Published by Unipower AB, Metallgatan 4C, 44132 Alingsås, Sweden. Email: info@unipower.se

Introduction

This case study explores how advanced power quality measurement technology facilitated the diagnosis of severe power quality disturbances in a bus depot. These disturbances, which neither the bus operator nor the bus manufacturer initially attributed to electrical quality issues, were ultimately traced to deficiencies in the depot’s charging infrastructure.

Background

A bus depot, integrating both AC and DC charging infrastructure, was experiencing operational disruptions. The facility contained AC chargers (22 kW) designated for minibuses and DC fast chargers (200 kW) for larger electric buses. Depot operators observed that the AC chargers were intermittently failing when the DC chargers where in use. These issues impacted vehicle availability and overall operational efficiency. The root cause of these disruptions remained undetermined until an extensive power quality analysis was conducted.

Diagnostic Assessment

A power quality investigation revealed that the power disturbances originated from the absence of necessary electrical filters in the DC chargers. Without these filters, the operation of DC chargers induced significant harmonic distortions in the local voltage, interfering with the stability of the AC charging units.

Power Quality Analysis

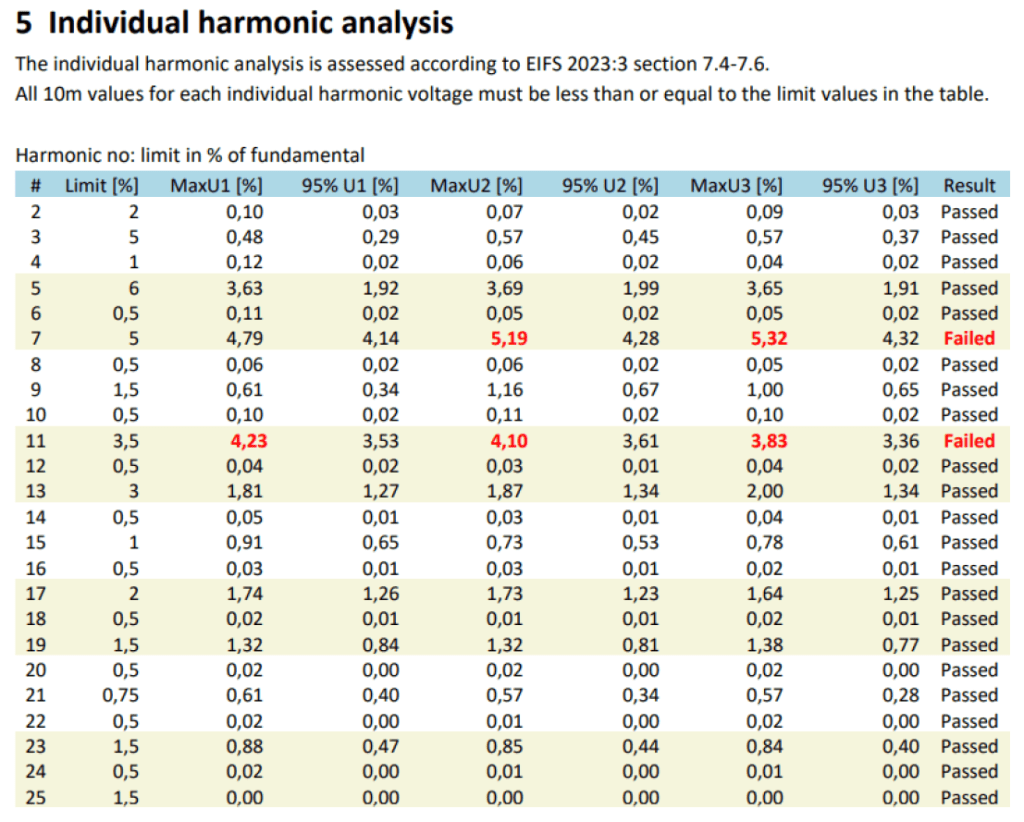

The measurement data indicated that the Swedish power quality standard (EIFS) had been exceeded due to harmonic content in the 7th and 11th harmonic. EIFS is a local adaption of the European EN50160 norm.

Additionally, the analysis revealed that the power factor was significantly below optimal levels, causing energy inefficiencies within the depot’s electrical distribution system.

Implementation of Mitigation Measures

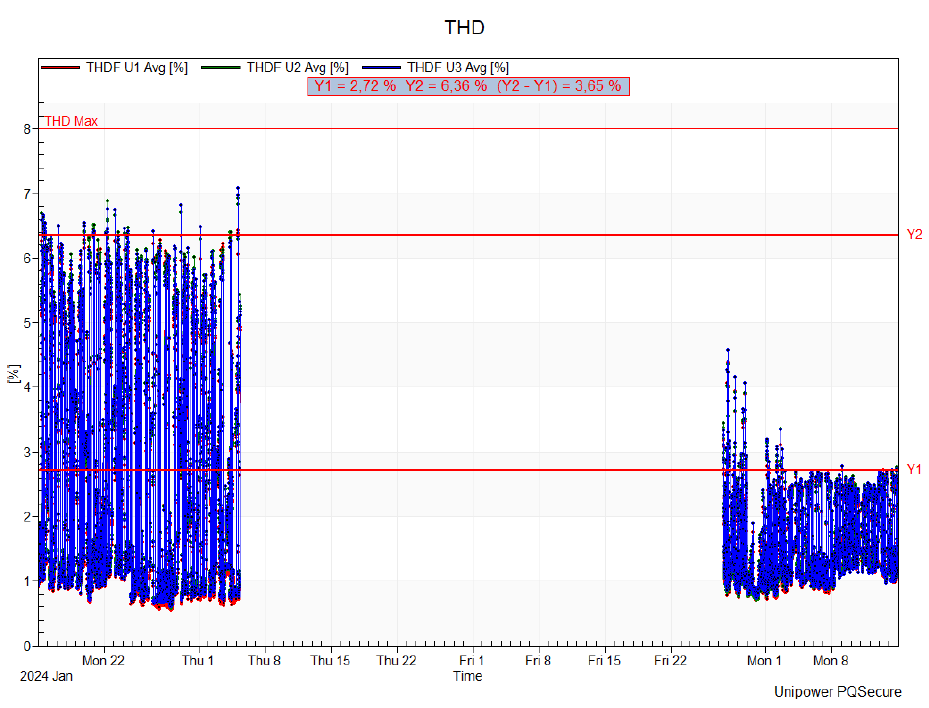

Following the identification of these power quality issues, the DC charger manufacturer installed appropriate electrical filtering solutions. A subsequent measurement campaign was conducted to assess the effectiveness of these interventions. The results demonstrated a significant improvement:

• Substantial reduction in harmonic distortions, bringing them within regulatory compliance limits.

• Power factor improvement from 88% to 97%, enhancing overall energy efficiency by 9%.

Lessons Learned & Next Steps

• Implement continuous monitoring: Regularly measure power factor, harmonic distortion, and other vital parameters to detect potential issues before they escalate.

• Evaluate expansion opportunities: As the electric fleet grows, continuously assess whether the existing filters, chargers, and electrical network remain adequate.

• Strengthen collaboration with manufacturers: Ongoing dialogue with both bus and charger suppliers helps ensure that proper filters and components are in place from the outset.

• Analyze economic implications: Beyond energy savings, conduct a return-on-investment (ROI) analysis of the filter installation and the improvements in system stability.

• Educate relevant staff: Ensure that electrical technicians and depot managers understand fundamental power quality principles, enabling rapid response to emerging anomalies.

This case study underscores the critical role of advanced power quality diagnostics in identifying and resolving electrical disturbances. By systematically analyzing power parameters and implementing targeted mitigation strategies, significant improvements in charging infrastructure reliability and energy efficiency were realized. The findings highlight the necessity of continuous power quality assessments for ensuring optimal performance and compliance in electric bus depots.

About Unipower: Unipower AB offers a wide range of products for Power Quality measurements and Smart Grid systems.

Originating from a Swedish ABB company in the mid 80’s, Unipower has developed a competitive edge within the field of Power Quality and Smart-Grid solutions. We focus on norm compliance equipment, with a special focus on the requirements for power generation, transmission and distribution.

Our product lines reach from traditional portable PQ analysers to fully integrated and automated Power Quality Management systems for continuous supervision of the energy supply.

Website: unipower.se