Published by Samira KHANAHMEDOVA, Azerbaijan State Oil and Industry University

ORCID: 0000-0001-8862-1570

Abstract. The article discusses ways to reduce losses to increase efficiency in electric machines. The amount of energy loss is determined by the efficiency coefficient. The issues of changing the size of an electric machine under electromagnetic loads with a constant power source and constant voltage are considered. It is taken into account that reducing energy losses reduces the degree of environmental pollution, which contributes to improving life around the world. The analysis of the dimensions of an electric machine is given, that is, the possibility of reducing electricity losses by changing its dimensions within possible limits, taking into account the design capabilities of electric machines. The analysis is based on the law of similarity, which is widely used in the design of electric machines.

Streszczenie. Rozważane są kwestie zmiany wielkości maszyny elektrycznej pod obciążeniem elektromagnetycznym ze stałym źródłem zasilania i stałym napięciem. Bierze się pod uwagę, że zmniejszenie strat energii zmniejsza stopień zanieczyszczenia środowiska, co przyczynia się do poprawy życia na całym świecie. Podano analizę wymiarów maszyny elektrycznej, czyli możliwość zmniejszenia strat energii elektrycznej poprzez zmianę jej wymiarów w możliwych granicach, biorąc pod uwagę możliwości konstrukcyjne maszyn elektrycznych. Analiza opiera się na prawie podobieństwa, które jest szeroko stosowane w projektowaniu maszyn elektrycznych. (Niektóre zagadnienia dotyczące zwiększania wydajności maszyn elektrycznych)

Keywords: efficiency, electromechanical energy, electric motor, mass of the active part.

Słowa kluczowe: sprawność, energia elektromechaniczna, silnik elektryczny, masa części aktywnej.

Introduction

The increase in efficiency in the process of electromechanical energy conversion is an urgent and technically difficult issue for all types of electric machines. 99% of all electricity generated is obtained through electric generators – by converting mechanical energy into electrical energy. Electric motors convert 65% of this energy back into mechanical energy. It should be noted that the distribution energy is spent on losses in the system elements (power lines, transformers and cables) in the amount of 10% of the energy at a distance from the source (power plant) to the actuator. Thus, the issue of reducing electricity losses remains relevant [1, 2, 6, 11].

This issue remains a complex technical and economic issue and the decision must take into account the cost of the electric motor. The cost of an electric machine depends primarily on the materials used, which determine the type, size and characteristics of the machine, and also depend on the economy of the state (the country from which the machine is made). Suppose losses in the machine are reduced by increasing its dimensions. In that case, it is necessary to consider comparing prices for materials used and labor costs in combination with electricity (saving electricity during engine operation). A sharp disproportionate increase in electricity prices compared to the prices of electric machines and other electrical equipment also affects the change in the principles of designing electric machines [3, 4, 7, 9, 11].

The solution of the task

For the design of electric machines and ensuring efficient operating modes, much attention is paid to the possibilities of increasing the efficiency, and the issues of changing its size under electromagnetic loads at a constant power source and constant voltage are considered. In addition, it must be borne in mind that reducing energy losses reduces the degree of environmental pollution, which contributes to improving life around the world [12, 21].

When analyzing the dimensions of an electric machine, that is, the possibility of reducing electricity losses by changing its dimensions within possible limits, it should be borne in mind that it is necessary to take into account the design capabilities of electric machines. The analysis is based on the law of similarity, which is widely used in the design of electric machines.

Main part

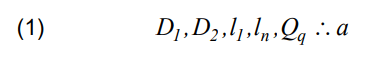

According to the similarity theory, when the linear dimensions of the active part of an electric machine change by “a” times, the inner diameter of the stator core Dd and the outer diameter Dx, the length of the stator core l1, the total length of the wires l2 and the polar distribution 𝜏q will change proportionally by “a” times [12, 15, 18, 24].

where .˙. – the sign of proportionality.

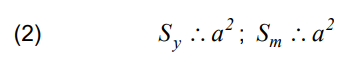

The cross-sectional area of the copper in the Sy slot and the cross-section of the magnetic conductor, see the change in linear dimensions proportional to the square “a”:

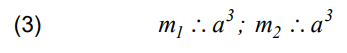

The mass of the active part of the copper plate m1 and the mass of the magnetic conductor m2 are proportional to the cubic degree of change in linear dimensions:

For analysis in the initial approximation, it can be taken into account that the dimensions of the inactive parts of the electric machine (housing, cushions, shaft …) do not increase proportionally to the increase in the volume of the active parts of the machine [7, 23]. The weight of the machine, the materials used and the labor costs are also proportional to the volume of the machine in the first approximation.

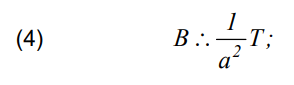

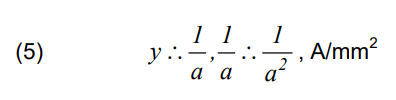

Considering the above, by increasing the size of the active parts of the asynchronous machine, let’s look at the analysis of the possibility of increasing the efficiency. Thus, the electrical and mechanical ratings – power, voltage, speed, type of protection and cooling – remain unchanged. In this case, according to similarity theory, when the linear dimensions of the machine change by a factor of “a”, the electromagnetic charges, induction B and current density y will change as follows [11, 17, 23]:

If the rated voltage of the motor is constant, and if the density of induction and current changes in accordance with expressions (4) and (5), then the number of windings of the stator coil will change as follows,

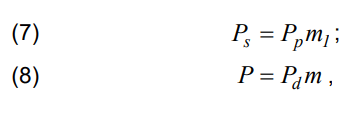

for an electric machine whose dimensions are increased by a factor of “a”, the losses in the windings PS, steel PP, and the main electromagnetic loads B vary depending on expressions (4) and (5) and are calculated by the following expressions:

where PS and Pd – the corresponding losses of the machine in question.

The efficiency of the engine is calculated:

where P – the mechanical rated output power of the engine; Pp – the total losses in the machine, including losses in the stator and rotor; Ps – losses in steel.

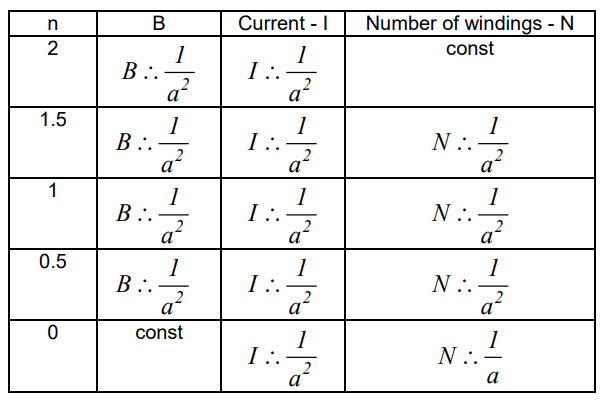

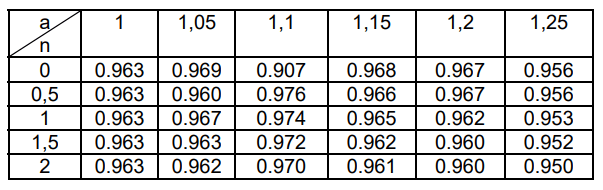

Note that mechanical friction losses and ventilation losses depend on the size change. In this case, the dependences of electromagnetic charges and the number of windings of phase N on the indicator “n” and the coefficient of change in linear dimensions from the indicator “a” are shown in Table 1.

Table 1. Indicators of the number of windings of electromagnetic charges and phase

According to the expression (9), changes in the efficiency coefficient are performed for two industrially significant engines. The first engine (A) was mass-produced of industrial significance, the quantity data is taken from the reference table; the second engine (B), having high power, the quantity data is taken from the reference book. The rated power of the engine (B) is also more than 100 times the power of the engine (A). Nominal numbers of engines under investigation:

(A): 22 kV; 400V; 50Hz; 2p=2; P1=1098W;

(B): 2500 kV; 6000V; 50HZ; 2p=2; P=202 kW.

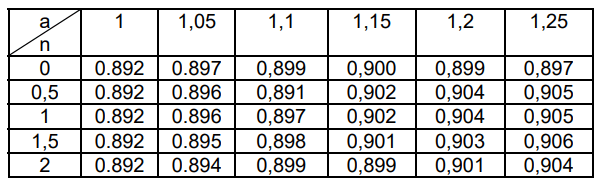

For comparative analysis, it is necessary to analyze the dependence of the efficiency coefficient on the parameters “a” and “n” for electrical machines (A) and (B). The main calculations are performed in the MATLAB/Workspace program.

a=1;1.05;1.1;1.15;1.2; 1.25;…

n=0:0.05:2

% for engine A

P=22; V=400V; f=50; 2p=2; P1=1098

% for engine B

P=2500; V=6000V; f=50; 2p=2; P1=202

% efficiency

teta=P./(P+P1)

teta (A)=22000/22980+1098a+597a

teta (B)=2500/2530.8+31.259a+201a

The results obtained are shown in Table 2 and 3. Based on the table, it obtains characteristics for comparative analysis.

Table 2. Results of calculations of efficiency coefficients for the engine (A)

Table 3. Results of calculations of efficiency coefficients for the engine (B)

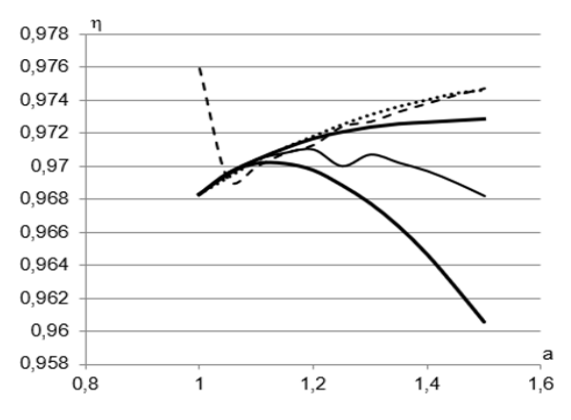

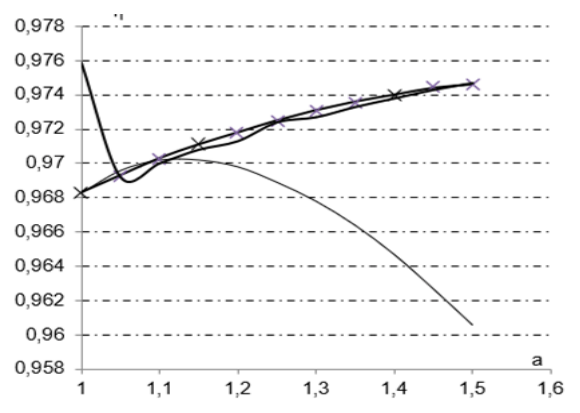

The characteristics for the engine (A) and engine under study (B) are shown in the fig.1 and fig.2.

It can be seen from Figures 1 and 2 that the efficiency depends on the linear dimensions of the engine (value “a”) and the change in electromagnetic loads in and (parameter “n”). For each case, you can find the maximum function.

The efficiency coefficient for the engine (a) can be increased by 3.171%, provided that the linear dimensions are increased by 2 times and (N=2) losses are reduced by 18.5%. At the same time, the mass of active materials increases by 8 times.

From Table 2 and Fig. 2, it can be concluded that with linear similarity of the efficiency coefficient 2p=2, the efficiency coefficient only increases. This is because the efficiency increases with increasing rated power, which is confirmed by the theory of similarity (electric machines and transformers).

Conclusion

The article analyzes ways to reduce losses to increase efficiency in electric machines. The issues of changing the dimensions of an electric machine under electromagnetic loads with a constant power source and constant voltage are considered. The analysis of the dimensions of an electric machine is given, that is, the possibility of reducing electricity losses by changing its dimensions within possible limits, taking into account the design capabilities of electric machines. The analysis is based on the law of similarity, which is widely used in the design of electric machines.

A comparative analysis was performed for a commercially available engine and a high-power engine under study. The dependence of the efficiency coefficient on the parameters “a” and “n” for electric machines is analyzed. The main calculations were performed in the MATLAB/Workspace program.

The efficiency of the engine under study can be increased by 3.171%, provided that the linear dimensions are increased by 2 times and (N=2) losses are reduced by 18.5%. At the same time, the mass of active materials increases by 8 times.

With a linear similarity of the efficiency coefficient 2p=2, the efficiency coefficient only increases. This is because efficiency increases with an increase in rated power, which is confirmed by the similarity theory).

REFERENCES

[1] S. A Celtek, S.Ruşen, G. Karanfil Effects of Electric on the energy efficincy. Department of Energy Systems Engineering, Karamanoğlu Mehmetbey University, Karaman. 8th International Ege Energy Symposium and Exhibition, 2016, https://www.researchgate.net/publication/313767458_Effects_of_ElectricMotors_On_The_Energy_Efficiency

[2] A. T. De Almeida, F. J. T. E. Ferreira, J. A. C. Fong, and C. U. Brunner, “Electric motor standards, eco-design and global market transformation,” Conf. Rec. – Ind. Commer. Power Syst. Tech. Conf., pp. 1–9, 2008.

[3] S.M. Lu, “A review of high-efficiency motors: Specification, policy, and technology,” Renew. Sustain. Energy Rev., vol.59, pp. 1–12, 2016.

[4] A. Zabardast and H. Mokhtari, “Effect of high-efficient electric motors Celtek et al. / 8th International Ege Energy Symposium and Exhibition – 2016 on efficiency improvement and electric energy saving,” 3rd Int. Conf. Deregul. Restruct. Power Technol. DRPT 2008, no. April, pp. 533–538, 2008.

[5] “World Energy Outlook 2016, “IEA, Paris, License: CC BY 4.0 (report); CC BY NC SA 4.0 (Annex A), 2016. [Online]. https://www.iea.org/reports/world-energy-outlook-2016.

[6] “Energy Efficiency 2022” IEA, Paris, 2022, vol. License: CC BY 4.0. https://www.iea.org/reports/energy-efficiency-2022.

[7] “World Energy Outlook 2022, “IEA, Paris, License: CC BY 4.0 (report); CC BY NC SA 4.0 (Annex A), 2022. https://www.iea.org/reports/world-energy-outlook-2022.

[8] “Electric motors and variable speed drives” https://commission. europa.eu/energy-climate-changeenvironment /standards-tools-and-labels/products-labellingrules-and-requirements/energy-label-and-ecodesign/energyefficient-products/electric-motors-and-variable-speeddrives_en (accessed 21/04/2023, 2023).

[9] “Energy Efficiency Improvements in Electronic Motors and Drives,” 2000, https://doi.org/10.1007/978-3-642-59785-5.

[10] Kazovskiy Ye.YA. Perekhodnyye protsessy v elektricheskikh mashinakh peremennogo toka- M.L.: Izd. ANSSSR, 1962.-624 s.

[11] Jacek F. Gieras Electrical Machines 1st Edition. CRC Press; December 18, 2020, 452 pages. ISBN-10: 0367736942.

[12] Ryszard Palka and Marcin Wardach , Design and Application of Electrical Machines. May 2022., Pages: 352. https://doi.org/10.3390/books978-3-0365-4324-6

[13] Postnikov N.M., Ostapchuk L.B., Postnikov V.N. Godograf toka i parametry massivnogo rotora asinkhronnoy mashiny // Elektrichestvo, -1975.-№1, pp.38-42

[14] Paul C. Krause, Oleg Wasynczuk, and Scott D. Sudhoff.. Analysis and Design of Electric Machines. Publication date: 2013. Publisher: Wiley. 720 pages.

[15] T.J.E. Miller. Synchronous and Asynchronous Machines. Pergamum Press.1989. 448 pages

[16] R.Saidur. A review on electrical motors energy use and energy savings. Renewable and Sustainable Energy Reviews, Volume 14, Issue 3, April 2010, Pages 877-898

[17] L Nagel. What is the Average Efficiency of an Electric Motor, July 02, 2023, https://www.tytorobotics.com/blogs/articles/what-is-theaverage-efficiency-of-an-electric-motor

[18] Wilde, C. U. Brunner,”Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems”, International Energy Agency, Working paper, 2011.

[19] “Electric Motors and Variable Speed Drives – Standards and legal requirements for the energy efficiency of low-voltage three-phase motors”, ZVEI – Zentralverband Elektrotechnikund Elektronikindustrie e.V., Division Automation – Electric Drive Systems, Frankfurt, December 2010, 2nd Edition.

[20] Vagati, “The synchronous reluctance solution: a new alternative in AC drives,” 20th International Conference on Industrial Electronics, Control and Instrumentation, 1994. IECON ’94., Bologna, 1994, pp. 1-13 vol.1.

[21] Lipo, T. A., “Synchronous reluctance machines – a viable alternative for AC drives.”, Wisconsin Electric Machines and Power Electronics Consortium, Research report, 1991.

[22] “Low voltage Process performance motors according to EU MEPS”, ABB catalog, October 2014

[23] “Rare Earths”, S. Geological Survey, Mineral Commodity Summaries, January 2016.

[24] Guglielmi, B. Boazzo, E. Armando, G. Pellegrino and A. Vagati, “Magnet minimization in IPM-PMASR motor design for wide speed range application,” 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, 2011, pp. 4201-4207.

[25] “Motor technologies for higher efficiency in applications – An overview of trends and applications”, Danfoss Power Electronics – Danfoss VLT drives PE-MSMBM, November

Authors: Khanakhmedova Samira Alkhadi. Doctor of Philosophy in Engineering, Associate Professor of the Electromechanics Depart- ment of the Azerbaijan State University of Oil and Industry. Baku city, Azadlyg avenue 20,Email: samira.khanahmedova@asoiu.edu.az.

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 100 NR 9/2024. doi:10.15199/48.2024.09.32