Published by Dranetz Technologies, Inc., Technical Documents – Application Note

SUMMARY

Controlled environment agriculture (CEA) relies on advanced technologies such as climate control systems, artificial lighting, and hydroponic or aeroponic growing systems. These systems, in turn, require stable, clean power. This Application Note outlines how a New Jersey-based indoor farming facility addressed persistent HVAC and VFD failures by installing a Camille Bauer PQ5000 permanent power quality and energy meter along with Dranetz master monitoring station. The meter and station setup provided insight into utility feed conditions, helped diagnose internal power events, and offered actionable data to prevent crop loss.

Indoor Cultivation Requires Reliable Power

CEA facilities typically aren’t simple greenhouses. Rather, they’re high-density industrial spaces that replicate ideal outdoor conditions, down to temperature, humidity, airflow, and CO₂ levels. And they must do it 24/7. Such a facility includes:

● High-intensity lighting systems

● HVAC systems tailored for tight humidity and temperature control

● Dehumidifiers and reheat coils

● Irrigation pumps

● CO₂ emitters

● Fans for air movement

● Automated environmental monitoring and controls

The Electrical Load Behind the CEA Facility

Keeping a CEA facility running often requires electrical engineering expertise as much as horticultural smarts. Lighting, HVAC, and environmental control systems often run on dedicated circuits and variable frequency drives (VFDs) to maintain efficiency. Many facilities also operate with year-round HVAC cycles, meaning cooling and dehumidification don’t stop, even in winter.

Key electrical demands include:

● Continuous operation of HVACD (Heating, Ventilation, Air Conditioning, Dehumidification) systems

● High wattage lighting (e.g., LED or HID systems)

● CO₂ delivery and sensor systems

● Centralized control systems and security monitoring

As a result, CEA facilities can be major utility customers. Energy usage can reach 16,000 kWh per day for mid-size operations.

Common Power Quality Challenges

With this level of electrical demand, it’s clear that power quality can directly impact yield, product quality, and profit margins. Even minor disturbances in power quality can disrupt operations. And that’s exactly what started happening at the New Jersey facility.

Power quality risks in CEA operations can include:

● Harmonic distortion: Caused by LED drivers and VFDs, leading to overheating and potential equipment failure.

● Voltage sag or drop: Especially during load start-up events.

● Power interruptions: Even brief outages can stress environmental control systems, leading to inconsistent grow conditions or system lockouts.

● Grid impact from load density: In regions where multiple, large energy consuming sites operate within the same utility zone, the collective demand can stress local distribution systems, causing grid instability and the potential for increased power outages.

These issues aren’t theoretical. At the NJ facility, the HVAC system and VFDs began failing unexpectedly, threatening their high-value crops. Without clean, consistent power, environmental parameters swung outside of acceptable ranges, forcing growers to discard product.

NJ Facility Overview

This New Jersey CEA facility spans 58,000 square feet and is fed by a 480V, 8000A service, split into two 4000A services. The electrical infrastructure includes:

● Two 480V pad-mount transformers for utility power

● Outdoor switchgear

● Roof-mounted HVAC units and VFDs

● Complex lighting schedules with ~12-hour cycles

● Estimated 16,000 kWh of daily consumption

The size and complexity of the load created real vulnerability to power quality issues, especially at the utility service entrance.

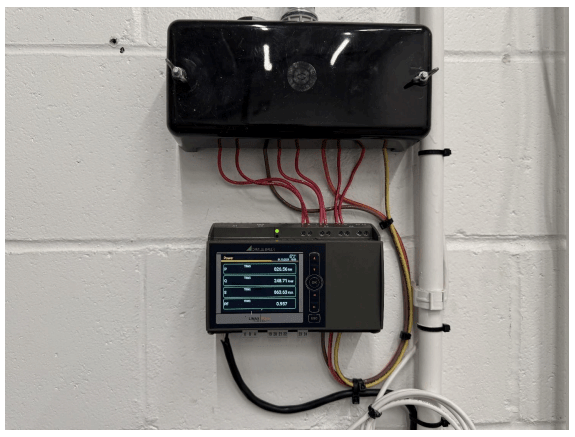

Installation of the Camille Bauer PQ5000

To understand the root cause of HVAC and VFD issues, the facility team installed a PQ5000 permanent power quality monitor on one of the two 4000A service feeds. The unit was mounted with:

● Voltage disconnects

● CT shunt assembly

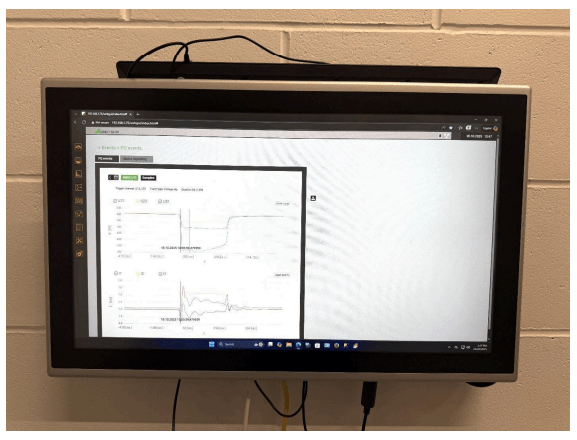

●Integration with a Dranetz Master Station for graphical user interface and remote monitoring via web interface

This setup allows facility engineers to:

● Continuously monitor utility feed conditions

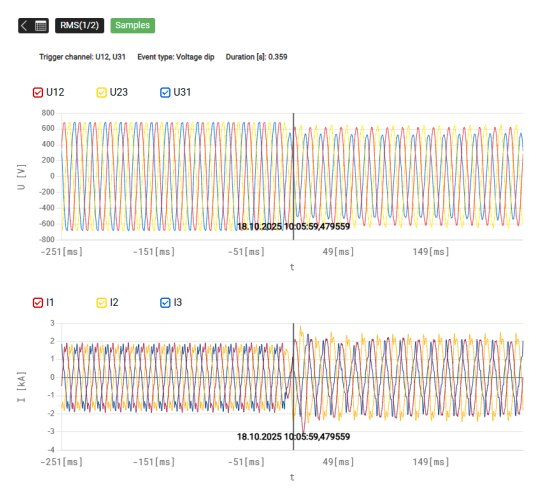

● Capture waveform and RMS data in real time

● Proactively monitoring and analyze disturbances without waiting for failure

● Profile energy use by load and time of day

In the first two weeks of operation, the system captured normal operations and RMS startup events, confirming that load initiations weren’t to blame. The facility now has a clear baseline and is prepared to identify deviations before they lead to downtime.

Why the PQ5000 Works for CEA Facilities

Here’s why PQ5000 is a strong fit for controlled environment facilities:

Continuous Monitoring

Power doesn’t fail on a schedule. The Camille Bauer PQ5000, coupled with the Dranetz Master Station, provides 24/7 data on:

● Voltage sags/swells

● Harmonics

● Frequency variations

● Energy utilization

Grid & Load Side Visibility

This setup helps separate utility-side events from internal equipment issues, a key need in determining where disturbances originate for fast resolution.

Fast, Actionable Insight

The system offers waveform capture and automated analysis. Site engineers don’t need to sift through raw data to understand what happened.

Energy Profiling

CEA facilities often operate on tight margins. The PQ5000 enables:

● Demand, kWh and other tracking

● Load pattern analysis

● Lighting schedule verification

Scalable & Future-Ready

As the NJ CEA site expands, a second PQ5000 will be added to the remaining 4000A feed. The system’s modular design and web interface support multi-site deployment and long-term scalability.

Adopting a Proactive Monitoring Approach

Power quality problems can be silent yield killers in indoor cultivation facilities. Failures in HVAC, VFDs, and other systems can damage crops before anyone notices.

By installing the PQ5000 and master monitoring station, this NJ facility moved from reacting to equipment failures to proactively monitoring the health of its electrical infrastructure. They experienced:

● Greater confidence in environmental control

● Better decision-making using power profile data

● Reduced risk of batch loss due to unknown power events

Ready to Get Ahead of Power Problems?

If you’re designing or running a CEA facility for high value crops, you will want to be as proactive as possible about PQ issues, like these NJ growers are. The Camille Bauer and Dranetz permanent PQ monitoring systems give you the insight to manage uptime and protect crop quality, and improve energy efficiency with data you can trust.

Visit dranetz.com/product/pq5000 to learn more or contact our team for help tailoring a monitoring plan to your facility.

Dranetz and Camille Bauer are GMC Instruments brands for power quality and energy management. GMC Instruments is a global leader in electrical measurement and testing technology. GMC Instruments Americas is the GMC Instruments sales and support center for the Americas for all GMC Instruments brands.

Website: Dranetz.com , Call 1-800-372-6832 (US and Canada) or +1-732-287-3680 (International)