold circuit that saves the largest magnitude value until it is reset. Provided that it is reset often, such as 128 times a cycle, it will capture that lightning-generated voltage transient and enable you to assess any impact to equipment.

Now we will evaluate the most common PQ occurrence during lightning storms and see how an effective monitor captures these events. In the following example, there were nearby direct or coupled lightning strikes to the electrical distribution wiring that feeds the facility. The facility relied on several surge suppressor strips, which contain TVSS (transient voltage surge suppressors) devices. These are components that are able to divert large amounts of energy into the ground conductor or phase-to-phase, away from the load, by radically lowering their impedance when the voltage tries to climb above a preset value.

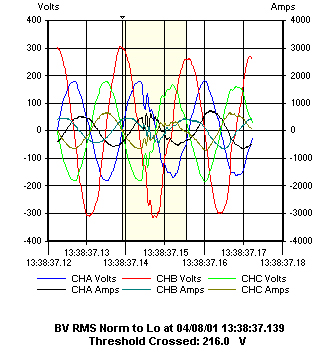

When these TVSS devices work properly, the voltage level is clamped at a safe level, often under 250V peak for a 120V AC line. Many PQ monitors are set to 500V peak or higher for transient triggering, but when the lightning strike occurs and the TVSS works, the PQ monitor will not trigger. In this case, ignorance is not bliss as the strike did cause a significant current transient, meaning that the energy had to go somewhere. Fortunately, a PQ monitor that triggers on current transients using peak detectors will enable you to capture that data and evaluate the performance of the TVSS.

But why should you care about the event if the TVSS worked and the voltage was clamped, especially if there was no obvious equipment damage? Unfortunately, the TVSS was impacted slightly and each time it takes a hit, it loses some of its capability to divert the energy. Enough times, and the TVSS may fail. Then you have no protection, and you do not even know it. By monitoring for both current and voltage transients, you can see that the lightning transient did impact the electrical system, that the TVSS devices did their job, and determine if those devices are degrading and need to be replaced before a catastrophic failure. In other words, an effective monitoring instrument can be used to schedule maintenance in advance of devastating failures, optimize your mitigation equipment and maximize electric reliability.

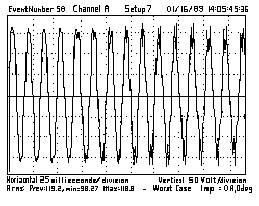

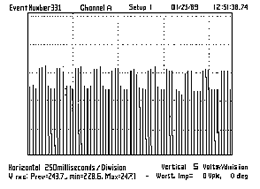

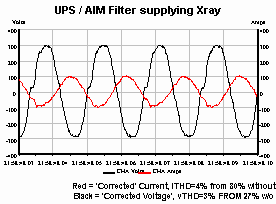

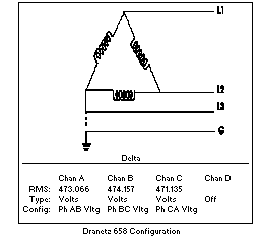

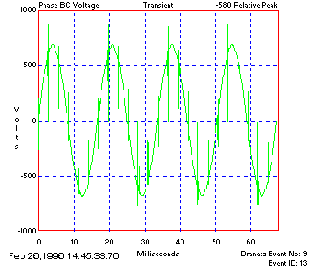

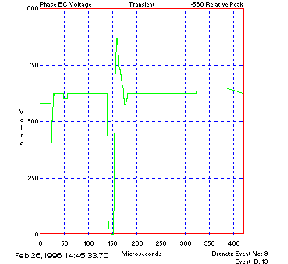

Now let’s look at the data: Voltage A and Current C are upstream, whereas Voltage B and Current D are near the load. The first two figures show the voltage and current waveforms when there is no TVSS in the circuit. Not surprising, the 1038Vpk and 92A transient appears the same at both monitoring locations. The third figure shows a zoomed in version of the transients, with the fast rise and somewhat slower decay of the classic lightning impulsive transient.

The last two figures shows what happens when the same transient is generated into surge suppressor strip rated at 400V. Upstream from the device, the voltage is clamped to just over 400V but the current rises to 360A. Downstream, the voltage is under 400V and the current a mere 5A. Clearly, the device did its job, this time. But if the monitor had been set to 500Vpk trigger, the transient into the TVSS circuit would not have been captured without current transient triggering. With a 250Vpk TVSS, the probability of missing the event on a voltage-triggered monitor is greater, even with high-frequency transient voltage detection This data underscores the need for a monitoring instrument that can truly capture high-speed current transients before they capture your equipment.