Published by Jacek KOZYRA1, Zbigniew ŁUKASIK1, Aldona KUŚMIŃSKA-FIJAŁKOWSKA1, Piotr TAŃSKI2, Kazimierz Pulaski University of Radom, Faculty of Transport, Electrical Engineering and Computer Science (1) Baxtom Sp. z o.o, (2) ORCID: 1. 0000-0002-6660-6713, 2. 0000-0002-7403-8760, 3. 0000-0002-9466-1031

Abstract. Poor quality of electric energy is a large problem for most of the enterprises and production plants taking actions aiming at increasing energy efficiency. Many of them have already implemented the simplest means ensuring proper quality of energy that do not require large investments. Interferences of qualitative parameters of energy will be more frequent, which is caused by ageing infrastructure and introduction of energy-efficient and power electronic devices supporting production processes. New solutions applied in the industry such as drives of variable speed and LED lighting, introduce harmonics, which results in excessive heat, reduction of capacitive reactance available in supply system and additional costs. The main goal of this publication was to present the problem of interferences caused by poor quality of electric energy in the supply systems of an industrial plant. Based on measuring data collected from an analyser mounted in a selected production plants, the causes of abnormal phenomena occurring in a supply network were determined. A solution to the problem was proposed and expected effects resulting from application of devices for compensation of generated distortions were presented.

Streszczenie. Zła jakość energii elektrycznej jest dużym problemem dla większości przedsiębiorstw i zakładów produkcyjnych podejmujących działania mające na celu zwiększenie efektywności energetycznej. Wiele z nich wdrożyło już najprostsze środki zapewniające odpowiednią jakość energii, które nie wymagają dużych inwestycji. Zakłócenia parametrów jakościowych energii będą coraz częstsze, co spowodowane jest starzeniem się infrastruktury oraz wprowadzaniem energooszczędnych i energoelektronicznych urządzeń wspomagających procesy produkcyjne. Nowe rozwiązania stosowane w przemyśle, takie jak napędy o zmiennej prędkości i oświetlenie LED, wprowadzają harmoniczne, co skutkuje nadmiernym nagrzewaniem się, zmniejszeniem reaktancji pojemnościowej dostępnej w systemie zasilania i dodatkowymi kosztami. Głównym celem niniejszej publikacji było przedstawienie problemu zakłóceń spowodowanych złą jakością energii elektrycznej w systemach zasilania zakładu przemysłowego. Na podstawie danych pomiarowych zebranych z analizatora zamontowanego w wybranych zakładach produkcyjnych określono przyczyny zjawisk nietypowych występujących w sieci zasilającej. Zaproponowano rozwiązanie problemu i przedstawiono oczekiwane efekty wynikające z zastosowania urządzeń do kompensacji generowanych zniekształceń. (Analiza eliminacji zakłóceń w systemie zasilania zakładu przemysłowego).

Keywords: Distribution company, The Quality of Electricity, Higher Harmonic, Active Harmonic Filter, AHF.

Słowa kluczowe: Spółka dystrybucyjna, Jakość energii elektrycznej, Wyższe harmoniczne, Aktywny filtr harmonicznych, AHF.

Introduction

Currently supplied electric energy has become a product, characterized by many technical parameters affecting the aspects connected with reliability of power supply for selected elements of power system [1, 14]. Supply of electric energy of appropriate technical parameters results now from legal regulations and has significant impact on stability, safety and continuity of work of every industrial plant. Therefore, interest in the issues connected with quality of electric energy, methods of its measurement and improvement of its parameters has been growing for several dozen years [6].

Monitoring of the values of parameters determining the quality of electric energy has become the subject of interest of the producers, distributors and consumers [2]. Distribution companies are obliged to supply energy of specific qualitative parameters, whereas, consumers, by paying for supplied energy, feel responsible for its verification. It results from the fact that monitoring of quality of electric is significant not only due to technical and safety aspects, but it is also significant from trade point of view.

The issue of quality of electric energy is becoming increasingly important and contributes to development of technological solutions both for registering of qualitative parameters and elimination of interferences introduced to the network [3, 4, 9, 10]. Proper operation of devices requires that the values of specific features of electric energy supplied to a given receiver are within specific ranges of rated value [7, 8]. On the other hand, we have observed the growth of the number of applied receivers, which are the source of generation of distortions in the power grid, due to their non-linearity, among others, application of frequency converters [5]. At present, along with growing awareness, industrial plants invest in the solutions compensating generated distortions [16]. This fact is also caused by growing interest in the quality of energy supplied in the power grid by distribution companies because industrial plants, due to applied receiving devices, are the source of generating interferences in the network [12, 15].

The analysis presented in the publication is of research character and the main goal of this article was to present the problems connected with quality of electric energy in the supply system of the industrial plant, methods of its monitoring and improvement. Based on data collected from an analyser in a selected industrial plant, the solution to the specific problem was developed and proposed along with presenting the effects resulting from application of devices compensating generated distortions. The presented solution is an engineering example of improving current and voltage distortions, which, thanks to the reduction of generated power affecting the quality of electricity, gives measurable financial effects. The authors, thanks to the research and thorough analysis, suggest how to methodically solve the problems of deformation of power supply parameters.

The actions taken in order to improve the quality of electric energy in the energy distribution companies

From the point of view of the Distribution System Operators (DSO), reliability of energy supply is a key issue for inhabitants, enterprises and production plants. It is one of determinants of standard of living and it significantly affects economic growth of the whole country. Investment actions taken by the companies in cooperation with local governments may contribute to increasing energy safety in the communes and towns/cities. Good cooperation between local governments and energy sector allows to systematically increase indicators of reliability of energy supply and shorten power cuts. Investments in the distribution networks and cooperation while planning and expansion of power infrastructure, improving stability of power supply, give notable benefits to investors, local governments and inhabitants of the region [13, 17]. Reliability of energy supply is also the most important goal of a new model of adjustment of large energy distributors with qualitative elements, that is, a model of qualitative adjustment for distribution system operators. A model of qualitative adjustment is focused not only on increasing reliability of energy supplies to the consumers, improving safety, increasing of technical efficiency of customer service, automation of the network and improving its technical condition, but also on the aspects of the parameters of quality of energy supplied to the consumers.

The works and actions of distribution system operators aimed at monitoring and controlling of indicators of quality of electric energy have become an everyday practice, which include measurements and long-term recording [18, 19]. They are mainly forced by the complaints submitted by the consumers about the level of indicators of quality of electric energy. Collected measuring data are also of key importance for taking repairing, modernization and investment actions. The operators focus mainly on using mobile analysers, which temporarily execute measuring tasks. Operation of distribution networks is constantly monitored by the systems of constant monitoring, which are based on stationary analysers placed in key system points [20].

Another future source of data and information will be successively installed meters for remote measurement of electric energy allowing to read many parameters concerning voltage, consumed current, power and measuring harmonics and THD indicators (Total Harmonic Distortion). Additional Advanced Metering Infrastructure (AMI) will support and enable measurement and recording of indicators of quality of electric energy. In practice, above actions allow quick analysis and provide better control of receivers working in the network.

Other DSO actions aiming at improvement of quality of supplied energy taken, among others, in cooperation with the European Union based on operational programs oriented towards development of the platforms of data management from advanced measuring infrastructure, development of the system of assessment of propagation and improvement of the parameters of quality of electric energy in the distribution networks, creation of a prototype of the system supporting the process of management of WN/SN transformers based on multiparametric analysis of measuring results. These actions enable to determine optimal and significant places of measuring and monitoring of the parameters of quality of electric energy in the distribution network, estimate selected qualitative indicators and assembly of new devices and systems of on – line monitoring and assessment of quality of electric energy.

The research on the use of advanced methods of location of disturbing receivers and tools for assessment of their individual emission, including sources of harmonics and sources of voltage fluctuations are in progress. Devices and methods to improve quality for automatic reduction of the impact of disturbing receivers on the level of quality in a distribution network shall be used. The implementation of new systems is supposed to improve management of electric energy through more effective control of flow of energy, increasing reliability of energy supply and reduction of threats resulting from momentary changes of parameters of voltages and currents. The main consumers of such system will be distribution system operators and energy consumers, mainly large enterprises. Functionality of such system will be a great support while making important investment decisions aiming at improvement of quality of electric energy and reliability of energy supply.

An analysis of elimination of interferences in the supply system of the industrial plant Industrial plant supply system

A production plant, in which the research and analysis of power grid were conducted is Poultry Production and Processing Plant. The enterprise manufactures poultry products and transports them. The departments that the plant consists of:

– storage and production preparation department,

– apparatus and production devices zone,

– production department,

– sorting department,

– packing and transport department.

The poultry enterprise is supplied by 15 kV medium voltage overhead line, which includes a support structure with RUN switch. From the switch towards indoor transformer station, there is 15 kV SN cable line, which is an internal line supplying the plant. Indoor transformer station with two 630kVA transformers of 15/0,4 kV voltage ratio was built in the plant. It is 4-pole Rotoblok medium voltage switchgear along with two-section low voltage main switchgear.

In order to increase reliability of power supply, two 550 kW generators were installed in the plant, each one with an automatic transfer switching system. Power of connection of the plant to the network is 1,1 MW with installed power 1,56 MW. An important element of the production process is ensuring constant temperature during production and continuity of this process. Therefore, it is necessary to ensure high reliability of supplying the plant with electric energy. Power cuts for production devices lasting a few minutes cause losses in a technological process, and may generate big losses in mass production.

Interferences in the supply system

In 2018, new production devices with a few single-phase frequency converters controlling the production process were installed in the plant. After opening of extended part of the plant, considerable growth of temperature of a neutral conductor was observed and as a result, rebuilding and increasing diameter of neutral conductors in the department switching stations were necessary. Despite these actions, the problem of asymmetry was only partially reduced and increased temperature of neutral conductors was still observed. In order to obtain larger number of data and information about the causes of interferences in the supply system, standard measurements of the parameters of the network supplying the plant were taken.

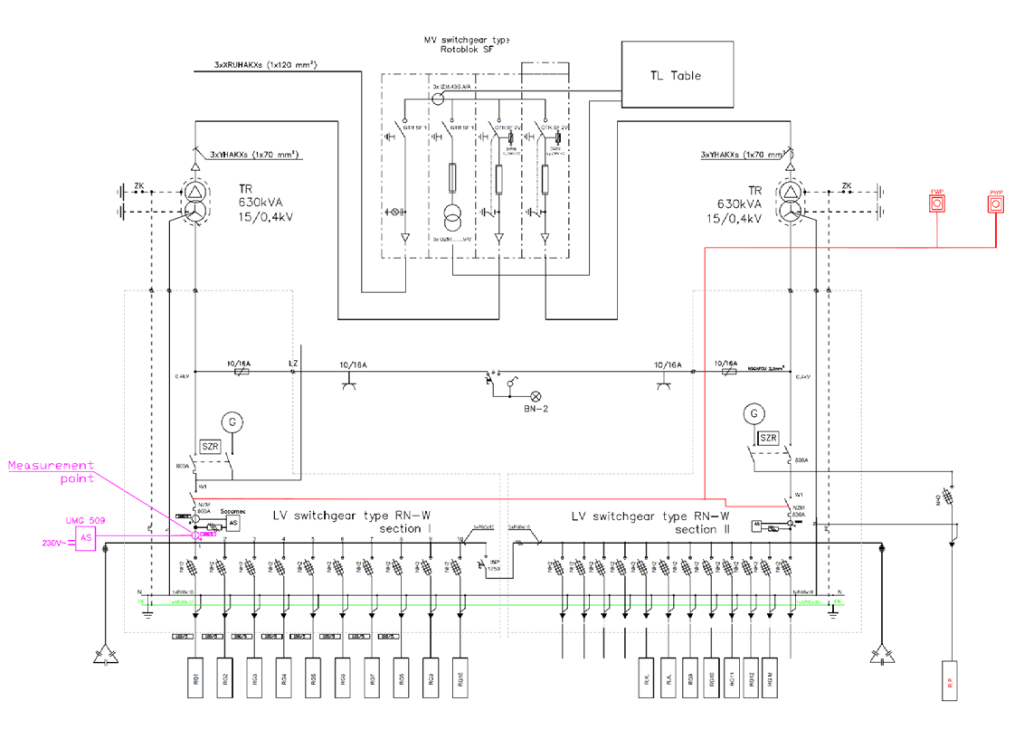

Diagnosis of interferences started from taking readings from installed UMG 509 analysers of network parameters installed in the supplying field of the main switching station of the plant. Supply system of the plant and place of taking measurements were presented on Figure 1.

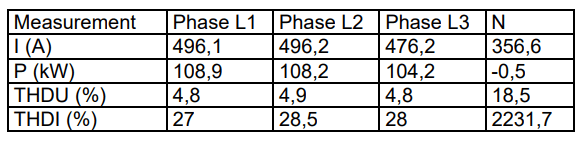

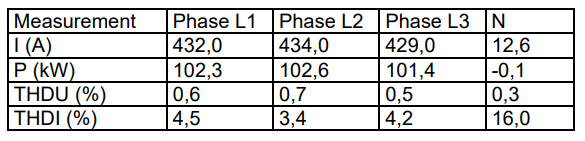

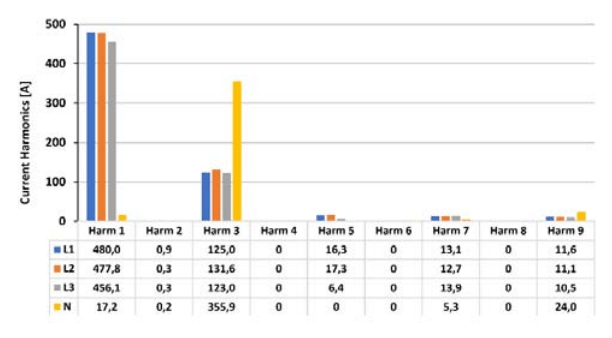

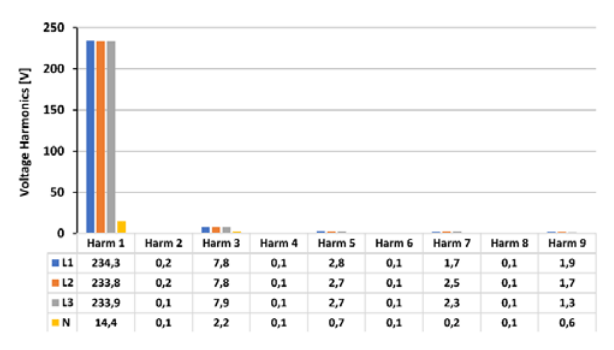

The analysers were installed for the network of asymmetrical load with current measurement in three phases. The analysers showed even loads of specific phases and substantial flow of current in a neutral conductor. Based on the measurements, it was found that supply network is characterized by the presence of high rates of total harmonic voltage and current distortion, which amount to for current: L1–27%, L2–28,5%, L3–28% and N–2231,7% and for voltages: L1–4,8%, L2– 4,9%, L3–4,8% and N–18,5%. Measurement of power in specific phases for considered electric switchgears was, on average 108,5 kW. The results of all measurements were presented in the Tables 1÷3.

Table 1. The results of measurements of current, power, THDU and THDI in the supply system

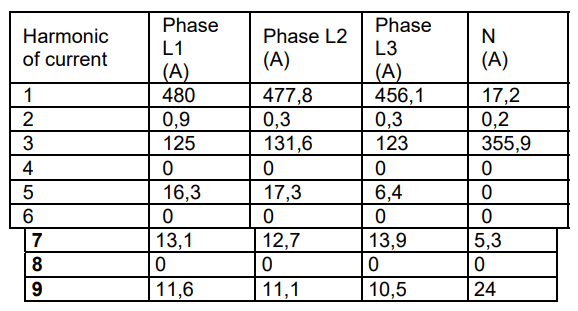

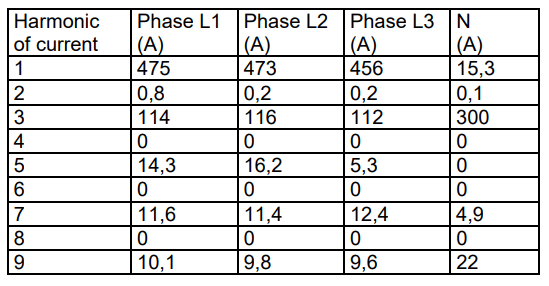

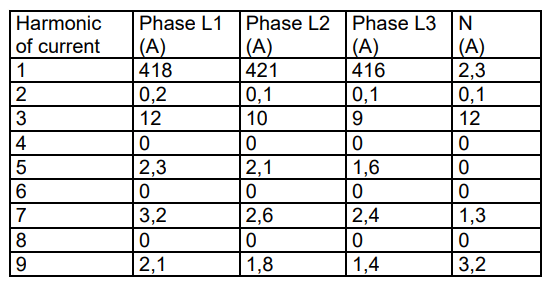

Table 2. The results of measurements of current harmonics in the supply system

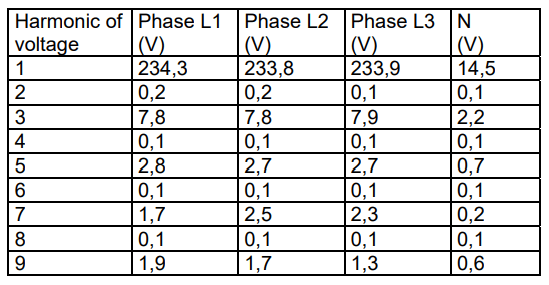

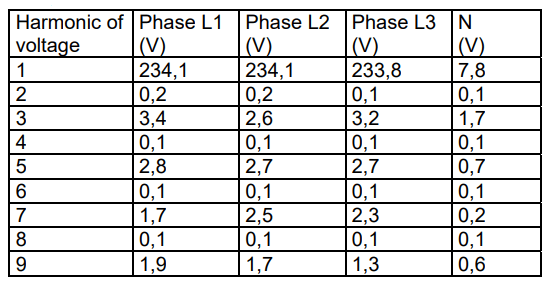

Table 3. The results of measurements of voltage harmonics in the supply system

Measuring equipment registered 9 voltage harmonics and 1, 2, 3, 5, 7 and 9 current harmonics. The highest values of current harmonics for the phases were observed in the event of basic harmonics and 3 harmonics in a neutral conductor. It must be said that 3 harmonics for specific phases also have high values (on average 127 A).

Measurements and analysis of quality of energy using UMG 509 analyser were conducted in all selected department switchgears of the plant. An analysis of conducted research and recording of measurements showed that the source of interferences are started and put into operation production devices supplied from department switchgears R1, R2, R3, R4, R5, R6, R7, R8, R9. Every switchgear supplies twelve devices with 2,2 kW single-phase frequency converter. The switchgears were adapted to supply asymmetrical circuits as four-wire supply system with a neutral conductor. Occurrence of third harmonics and their multiples was considered for asymmetrical circuits. In the examined switchgears according to the PN-EN 610000-3- 12 standard, Rsce > 350 and permissible value of current of third harmonics is 41% of rated current.

It was determined that in the event of asymmetrical load, current of third harmonics resulting from summing up currents of third harmonics coming from three phases occurs in a neutral conductor. In particularly bad situation, algebraic summing of these three phase currents occurs, which causes flow in neutral conductor current of the value of 123% of rated current. This value is many times greater than the permissible 41% of the rated current, which is defined as in the PN-EN 610000-3-12 standard. [21]

The measurements show occurrence of higher harmonics, which considerably complicates operation of the network and electric devices and causes increased power losses and problems with calculating voltage drops. Applicable regulations limit permissible values of both currents and voltages of higher harmonics in all electrical circuits, both low- and high-voltage ones.

Elimination of interferences of the supply system

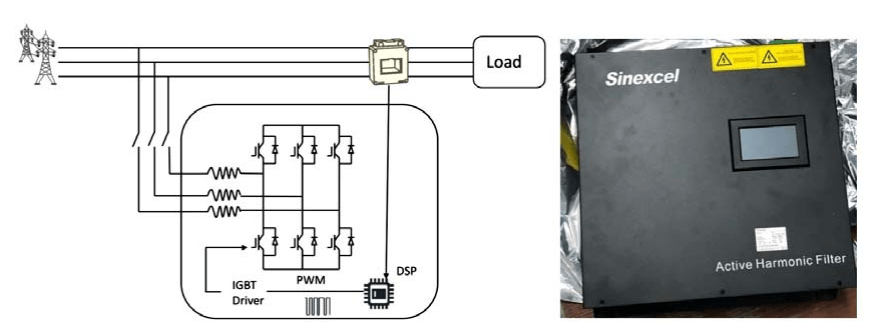

In order to eliminate interferences in the power grid of the plant, taking specificity and need of reliability of power supply into account, it was accepted that best method of elimination of interferences will be assembly of active filters. Active filters near the source of generation of interferences will be mounted in every switchgear supplying production devices. Sinexcel Active Harmonic Filters were applied to reduce higher harmonics. Filters of active harmonics reduce harmonics caused by non-linear load to the power grids [10]. It is usually installed in parallel to pollution loads. Active filter analyses harmonics of the mains electricity consumed by the loads and generates compensatory current as an opposite phase angle, neutralizing current harmonics. A set of modular Sinexcel Active Harmonic Filters is suitable for all types of applications, providing balancing of load with filtering of harmonics and stepless compensation of reactive power for leading and lagging loads. Figure 2 presents the filter applied to eliminate interferences in the modernized network.

As shown in Figure 2, Sinexcel AHF detects the load current in real time via external current transformer and extracts the harmonic content of the load current. After analyzing the data, the controller the AHF drives the internal IGBT with the PWM signals and causes the inverter to produce the reverse current of the same harmonic magnitude of the load, which is injected to the power grid to compensate for harmonic current [11].

In the production plant, interferences in the supply network have the form of:

– presence of 1st-9th order harmonics,

– high value of total harmonic current distortion,

– high value of total harmonic voltage distortion,

– increased power consumption caused by harmonics and voltage and current distortion,

– increased current flow caused by harmonics and current distortion

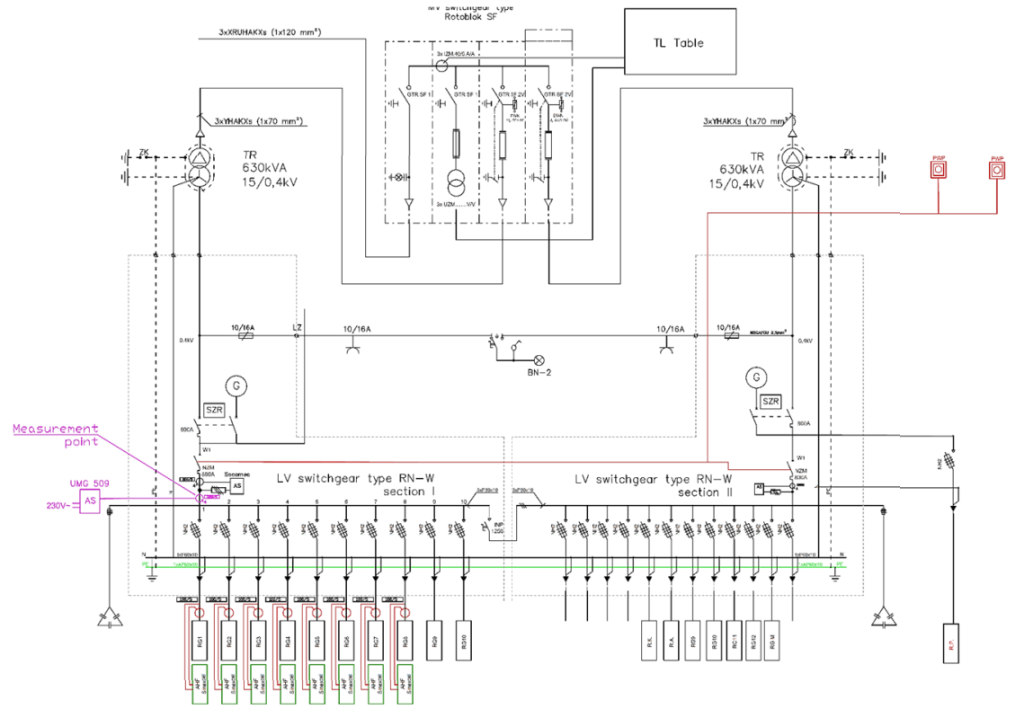

n order to eliminate interferences in the network, active filters of current and voltage harmonics are recommended. In the first stage of modifications of the network, 1 filter was installed. Then, due to the necessity of reduction of higher harmonics, the number of installed filters was increased to 8. The places of installation of AHF filters were presented on Figure 3.

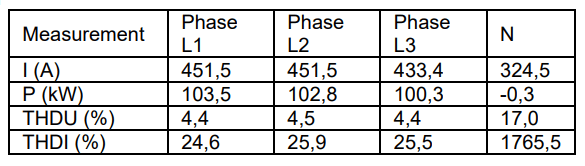

The results of measurements for 1 filter mounted next to department switchgear R1 were presented in Tables 4÷6.

Table 4. The results of measurements of current, power, THDU and THDI in the supply system

Table 5. The results of measurements of current harmonics in the supply system

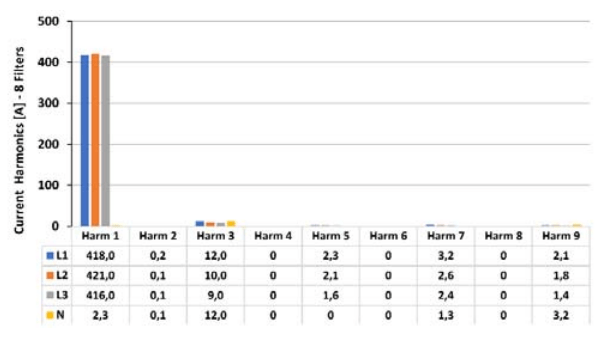

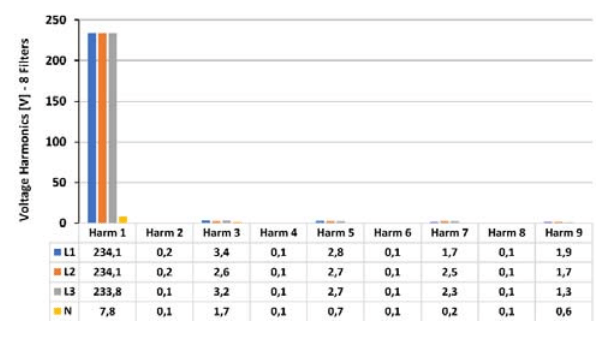

Whereas, the measurements with 8 filters mounted in department switchgears R1÷R8 were presented in the Tab. 7÷9.

Table 7. The results of measurements of current, power, THDU and THDI in the supply system

Table 8. The results of measurements of current harmonics in the supply system

Table 9. The results of measurements of voltage harmonics in the supply system

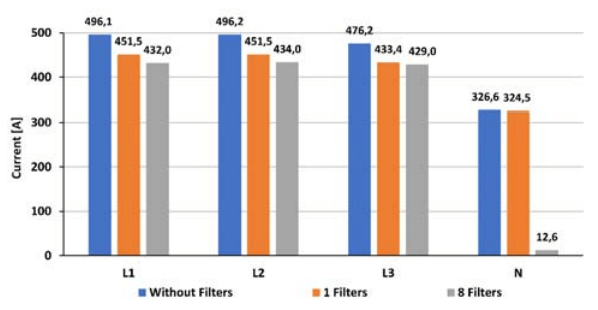

Based on obtained results of the measurements, Figure 4 presents the results of the measurements of current. Measuring data before installation of the filters and after installation of 1 filter and 8 filters were compared.

As a result of taken actions, power consumption in all phases noticeably decreased. In L1 and L2 phases, installation of additional 7 filters reduced current by additional 4%, whereas, no visible differences were observed in L3 phase. The greatest effect caused by installation of a set of 8 filters has been observed in the event of a neutral conductor – from 356,6 A to 12,6 A.

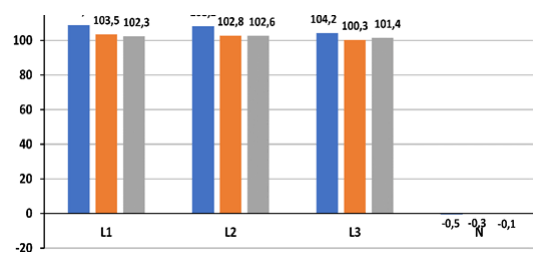

The comparison of the results of power consumption in the plant without installation of the filters and after installation of one filter and set of 8 filters was presented on Figure 5.

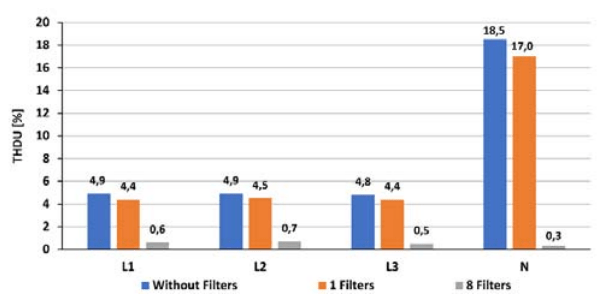

The results of the measurements of power consumption clearly show reduction of power generated for considered electric switchgears of the plant by 6,6 kW. Within a year, it enabled to save money and gave financial profit for the plant amounting to PLN 35000. Whereas, Figure 6 presents the results of the measurements of total harmonic voltage distortion (THDU).

Installation of one filter reduced THDU in phase N by 1,5%. In the event of L1-L3 phases, reliable changes have not been observed. Whereas, a set of the filters almost totally reduced parameters in all phases. Whereas, Figure 7 presents the results of the measurements of total harmonic voltage distortion.

Installation of one filter reduced THDI in L1-L3 phases by about 3 % and after installation of 8 filters, by on average 4%. In the even of phase N, 1 filter reduced THDI by 20%, and additional 8 filters practically completely minimized current distortions.

While assessing proposed solution, we must also analyse the impact of mounted AHF filters on reduction of higher harmonics. Figure 8 and 9 present the results of the measurements of current and voltage harmonics before assembly of the filters in the supply system of switchgears. Particular attention should be paid to high values of 3rd and 5th order harmonics, both for currents and voltages.

Installation of the first filter slightly reduced the values of 3rd order harmonics, by 5 and 11 A. A list of the results of measurements of current harmonics after installation of 1 filter was presented on Figure 10, whereas, Figure 11 presents the results of the measurements of voltage harmonics after installation of the first filter. No considerable changes have been observed on presented figure, which shows the necessity to still use additional filters in the supply system.

In order to achieve set goal of improvement of quality of electric energy in the network supplying the production plant, the number of installed filters was increased to 8. Figure 12 presents the results of measurements of current harmonics after installation of 8 active filters in the plant supply system. In the event of basic harmonics, the value of current was reduced by nearly 62 A in L1-L3 phases and the phase N was marginalized. Tertiary harmonics were reduced by over 90%.

The results of the measurements of voltage harmonics after installation of 8 filters in the plant were presented on Figure 13. Value for 3rd and 5th order harmonics was considerably improved.

Finally, based on 8 mounted filters, each one for single switchgear directly supplying the production devices, there was a notable impact on reduction of higher voltage and current harmonics. This reduction was a decisive factor of reduction of current in a neutral conductor and its overheating.

An important aspect of the presented modernization is the plant’s savings resulting from the decrease in power consumed as a result of installing filters. The recorded total power decrease of 6.6 kW, which, with the continuous operation of the plant resulting from the specificity of the production, results in the calculation of 6.6 x 24 houers = 158.4 kWh/day, i.e. 57,816 kWh/year in total. With the electricity rate applicable at the time of installation, PLN 0.6 /1kWh gives us PLN 34689.6 per year. Currently, due to the change in electricity purchase prices to PLN 1-1.2/1kWh, the savings reach even PLN 70,000 per year. The cost of purchasing such a device AHF at the time of implementation was PLN 23,000, i.e. 8 x PLN 23,000 = PLN 195,000. The gain from modernization is obvious and indisputable.

Conclusions

In recent years, intense changes occurred in technologies used by business entities. Obsolete devices were replaced with new ones and sometimes whole process lines equipped with electronic and power electronic devices were developed. New devices, although they consume less energy, need to be supplied in appropriate parameters due to too low or too high supply voltage. Therefore, Energy Distribution Operators are required to supply the consumers uninterruptedly and supply energy of appropriate qualitative parameters. More emphasis is put on duration of power cuts, but also on the value of supply voltage, which is specified by legal regulations. Significant and desired issue is the possibility of an analysis of voltage and current inside the network for the purpose of an analysis of archived measurements of current and voltage, which can be used to determine potential load capacity of an existing network, or to make a decision about modernization. On the other hand, the consumers are more and more aware of legal aspects within the scope of quality of electric energy that should be supplied, and access to various types of devices for archiving and analysis of voltage and current in the consumer system.

An analysis conducted based on the measurements showed occurrence of higher harmonics which considerably complicates operation of the networks and electric devices and causes increased power losses and problems with calculating voltage drops.

In order to eliminate interferences in the power grid of the production plant, considering specificity and need of reliability of power supply, it was assumed that the best method of elimination of interferences would be assembly of active filters AHF next to each switchgear supplying the production devices, that is, in the source of interferences.

The basis of modernization of considered industrial network in the production plant was assembly of harmonic filters to eliminate interferences. The effects included:

– Expected effect of current reduction in a neutral conductor by installing a set of 8 AHF filters, which decreased from 356,6 A to 12,6 A during current measurement for a neutral conductor,

– Reduction of total harmonic current distortion (THDI) after installation of the filters by about 4%,

– Decrease by 6,6 kW of power generated by the plant, which would give financial profit amounting to PLN 35000 within one year,

– Total reduction of harmonic voltage distortion (THDU) in all phases,

– Reduction of current distortions (THDI) in L1-L3 phases by about 3 % for installation of 1 filter and reduction by on average 4% after installation of 8 filters,

– In the event of a neutral conductor, one filter allowed to reduce THDI by 20% and additional 8 filters allowed to minimize current distortions in this conductor,

– Reduction by 90% of value of current of 3rd order harmonics and marginalization of other harmonics of higher orders.

The innovation presented in the presented research material was understood as the use of technical solutions in order to eliminate the problem of deformation of the power supply parameters in a simple and economical way by using a device to compensate for the generated deformations. This is a very well presented technical problem that has been solved by a simple technical application with a measurable financial effect.

The authors of this article think that constant development and modernization of industrial infrastructure will force the Distribution System Operators and technical services of the enterprises to constantly monitor the parameters of quality of electric energy. Development of smart networks and supply systems will be necessary. It will result in increased number of measuring points that will allow to follow the dynamics of changes of voltage and load currents. Archived data will also be significant, allowing to conduct an analysis of the parameters of electric energy in various supply points, in order to determine connections of additional sources of energy or making a decision about investment works connected with expansion of a network.

REFERENCES

[1] Dugan R. C,. McGranaghan M. F., Santoso S., Beaty H.W., Electrical Power Systems Quality, McGraw-Hill Education, Third Edition, 2012

[2] Povh D., Pregizer K., Weinhold M., Zurowski R., Improvement of supply quality in distribution systems, 14th International Conference and Exhibition on Electricity Distribution. Part 1. Contributions (IEE Conf. Publ. No. 438), 1997, 27/1-27/6, ISBN: 0-85296-674-1, doi: 10.1049/cp:19970494

[3] Mangold M., Weinhold R., Zurowski T., Voss, L., Power Conditioning Equipment for Improvement of Power Quality in Distribution Systems, cgti.org.br

[4] Lei X., Retzmann D., Weinhold M., Improvement of power quality with advanced power electronic equipment, DRPT2000. International Conference on Electric Utility Deregulation and Restructuring and Power Technologies. Proceedings (Cat. No.00EX382), 2000, 437-442, doi: 10.1109/DRPT.2000.855704

[5] Jensen M.M., Hansen H., Triplen harmonics in the low voltage network, Nordac conference, Stockholm, 8-9 September 2014

[6] Ceaki O., Seritan G., Vatu R., Mancasi M., Analysis of power quality improvement in smart grids, 10th International Symposium on Advanced Topics in Electrical Engineering (ATEE), 2017, 797-801, doi: 10.1109/ATEE.2017.7905104

[7] Ye G., Power quality in distribution networks: estimation and measurement of harmonic distortion and voltage dips. ISBN: 978-90-386-4405-9, 2017, Printed by Ipskamp Drukkers, Enschede

[8] Łukasik Z., Kozyra J., Kuśmińska-Fijałkowska A., Górecki R., Supplying electricity to service and business complexes, 2018 ELEKTRO, 2018, 1-6, doi: 10.1109/ELEKTRO.2018.8398295

[9] Wang B., Xu W., Pan Z., Voltage sag state estimation for power distribution systems, IEEE Transactions on Power Systems, 20(2), 2005, 806-812, doi: 10.1109/TPWRS.2005.846174

[10] Bollen M. H. J., Understanding Power Quality Problems Voltage Sags and Interruptions. IEEE Press, 2001, New York

[11] Sinexcel AHF One-Set and Multi-Set System (25~600A), User’s Manual BOM, No.: A81150060

[12] Bhattacharyya S., Power quality requirements and responsibilities at the point of connection, Ph.D. dissertation, Eindhoven Univertsity of Technology, 2011

[13] Vitaliy K., Nikolay T., Yevheniia K., Evaluating the Effect of Electric Power Quality upon the Efficiency of Electric Power Consumption, 2019 IEEE 2nd Ukraine Conference on Electrical and Computer Engineering (UKRCON), 2019, 556-561, doi: 10.1109/UKRCON.2019.8879841

[14] Sankaran C., Power quality. CRC press, 2017

[15] Gosbell V.J., Perera B.S.P., Herath H.M.S.C., New framework for utility power quality (PQ) data analysis. Proceedings AUPEC’01, Perth, 2001, 577–582

[16] Saxena D., Bhaumik S., Singh S., Identification of Multiple Harmonic Sources in Power System Using Optimally Placed Voltage Measurement Devices, IEEE Transactions on Industrial Electronics, 2014, 61(5), 2483-2492, doi: 10.1109/TIE.2013.2270218

[17] Łukasik Z., Kozyra J., Kuśmińska-Fijałkowska A., System of guaranteed power supply for the purposes of automated laser cutter in technologies of industrial cutting materials, 2020 ELEKTRO, 2020, 1-6, doi: 10.1109/ELEKTRO49696.2020.9130189

[18] Broshi A., Monitoring power quality beyond EN 50160 and IEC 61000-4-30, 9th International Conference on Electrical Power Quality and Utilisation, 2007, 1-6, doi: 10.1109/EPQU.2007.4424114

[19] Dolara A.; Leva S., Power Quality and Harmonic Analysis of End User Devices. Energies, 2012, 5(12), 5453-5466, doi: https://doi.org/10.3390/en5125453

[20] Hossain E., Tür M. R., Padmanaban S., Ay S., Khan I., Analysis and Mitigation of Power Quality Issues in Distributed Generation Systems Using Custom Power Devices, IEEE Access, 2018, 6, 16816-16833, doi: 10.1109/ACCESS.2018.2814981

[21] PN-EN 61000-3-12: 2012 Electromagnetic Compatibility (EMC) – Part 3-12: Limits for Harmonic Currents Produced by Equipment Connected to Public Low-Voltage Systems with Input Current 16A < and = 75A Per Phase

Authors: dr hab. inż. Jacek Kozyra, prof. URad., Uniwersytet Radomski im. Kazimierza Pułaskiego, Wydział Transportu, Elektrotechniki i Informatyki, ul. Malczewskiego 29, 26-600 Radom, Email: j.kozyra@uthrad.pl.; prof. dr hab. inż. Zbigniew Łukasik, Uniwersytet Radomski im. Kazimierza Pułaskiego Wydział Transportu, Elektrotechniki i Informatyki, ul. Malczewskiego 29, 26-600 Radom, E-mail: z.lukasik@uthrad.pl; dr hab. inż. Aldona KuśmińskaFijałkowska, prof. URad., Uniwersytet Radomski im. Kazimierza Pułaskiego Wydział Transportu, Elektrotechniki i Informatyki, ul. Malczewskiego 29, 26-600 Radom, E-mail: a.kusmińska@uthrad.pl; mgr inż. Piotr Tański, Baxtom Sp. z o.o., 06-500 Mława, ul. Browarna 4, Email: p.tanski@baxtom.com.

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 100 NR 4/2024