Published by 1.Nur HAMZAH, 2.Suryanto SURYANTO, 3.Muhammad ANSHAR, 4.Firman FIRMAN, 5. Muhammad Ruswandi DJALAL, 6. Muhammad Alif AL AFGAN. State Polytechnic of Ujung Pandang ORCID: 1. 0000-0002-7114-2247

Abstract. Waste is a major problem in big cities in Indonesia, one of which is Makassar City. Every year the amount of waste generated by the residents of Makassar City continues to increase, but this is not proportional to the capacity of the landfill. Therefore, researchers want to design a waste-to-energy power plant system in Makassar City or other words apply the waste-to-energy concept. The waste-to-energy concept aims to process waste into energy and reduce the volume of waste in landfills. Then the research method used is thermodynamic modelling using STEAG Ebsilon Professional version 13.02 software. From this analysis it was found that the capacity of the waste that can be burned is 742.648 tons/day, the thermal input of the incinerator is 39.011 MW, the thermal capacity of the boiler is 30.749 MW, the thermal efficiency of the waste-to-energy boiler with direct method 83.123 % and with indirect method 82.107 %, the mechanical power of the steam turbine is 10.816 MW, the heat duty of the high-pressure feed-water heater is 1,681.321 kW, the heat duty of the low-pressure feedwater heater is 1,780.234 kW, and the cooling duty of the air-cooled condenser 20.337 MW. This design has a net thermal efficiency of 24.110%, a gross plant heat rate of 12,683.130 kJ/kg, a net plant heat rate of 13,816.942 kJ/kg, an auxiliary load of 912.744 kW, a net plant power of 9.638 MWe, the specific fuel consumption 1.124 kg/kWh for each unit at the maximum load, and reducing municipal solid waste generation per year by 271,066.520 tons.

Streszczenie. Odpady stanowią poważny problem w dużych miastach Indonezji, jednym z nich jest Makassar City. Każdego roku ilość odpadów wytwarzanych przez mieszkańców Makassar City stale rośnie, jednak nie jest to proporcjonalne do pojemności składowiska. Dlatego badacze chcą zaprojektować system elektrowni przetwarzających odpady na energię w mieście Makassar, czyli innymi słowy zastosować koncepcję przetwarzania odpadów na energię. Koncepcja waste-to-energy ma na celu przetwarzanie odpadów na energię i zmniejszenie ilości odpadów trafiających na składowiska. Następnie zastosowaną metodą badawczą jest modelowanie termodynamiczne z wykorzystaniem programu STEAG Ebsilon Professional wersja 13.02. Z analizy tej wynika, że wydajność spalania odpadów możliwych do spalenia wynosi 742,648 ton/dobę, moc cieplna spalarni wynosi 39,011 MW, moc cieplna kotła wynosi 30,749 MW, sprawność cieplna spalarni -kocioł energetyczny metodą bezpośrednią 83,123 % i metodą pośrednią 82,107 %, moc mechaniczna turbiny parowej 10,816 MW, obciążenie cieplne wysokociśnieniowego podgrzewacza wody zasilającej 1681,321 kW, obciążenie cieplne niskociśnieniowego Moc podgrzewacza wody zasilającej wynosi 1780,234 kW, a wydajność chłodnicza skraplacza chłodzonego powietrzem 20,337 MW. Konstrukcja ta charakteryzuje się sprawnością cieplną netto wynoszącą 24,110%, współczynnikiem ciepła brutto instalacji wynoszącym 12 683,130 kJ/kg, współczynnikiem ciepła netto instalacji wynoszącym 13 816,942 kJ/kg, obciążeniem pomocniczym wynoszącym 912,744 kW, mocą netto instalacji wynoszącą 9,638 MWe, zużycie paliwa 1,124 kg/kWh na każdą jednostkę przy maksymalnym obciążeniu oraz ograniczenie wytwarzania odpadów komunalnych w skali roku o 271 066,520 ton. (Modelowanie termodynamiczne elektrowni przetwarzającej odpady na energię: studium przypadku w mieście Makassar w Indonezji)

Keywords: Thermodynamic-Modelling, Municipal Solid Waste, Power Plant

Słowa kluczowe: Modelowanie termodynamiczne, odpady komunalne, elektrownia

Introduction

So far, boiler heat energy sources use fossil fuels, while alternative energy sources that can be considered are waste energy sources and renewable energy sources.[1]. One part of waste energy is Municipal solid waste (MSW). MSW is a term usually applied to a heterogeneous collection of wastes produced in urban areas. Generally, urban wastes can be subdivided into two major components: organic and inorganic. The characteristics and quantity of the solid waste generated in a region are a function of the standard of living in the city or country. Wastes generated in developing countries have a large proportion of organic waste, while the wastes in developed countries are more diversified with relatively larger shares of plastics and paper [2]. Almost all economic sectors generate municipal solid waste. Some factors that influence high MSW generation are population and economic growth, education, occupation, consumption patterns, and gross domestic product per capita.

With a high gross domestic product, Indonesia generates large amount of annual municipal solid waste (SW) in ASEAN countries [3]. The annual production of municipal solid waste in Indonesia reaches 31 million tons with the waste composition including food waste at 39.23%, plastic at 18.11%, paper at 12.83%, wood at 12.16%, metal at 3.19%, cloth at 2.55%, glass 2.42%, leather 1.82%, and others 7.69% [4]. Meanwhile, Makassar City’s annual solid waste production reaches 1,023,710 tons with a composition of food waste at 54.70%, wood at 11.33%, plastic at 12.20%, paper at 6.78%, textile at 1.30%, glass at 1.15%, metal 1.07%, battery 0.62%, rubber 0.42% and other 10.43% [5]. Indonesian municipal solid waste has a high moisture content, volatile matter content, as well as carbon and hydrogen content, and contains more organic matter. Moisture content is a major factor impacting calorific value. The lower heating value on the wet basis of the entire municipal solid waste sample is 8.6 MJ/kg, which is not only relatively high compared with the average calorific value, but also above the World Bank-recommended calorific value minimum for waste-to-energy applications. Thermal conversion processes including incineration, pyrolysis, and gasification for heat, bio-oil, and syngas generation are already well established and are being employed in several countries [6] . MSW in Indonesia is suitable for waste-to-energy, whether combustion (incineration) or gasification-based [7].

The concept of waste-to-energy aims to process waste into energy and reduce the volume of waste in landfills. The most commonly used technology for converting waste into energy is incineration [8]. This is because incineration technology provides a more productive way of de-creasing the amount of urban solid waste that needs to be landfilled. The incineration of municipal solid waste can minimize its mass by 70% and volume by 90%, as well as electricity and heat recovery [9]. The purpose of this research is to get a waste-to-energy power plant model that is suitable and can solve the waste problems in Makassar City.

Fuel from waste

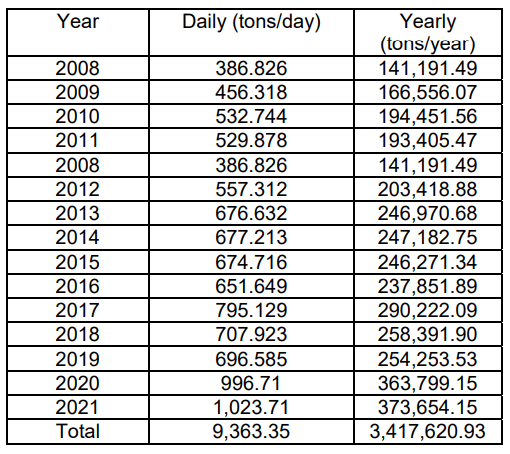

Makassar City has a daily potential power from the waste of 24.882-33.768 MWe with an LHV variation of 7-8.6 MJ/kg and an average amount of waste of 1,023,710 tons⁄day in 2021. Makassar City municipal solid waste production data is shown in Table 1.

Table 1. Makassar City municipal solid waste production data [5].

Waste to energy power plant description

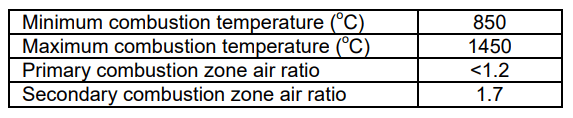

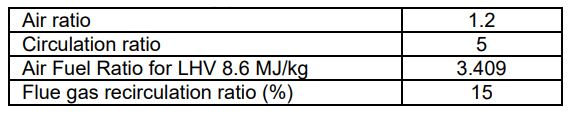

The Makassar City waste-to-energy power plant model consists of two identical units. Each of the two waste-toenergy power plant units has a high-pressure feedwater heater, a low-pressure feedwater, a deaerator, a steam turbine, an electric generator, a boiler, and four air-cooled condenser units. The estimated incinerator capacity of this power plant is 842.7 tons per day with an estimated power that can be generated of 20,482 – 25,164 MWe. The technical data of the Makassar City waste-to-energy power plant model is shown in Table 2.

Table 1. Combustion parameters [10, 11

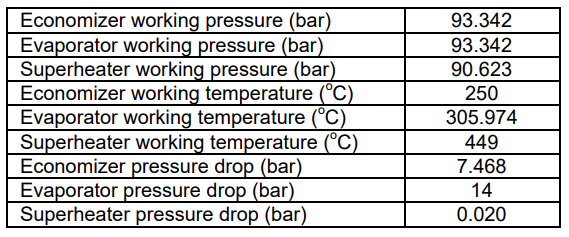

Table 3. Steam and water cycle parameters [12]

Table 2. Boiler Ratings [8],

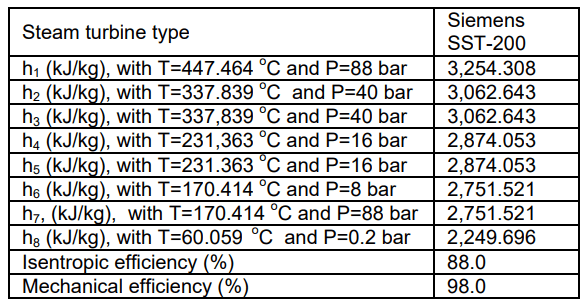

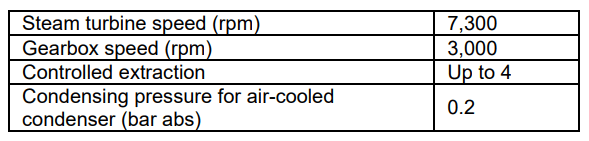

Table 3. Steam turbine parameters [13, 14]

Modelling and simulation of wate to energy power plant

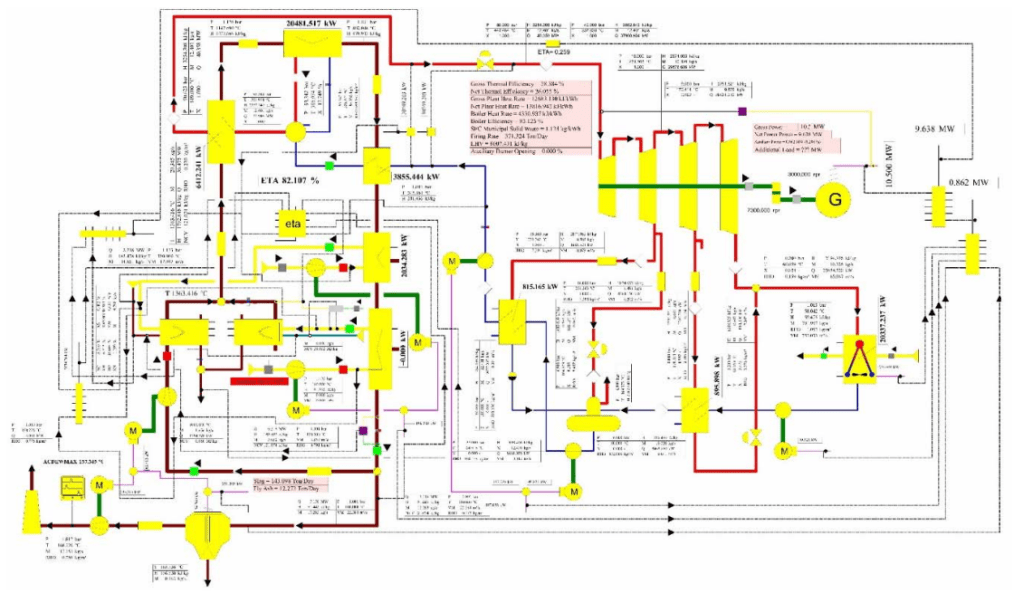

The modelling process was carried out by entering the technical data of the waste power plant into the model as shown in Fig. 1. The simulation process was performed to determine the performance of the model at the maximum load of each unit, which is 10.5 MWe. The performance observed in the model is the amount that can be burned, the thermal capacity of the boiler, the mechanical power of the steam turbine, the heat duty of the high-pressure feedwater heater, the heat duty of the low-pressure feedwater heater, the cooling duty of the air-cooled condenser, net thermal efficiency, net plant heat rate, auxiliary load, net plant power, and specific fuel consumption.

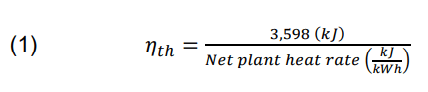

The equation used to calculate the net thermal efficiency of the model is as follows [15]:

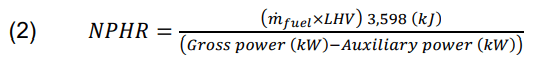

The equation used to calculate the net plant heat rate is as follows [15]

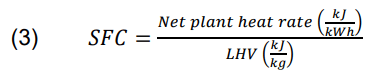

The equation used to calculate specific fuel consumption is as follows ([15]:

Result and discussion

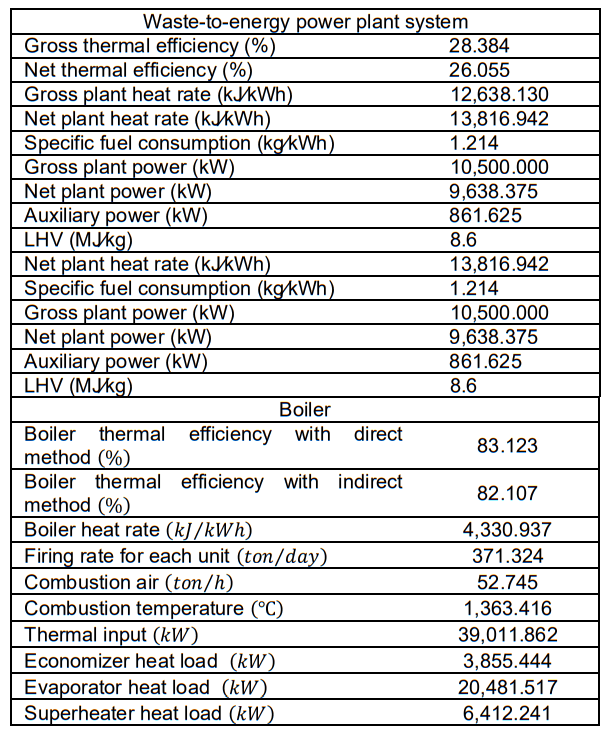

After conducting a simulation of the waste power plant model as shown in Fig. 1, the researchers got the results for each unit shown in Table 6.

Table 4 Simulation results of the waste-to-energy power plant model for each unit.

Waste to Energy Power Plant Efficiency

From the simulation results, it can be seen that the net thermal efficiency of the waste-to-energy power plant system model is 24.110%. These results are following research conducted by Mutz [16], which states that in general the thermal efficiency of waste-to-energy power plants is 20% this is in line with research conducted by Branchini [8], which states that in general the thermal efficiency of waste power plants ranges from 18% to 25% and in some cases more than 30%.

In addition, the model of the waste power plant system created by the researchers also uses a low air ratio to increase the net thermal efficiency of the waste power plant. This is in line with research conducted by Gablinge [11] which states that another benefit of using a low air ratio in a waste power plant is an increase in thermal efficiency.

Waste to Energy Boiler Efficiency

From the simulation results, it can be seen that the boiler thermal efficiency obtained is 83.123 % with the direct method and 82.107 % with the indirect method. These results are equal to the results of research conducted by Schu and Leithner [17], which state that the efficiency of the thermal waste-to-energy boiler is around 83%.

System Heat Balance

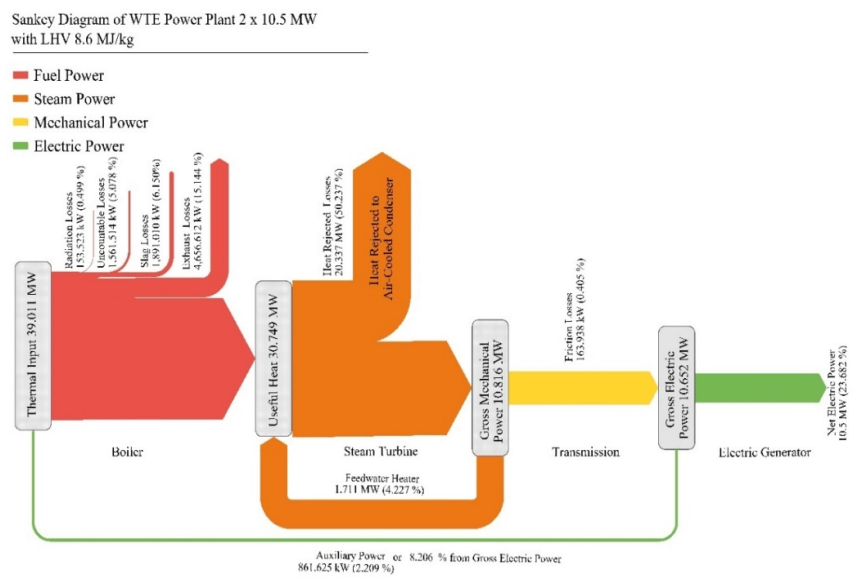

From the simulation results, it can be seen that the model of the waste-to-energy power plant system experiences the greatest heat losses in the air-cooled condenser and stack. The Sankey diagram of the model of the waste-to-energy power plant system can be seen in Fig. 2. The heat losses that occur in the air-cooled condenser are 20.337 MW or 50.237 % of the system. This happens because all the steam that has been used by the steam turbine and closed feedwater heater flows into the water-cooled condenser to change the phase from steam to water by removing the latent heat from the steam. So that the steam that has changed phase to water can flow back to the boiler. The heat losses that occur in the stack (exhaust losses) are 4.656 MW or 15.114 %. This is due to the temperature of the flue gas released into the atmosphere through the stack is high, which is 160 °C which then causes a lot of heat to be wasted from the flue gas.

Conclusion

The thermodynamic modelling using STEAG Ebsilon Professional software version 13.02 was presented. The model of the waste-to-energy power plant for Makassar City has an incinerator daily capacity of 371.323 ton/day at the maximum load of 10.5 MWe for each unit, the thermal capacity of the waste-to-energy boiler is 30,749 MW, the thermal efficiency of the waste-to-energy boiler is 83.123 %, the thermal efficiency of the waste-to-energy boiler, the mechanical power of the steam turbine is 10.816 MW, the heat duty of the high-pressure feedwater heater is 1,681.321 kW, the heat duty of the low-pressure feedwater heater is 1,780.234 kW, and the cooling duty of the aircooled condenser 20.337 MW, the net thermal efficiency is 26.055%, the net plant heat rate is 13,816.942 kJ/kWh, the auxiliary load is 912.744 kW, a net plant power of 9.638 MWe, the specific fuel consumption is 1.124 kg/kWh with LHV 8.6 MJ/kg. This waste-to-energy power plant model is suitable to be implemented and can solve waste problems in Makassar City.

REFERENCES

[1] P. Kolasiński, Use of the renewable and waste energy sources in heat storage systems combined with ORC power plants, Przeglad Elektrotechniczny, vol. 89, (2013),no. 7, pp. 277-279, 01/01 2013.

[2] H. Sudibyo, A. Majid, Y. Pradana, W. Wiratni, D. Aan, and A. Budiman, Technological Evaluation of Municipal Solid Waste Management System in Indonesia. 2017, pp. 263-269.

[3] P. Lestari and Y. Trihadiningrum, The impact of improper solid waste management to plastic pollution in Indonesian coast and marine environment, Marine Pollution Bulletin, vol. 149, (2019),no. p. 110505, 2019/12/01/ 2019.

[4] Ministry of Environment and Forestry Republic of Indonesia, Indonesia’s Municipal Solid Waste Production in 2021., (2022),no. 2022.

[5] Department of The Environment of Makassar City, “City Municipal Solid Waste Production Report in 2021,” Department of The Environment of Makassar City, Makassar2022.

[6] C. Ram, A. Kumar, and P. Rani, Municipal solid waste management: A review of waste to energy (WtE) approaches, BioResources, vol. 16, (2021),no. 2, pp. 4275-4320., 2021.

[7] Z. Zongao et al., Experimental study on characteristics of municipal solid waste (MSW) in typical cites of Indonesia, Progress in Energy & Fuels, vol. 8, (2020),no. p. 13, 04/16 2020.

[8] L. Branchini, Waste-to-Energy: Advanced Cycles and New Design Concepts for Efficient Power Plants. New York.: Springer International Publishing, , 2015.

[9] D. Cudjoe and P. M. Acquah, Environmental impact analysis of municipal solid waste incineration in African countries, Chemosphere, vol. 265, (2021),no. p. 129186, 2021/02/01/2021.

[10] C. e. a. Liu, C. Liu, T. Nishiyama, K. Kawamoto, and S. Sasaki, CCET Guidelines Se-ries on Intermediate Municipal Solid Waste Treatment Technologies Waste to Energy Incineration., IETC Technology for Environment and In-stitute for Global Environmental Strategies., (2020),no. 2020.

[11] R. Strobel, M. H. Waldner, and H. Gablinger, Highly efficient combustion with low excess air in a modern energy-from-waste (EfW) plant, (in eng), Waste Manag, vol. 73, (2018),no. pp.301-306, Mar 2018.

[12] J. B. Kitto and S. C. Stultz., J. B. Kitto and S. C. Stultz, Eds. Steam: Its Generation and Use, 41st ed. ed. Babcock & Wilcox Company, 2005.

[13] L. Branchini, Waste-to-Energy, Advanced Cycles and New Design Concepts for Efficient Power Plants. Switzerland Springer International Publishing 2015.

[14] S. AG, “Siemens Steam Turbine Portfolio,” 2019.

[15] Black and Veatch, Power Plant Engineering. Boston: Springer, 1996.

[16] D. Mutz, D. Hengevoss, C. Hugi, and D. Hinchliffe, Waste-toEnergy Options in Municipal Solid Waste Management – A Guide for Decision Makers in Developing and Emerging Countries. 2017.

[17] R. Schu and R. Leithner, “Waste to energy–Higher efficiency with external superheating,” in Proceedings 2nd International Symposium on Energy from Biomass and Waste, Venice, Italy, 2008

Authors: Assoc Prof Nur Hamzah,, Politeknik Negeri Ujung Pandang, Jl. Perintis Kemerdekaan KM 10 Makassar Indonesia Email: hamzah_said@poliupg.ac.id

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 100 NR 2/2024. doi:10.15199/48.2024.02.22