Published by 1. Magdalena UDZIK1, 2. Krzysztof ŁOWCZOWSKI1, 3. Józef Jacek ZAWODNIAK2, Politechnika Poznańska, Instytut Elektroenergetyki (1), Stowarzyszenie Elektryków Polskich Oddział Gorzowski (2) ORCID: 10000-0002-4959-2751.; 2. 0000-0002-4196-0492 Scopus: 3. 36620039300

Abstract. The paper presents selected issues related with MV/LV transformer stations to which local energy sources – photovoltaic power plants are connected. General parameters of pole-mounted stations are presented to outline issues related with the operation resulting from the connection of renewable sources to the LV grid. General principles of transformer selection and the risk of its overheating are also presented. This article is 1 of 2 parts of the analysis of the impact of connecting PV sources to the low voltage distribution network on the risk of overloading the transformer station.

Streszczenie. W artykule opisano wybrane zagadnienia związane ze stacjami transformatorowymi SN/nn, do których przyłączane są lokalne źródła energii – elektrownie PV. Scharakteryzowano ogólne parametry stacji słupowych, celem przybliżenia problematyki eksploatacyjnej wynikającej z przyłączenia źródeł odnawialnych do sieci nn. Przedstawiono także ogólne zasady doboru transformatora oraz ryzyko jego przegrzania. Niniejszy artykuł to 1 z 2 części analizy wpływu przyłączenia źródeł PV do sieci dystrybucyjnej niskiego napięcia na ryzyko przeciążenia stacji transformatorowej (Przyłączenie źródeł fotowoltaicznych do sieci dystrybucyjnej niskiego napięcia a ryzyko przeciążenia stacji transformatorowej. Część 1: Charakterystyka stanu istniejącego).

Keywords: MV/LV transformer stations, photovoltaic home system, overloading transformers, distribution network

Słowa kluczowe: stacje transformatorowe SN/nN, przydomowe elektrownie PV, przeciążanie transformatorów, sieć dystrybucyjna

Introduction

Technological progress, the need to reduce the emission of harmful substances (eg. CO2, NOx) to the atmosphere, and rising electricity prices cause a rapid increase in the connected photovoltaic micro-installations to distribution networks. Connecting such sources may bring benefits not only to prosumers, but also to the power grid [1]. Therefore, more and more areas are emerging with a high concentration of photovoltaic (PV) micro-installations. Too many connected photovoltaic sources may, however, lead to problems with the reliability of the power system – e.g. voltage deviations at consumers, increase in losses in transformers due to a large share of harmonics, increase in short-circuit currents, bidirectional power flow [2 – 4].

The increasing number of electric energy sources connected to low voltage circuits in the form of photovoltaic power plants means that the distribution system operators have a new task ahead of them. It is related to the fact that the existing power system (designed as an unidirectional) should be adapted to bidirectional electricity transmission while maintaining the required power quality. Theoretically, the task seems to be simple, but due to a number of parameters that need to be adjusted, it is not. One of such network elements that should be adapted to the new operating conditions are medium to low voltage (MV/LV) transformer stations.

This issue should be approached comprehensively, not selectively, focusing only on the selection of a transformer for new operating conditions. In other words, adapting stations to new operating conditions is also an analysis of the following possibilities of:

• load capacity of the MV and LV circuits, including substation switchgear,

• switching capacity of the apparatus installed on the MV and LV side,

• adaptation the transformer protection against overload and short-circuits.

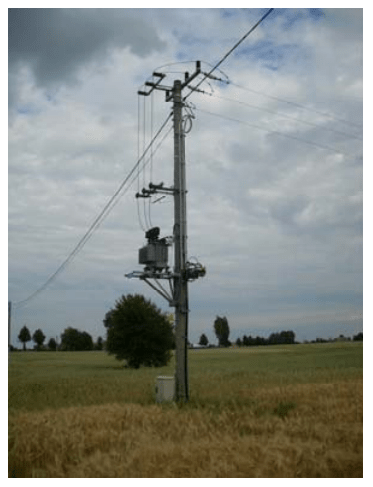

The biggest challenge is the adaptation of overhead stations built in the last century, on the basis of developed catalogs [5], which are intended to supply rural or urban consumers. The electrical and mechanical technical parameters will determine the possibility of adapting MV/LV transformer stations to the new operational requirements. The article focuses on the oldest structures, still found mainly in rural areas, so these are pole stations of the type: ZH 15 (pol. ŻH 15), STS – 20/100, STS – 20/250 and newer ones of the STN type, the album of which has been modernized in 2020.

This article aims to examine and analyze the impact of connecting PV sources on transformer stations. It also draws attention to the challenges related to adapting the existing infrastructure of the transformer station to bidirectional electricity transmission. In the following, the first part of the article will be presented, covering the characteristics of general technical parameters of pole stations, general rules for selecting a transformer and presenting the risk of its overheating.

Construction and electrical parameters of selected overhead MV / LV transformer stations

The ZH 15 (pol. ŻH 15) type transformer stations can still be operated by the commercial power industry, although in the coming years they should be replaced with new ones. According to [5], the ZH 15 station could be installed in the medium voltage network through the straight-line or act as a terminal pole for the MV line. The station consists of two 12 m long reinforced concrete poles to which metal structural elements are attached, creating a characteristic goal system (Fig. 1). Up to four low voltage circuits could be lead out of the station.

STS – 20/100 transformer stations can be adapted to new operating conditions, provided that there are economic reasons, or replaced with new ones. According to [5], the STS – 20/100 station could be installed in the medium voltage network as an end pole for the MV line. The station consists of two 12 m long reinforced concrete poles, connected with each other with a vertex wedge, and in the center by a platform structure for the transformer. The silhouette of the station resembles a capital letter A (Fig. 2). As in ZH 15 station, up to four low voltage circuits could be lead out.

The STS – 20/250 station, in accordance with [5], could be installed in the medium voltage network as an end pole for the MV line. Two 12 m long reinforced concrete poles are connected with each other with an apex wedge, and the metal structures of the station are joined by the poles connected in this way (Fig. 2). Up to four low voltage circuits could be lead out of the station. STS – 20/250 transformer stations will probably be qualified for modernization in the near future, but before each modernization an economic analysis of profitability should be carried out.

Technical (electrical) parameters of all stations described above are the station are presented in Table 1 [5].The electrical parameters of the stations given in Table 1 result from the assumptions made in the typification, but in actual facilities they may be different, because the station may have already been modernized.

Table 1. Electrical parameters of the transformer stations [5]

STN transformer stations with a transformer of up to 630 kVA [6] will be adapted to the new operating conditions. Therefore, it seems reasonable to characterize the technical (electrical) parameters of the station in more detail.

The STN station according to [6] (Fig. 3) can be installed in the MV network supplied by an overhead line (bare, non-insulated conductors), cable or the so-called universal cable. Low voltage circuits can be led out from the switchgear: stationary, free-standing, cable cabinet or pole-mounted disconnectors, with a fully insulated conduit or a cable. The supporting structure is a one spun pole with a length of 8.2 m to 12.0 m and an apex force from 6 kN to 35 kN. Structural elements of the substation were designed with the requirements of the polish standards: N SEP-E-003 and PN-E-05100-1:1998. On the MV side, the substation can be equipped with: fuses, switchgear, voltage and current transformers. Technical (electrical) parameters of the station are presented in Table 2 [6].

Table 2. Electrical parameters of the STN transformer station [6]

In 2020, the album of pole transformer stations [6] developed in 2007 was amended to adapt to the requirements of PN-EN 50341-1: 2013-03, PN-EN 50341-2- 22:2016-04 in the field of structure dimensioning. Additionally, typing solutions for the station foundation were designed in accordance with PN-EN 1997-1 Eurocode 7 [7]. The main changes made to the album [7]: a 13.5 m long spun rod was used and the poles with a point force of 6 kN and 10 kN were eliminated, the new constructions were developed, including transformer platforms, increasing their permissible load capacity, as shown in Table 3.

Table 3. Permissible load on the transformer platform [7]

Configuration of the substation switchgear and substation fuse parameters

In the case of low voltage substation switchgears, apart from the electrical parameters of the switchgear and busbars, the configuration of the substation switchgear, an important element affecting the integration of PV sources may be an important element – in particular, the way of connection between fuse bases or switchgear. The most common variant of the connection system in existing stations is one in which individual low voltage circuits are led out of the transformer and protected with station fuses (Fig. 4a). The variant shown in Figure 4b will probably be more advantageous now resulting from low voltage PV installations, enabling the protection of the transformer against overload on the low voltage side.

While the principle of selecting a substation fuse for the protection of low voltage circuits is generally known, it is worth describing the substation inserts for protecting MV/LV transformers, type gTr. First of all, on this type of fuse-links the rated current is not given, as on linear ones, but the apparent power of the transformer in kVA, which is the basis for the selection of protection. They are designed to protect transformers up to 1000 kVA with a nominal voltage of the secondary side up to 400 V, they can be installed in fuse bases and switching devices (size 2 and 3 fuses), while size 4a fuses only in switching devices. Their currenttime characteristics are appropriately matched to the thermal load capacity of the transformer, therefore this type of inserts can conduct the current:

• 1.3 times higher than the rated current for ten hours

• 1.5 times higher than the rated current for two hours [8]

According to [8], the selectivity of operation between the gTr type fuses and the protection of the linear circuits (gL, gG) is satisfied if the fuse value (gTr) is equal to or greater than the fuse-link rated current (gL, gG), i.e. gTr in [kVA ] ≥ gL or gG in [A].

General rules for selecting a transformer

A transformer is a substation element that receives the most attention and rightly so, because its oversizing and undersizing have specific consequences, not only of an electrical nature, but also of an economic nature. The rules for selecting a transformer to suit the operating conditions in the network are generally known, and they consists in determining:

• its working conditions – in the power industry, only outdoor transformers are used,

• type of insulation (oil, dry). Transformers with dry insulation are used only in exceptional cases, mainly in places where there is a need to meet legal requirements, e.g. in the field of environmental protection and fire protection,

• nominal voltage values (primary side 15; 20; 30 kV, secondary 0.4 kV),

• connection groups:

• Yz – used to supply low voltage networks in the TN-C system (where the functions of the protective conductor PE and the functions of the neutral conductor N are performed by one common protective-neutral conductor PEN) with significant load unbalance in units with a capacity of up to 250 kVA,

• Dy – used to supply low voltage networks in the TN-C system with significant load unbalance in units with a power above 315 kVA,

• Yy – in the TN-C system with load unbalance up to 10%,

• short-circuit voltage (nominal, increased), which affects: the value of the short-circuit current, voltage fluctuations during load changes, energy losses,

• rated power of the transformer,

• voltage regulation [9, 10].

The MV/LV transformer achieves the greatest efficiency when its load is approx. 0.5-0.6 of the rated power, because in this range the variable (electric) losses are equal to the constant losses (in iron) [11]. Theoretically, the selection seems simple, but in real network conditions, the power demand changes in a specific period of time, e.g. a day or a month. So, when selecting the transformer for the actual operating conditions, one should take into account some over- and undersizing of the unit. And since it is unavoidable, it can take place within a certain – acceptable period of time, without fear of deterioration of the transformer’s insulation system.

Daily or monthly power demand data can currently be obtained from the measurement systems installed at the transformer station. Balancing electricity meters are used to measure the actual energy flow and to record data describing power quality. The currently required averaging period for recording energy profiles is 15 minutes. It is worth emphasizing that these are real data, measured at a given station, which take into account not only electricity consumption but also its production. Thus, they provide an excellent basis for analyzing transformer selection in a more automated manner using calculation programs.

Voltage regulation in MV/LV transformers on the secondary side is usually carried out in the range of +/- 2/3 tap position. This adjustment is made when the transformer is disconnected, by means of the tap charger located above the cover of the transformer tank. The main disadvantage of this solution is the inability to perform voltage regulation while the transformer is operating, and the derivative – inability to perform voltage regulation in real time.

Another solution to the problem of voltage regulation may be the use of a unit with an on-load tap changer and automatic voltage regulation [12]. Such regulation is most often performed in the range of +/- 10% of the nominal voltage of the unit. The cost of transformer increases, but it ensures greater voltage stability in the LV network, especially when local energy sources are connected to the network, which may cause voltage unbalance (maximum 3% [13]). The increasing number of local energy sources, e.g. from home photovoltaic installations, also increases the risk of exceeding the permissible voltage level. This makes it necessary to expand the network to cope with the new working conditions. Installing a transformer with an on-load tap changer – automatic voltage regulation, although it is more expensive compared to a regular unit, allows the voltage to be kept within the acceptable limits. MV/LV transformers with on load voltage regulation under load will be used more and more in the future due to the increasing number of installed photovoltaic cells and the bidirectional flow of energy in the grids.

The pole-mounted energy storage are the solution that allows the use of the full potential of the installed sources and the voltage and frequency regulation without the need to replace the transformer and disconnect the consumers when changing the position of the tap changer. These energy storage system is a collection of equipment used for the controlled import and export of electricity to and from the power system on the LV and MV sides. The significant advantages of such a solution are the integration of the energy storage with the existing pole station, limitation of significant network investments and the possibility of ensuring the continuity of energy supply and maintaining its quality parameters. Additionally, these energy storages become another measuring point in the network [14].

Risk of overheating of distribution transformers

Temperature has a key influence on the transformer’s life span. Oil transformers, which are most often used in the power industry, have a cellulose-oil insulation system. As standard, the insulation of the coil conductors is made of paper, and the entire active part is immersed in oil, which has two functions: insulation and cooling. The oil facilitates the removal of heat from the core and windings, transfers heat from these elements to the walls of the tank, and from there through convection and radiation to the outside. The greater the power of the unit, the more heat must be dissipated [15]. Due to the cooling system, transformers can be divided into units with natural and artificial cooling, but forced cooling is not commonly used at the MV/LV level. Natural cooling consists of removing heat due to the temperature difference of the insulating liquid and air, while the artificial cooling is used, inter alia, fans that increase the flow rate of the coolant. The article focuses on ON-AN (Oil Natural-Air Natural) oil-cooled transformers, where the active parts are cooled by natural convection and radiation.

The PN-EN 60076-2: 2011 standard clearly defines the allowable temperature rise in relation to the environment for oil transformers operating continuously. If the transformer has a tap changer with a regulation range of +/- 5%, the temperature increases specified in the standard apply to each tap. In the case of operation with the rated power for the ON-AN oil transformer with class A constant insulation (long-term temperature 105⁰C), the permissible temperature increases at individual points are [16]:

• 60⁰C for the oil in the upper layer,

• 65⁰C for windings,

• 78⁰C for the hottest spot (hot spot).

The standard does not specify numerical values of temperature increases for the core, electrical connections (except windings), and structural elements of the tank. It is only mentioned that these elements cannot reach a temperature that will damage adjacent parts or cause unacceptable aging of the oil. The normal working range of the transformer is specified by the standard as -25⁰C to 40⁰C. If the temperature in the place of installation exceeds the lower or upper limit value, the permissible temperature rise specified in PN-EN 60076-2: 2011 is reduced by the value of the exceedance.

The two main causes of failure of distribution transformers are random phenomena and progressive aging processes. The random phenomena include, among others lightning strikes, short-circuits caused by animals, manufacturing errors of the structure, or work in extreme weather conditions. The aging processes result from the long operation time of the unit, and their acceleration is influenced by improper operating conditions. These include, first of all, long-term overloading of transformers, especially in summer, when the ambient temperature is higher, which causes excessive heating of the transformer.

Each oil transformer can be overloaded, thus obtaining a power greater than the rated power. However, as the load on the unit increases, increases the losses and so does the temperature. Thus, overloading transformers causes faster insulation degradation and an increase in the probability of dielectric damage. Sudden and uncontrolled temperature rise may cause oil leakage from the transformer due to the expansion of the liquid under the influence of temperature. Additionally, it is possible to exceed the liquid’s ignition temperature, which is about 160⁰C for oil. The increase in the temperature of the device in the case of overhead stations, described in the article, also depends on environmental factors such as the ambient temperature, wind speed and the level of sunlight of a given unit, which are not specified in the IEC 60076-2: 2011. On the other hand, in the case of indoor stations, one should remember about proper heat dissipation from the room, ensuring e.g. natural ventilation.

Summary

The article presents selected issues related to MV/LV transformer stations to which local energy sources are connected in the form of home PV installations. Attention was drawn to the challenges faced by distribution companies related to the adaptation of the existing electricity infrastructure to the bidirectional flow of energy in the grid and the increased share of installed photovoltaic cells. The focus was on elements of MV/LV transformer stations, the task of which has become to transform electricity in two directions, not one as before.

A station is not only a transformer, but also medium and low voltage circuits and switchgear of the station, which should be adapted to the new operating conditions (two-way transformation). These issues, although generally outlined in the article, require individual analysis before the final decision on the scope of the station modernization, as well as the issue of the need to protect the transformer against overload and short-circuits on the low voltage side. In particular, if:

• the number of connected PV power plants is conducive to the production of significant value of power,

• electricity consumption by consumers is currently negligible,

• cross-sections of the conductors and cables used in low voltage circuits allow the transformer to enter the full amount of electricity produced by PV power plants.

Due to significant amount of material to be presented, the paper is divided into two parts.

REFERENCES

[1] Hoke A., Komor P., Maximizing the Benefits of Distributed Photovoltaics, The Electricity Journal (2012); No. 25(3), 55-67

[2] Fernández G., Galan N., Marquina D., Martínez D., Sanche, A., López P., Bludszuweit H., Rueda J., Photovoltaic Generation Impact Analysis in Low Voltage Distribution Grids, Energies (2020); No.13(17):4347

[3] Gandhi O., Sampath Kumar D., Rodríguez-Gallegos C.D., Srinivasan D., Review of power system impacts at high PV penetration Part I: Factors limiting PV penetration, Solar Energy (2020); No. 210: 181-201

[4] Patil A., Girgaonkar R., Musunuri S. K. Impacts of increasing photovoltaic penetration on distribution grid — Voltage rise case study. International Conference on Advances in Green Energy (ICAGE) 2014, Thiruvananthapuram, India, 2014: 100-105

[5] Zawodniak J.J, Transformer stations on pylon – formerly and today, Przegląd Budowlany (2011)

[6] Energolinia in Poznań. Album of MV / LV STN, STNu pole transformer stations with a transformer up to 630 kVA on spun poles, volume I, PTPIREE 2007

[7] Energolinia in Poznań. Album of MV / LV pole-mounted transformer stations with transformers up to 630 kVA on spun poles, volume I, PTPIREE 2020

[8] Bessei H. Power Fuses : Manual for User of Low-voltage and High-voltage Fuses. NH/HH-Recycling, Germany 2011

[9] Kochel M, Niestępski S. Elektroenergetyczne sieci i urządzenia przemysłowe. Oficyna Wydawnicza Politechniki Warszawskiej 2003

[10] Strojny J, Strzałka J. Projektowanie urządzeń elektroenergetycznych. Uczelniane Wydawnictwo NaukowoDydatktyczne AGH 2001

[11] Mitew E. Electrical Machines. Volume 1 i 2. Zakład Poligraficzny Politechniki Radomskiej 2005

[12] Distribution transformer with on-load tap changer. http://www.sgbsmit.pl/wp-content/uploads/RONT – Transformator-zpodobciazeniowym-przelacznikiem-zaczepow.pdf – accessed June 2022

[13] Standard PN-EN 50160:2019 Voltage characteristics of electricity supplied by public electricity networks

[14] Catalog of energy storage systems. https://www.energetykarozproszona.pl/media/event_activity_presentations/12.40_Fidrocki_B%C5%82a%C5%BCej_Techniczne_Mo%C5%BCliwo%C5%9Bci.pdf – accessed August 2022

[15] Guo J, Fan K, Yang B, Yang H, Peng Q, Zheng H., Investigation on Temperature Rise Characteristic and Load Capacity of Amorphous Alloy Vegetable Oil Distribution Transformers with 3D Coupled-Field Method, Machines (2022); 10(1): 1-15

[16] International Standard IEC 60076-2:2011 Power transformers – Part 2

Authors: mgr inż. Magdalena Udzik, Politechnika Poznańska, Instytut Elektroenergetyki, ul. Piotrowo 3a, 61-138 Poznań, E-mail: magdalena.udzik@put.poznan.pl; dr inż. Krzysztof Łowczowski, Politechnika Poznańska, Instytut Elektroenergetyki, ul. Piotrowo 3a, 61-138 Poznań, E-mail: krzysztof.lowczowski@put.poznan.pl; Józef Jacek Zawodniak, Stowarzyszenie Elektryków Polskich Oddział Gorzowski, Grobla 9, 66-400 Gorzów Wielkopolski, E-mail: jj.zawodniak@wp.pl

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 99 NR 8/2023. doi:10.15199/48.2023.08.31