Published by Doh-Young PARK1, Jacek F. GIERAS2,3

Korea Institute of Machinery and Materials, Daejeon, Korea (1), UTP University of Science and Technology, Bydgoszcz, Poland (2), Korea Electrotechnology Research Institute, Changwon, Korea (3),

Abstract. The paper presents the Incheon Airport Maglev Line (IAML) in South Korea connecting Incheon Airport with Yeongjong Island. The paper focuses on construction of elevated track and infrastructure, magnetic levitation and propulsion, cars of trainset, power consumption and operating costs.

Streszczenie. W artykule przedstawiono kolej magnetyczną Incheon Airport Maglev Line (IAML) w Korei Płd. łączącą port lotniczy Incheon z wyspą Yeongiong. Szczególną uwagę zwrócono na konstrukcję toru umieszczonego na estakadzie, lewitację magnetyczną, napęd silnikami liniowymi, wagony, pobór mocy oraz koszty operacyjne. (Kolej magnetyczna Incheon Airport Maglev Line)

Keywords: maglev line, Incheon Airport, linear motors, power consumption, operating costs.

Słowa kluczowe: kolej magnetyczna, port lotniczy Incheon, silniki liniowe, pobór mocy, koszty operacyjne.

Introduction

Korea Urban Maglev Program started in December 2006 at Korea Institute of Machinery and Materials (KIMM) in Daejeon. The construction of passenger carrying service of 6.1-km, low-speed Incheon Airport Maglev Line (IAML) started on February 3, 2016. It was preceded by complete and thorough system interface tests, part of which were required by the regulations.

The IAML is a completely passive system with attraction electromagnets and primary units of the linear induction motor (LIM) installed in vehicles, while reaction rails for electromagnets and LIMs are installed in the track [1].

The IAML connects Incheon International Airport Transportation Center (IIATC) with Yongyu station in Yeongjong Island. There are 6 stations: (1) IIATC, (2) LongTerm Parking, (3) Administration Complex, (4) International Business Center, (5) Water Park, (6) Yongyu Station.

Construction

The double-track elevated guideways of the IAML are installed on concrete pillars. The highest elevation is 24.5 m, the maximum gradient is 45 ‰ and the minimum curve radius 50 m. There is a maintenance depot and control center in the vicinity of Yongyu Station. The route map is shown in Fig. 1. The trainset on elevated guideway is shown in Fig. 2.

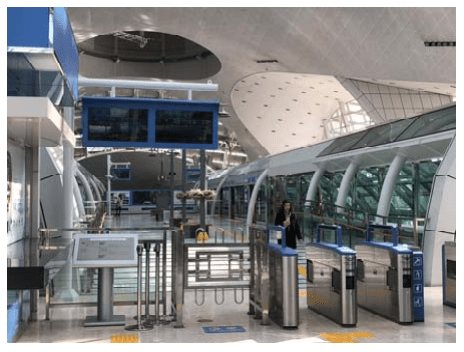

The Incheon Airport Transportation Center Station is shown in Fig.3. The travel is free of charge. The first maglev train leaves the IIATC at 7:30 and the last train at 20:15. The first train leaves the Yongyu Station at 7:31 and the last train at 20:01. The trains operate in 15 min intervals. The travelling time is 12 min. for 6.1-km trip. There are 103 trips per day

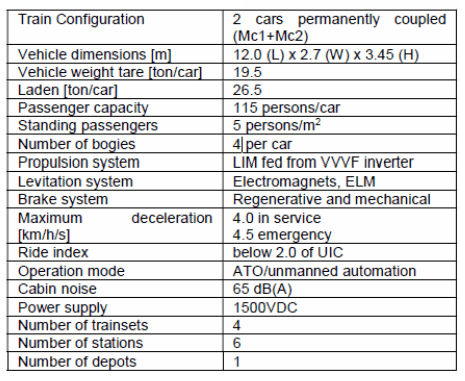

The operator is the Airport Railroad Corporation. There are two tracks in parallel. The track gauge is 1850 mm (Fig. 4). The line is electrified at 1500V DC. The electric power is fed to the vehicle with the aid of two contact rails mounted at each side of the concrete elevation (Fig. 5). There are two sliding contacts per vehicle. The average speed is 30.5 km/h including stops at the stations, cruising speed is 80 km/h, and maximum speed is 110 km/h. Specification of IAML are given in Table 1 [1,2,3].

Table 1. Specification of IAML [1,2]

1 – sliding contact mounted in the bogie, 2 – contact rail, 3 – insulator.

The construction cost per 1 km was US$ 37.8 million in 2009 [2]. For comparison, the average cost per 1 km of light railway (wheel-on-rail), rubber tire shuttle or monorail in Korea was US$ 41.4 million in 2009 [2].

Magnetic levitation and propulsion

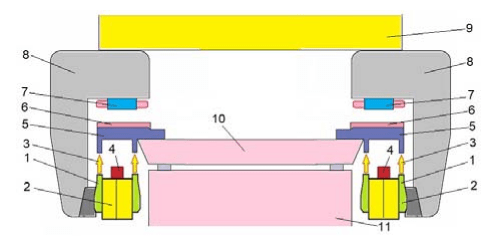

The IAML uses electromagnetic levitation (EML), i.e., attraction forces between electromagnets and reaction rails and LIM propulsion. The suspension and propulsion system is shown in Fig. 6.

Suspension electromagnets, which produce attraction force have steel core with U-cross-section. The nominal air gap between the electromagnets poles and steel reaction rail is 8 mm. The constant levitation gap is maintained by controlling the electric current fed to the windings of electromagnets with the aid of sensors and controllers. Fig.7 shows the car-mounted suspension electromagnet and part of the primary unit of the LIM mounted above the electromagnet. Both electromagnets and the primary units of LIMs are air cooled.

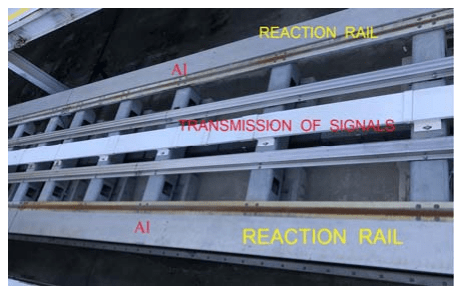

Stable levitation is maintained for at least 30s after power failure with the aid of the backup battery system, which is eco-friendly and easy to maintain. The steel rail for suspension electromagnets is also a part of the reaction rail (secondary unit sometimes called “back iron”) for the LIM (Fig. 6). To reduce the impedance of the reaction rail and improve all performance characteristics of the LIM, the active surface of the steel reaction rail is furnished with a high-conductivity plate. Copper is too expensive metal, so aluminum plate is used almost in all LIM-driven vehicles around the world. The IAML also uses aluminum plate on the active surface of the steel reaction, which is visible in Fig. 4. The nominal air gap (mechanical clearance) between the primary unit core of the LIM and aluminum plate is 13 mm. The LIM is fed from a VVVF inverter. There are four LIMs per each side of the car. Each LIM and four suspension electromagnets create a suspension-propulsion unit (Fig. 8).

1 – steel core of suspension electromagnet, 2 – winding of electromagnet, 3 – suspension force, 4 – air gap sensor, 5 – steal reaction rail for suspension electromagnets and LIM, 6 – aluminium cap to reduce the resistance of reaction rail for LIM, 7 – primary unit of LIM, 8 – bracket for electromagnets (part of bogie), 9 – car body, 10 – base of the track (sleeper), 11 – concrete beam.

1 – steel core of the electromagnet, 2 – coil of the electromagnet, 3 – three-phase winding of the primary unit of the LIM, 4 – bogie of the car, 5 – steel reaction rail for suspension electromagnet (part 5 of Fig. 6). Photo taken in the maintenance depot.

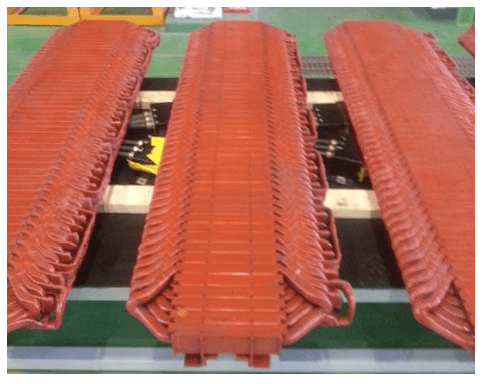

The are 4 propulsion LIMs installed at each side of the car, altogether 8 LIMs per car. Each LIM has 6 poles. LIMs are fed from VVVF inverters. LIMs are shown in Fig. 9. Propulsion system can provide maximum acceleration of 4.0 km/h/s and maximum deceleration of 4.5 km/h/s in the case of emergency. The empty weight of each vehicle is 19.5 tons and the full weight with passengers is 26.5 tons.

1,2,3,4 – electromagnets, 5 – three-phase winding of the primary unit of the LIM. Photo taken in the maintenance depot.

Cars

The design of the car body incorporates traditional Korean curvature and honeycomb pattern (Fig. 10). The lightweight car body has been made with the aid of single skin aluminum extrusion technology. Electro-hydraulic and pneumatic brake systems provide excellent braking performance. The lighting and illumination system is entirely composed of LEDs to save energy. Dimmed windows protect the privacy of neighbourhoods the trainset passes by. The dimming effect is the result of an electrified gel sandwiched between two thin pieces of glass. As the electric current increases, the gel darkens and as it drops, the gel lightens.

Operating costs

Operating costs of IAML include [2,3]:

• employment cost;

• electric power consumption cost;

• maintenance cost;

• administrative cost.

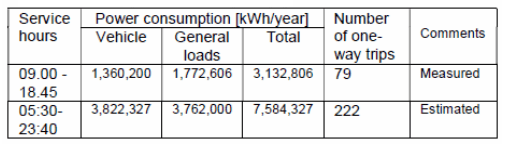

Electric power cost is the cost of electricity consumed by vehicles and general electric loads (Table 2). The maglev vehicle consumes electric power for propulsion, levitation, plugging (braking) and operation of service equipment. The general electric loads include lighting, fans, communication equipment, PA, and electricity consumed by buildings and stations for passenger service operation.

Maintenance cost consists of utility cost (electric power consumption), commission/service (outsourcing) cost, material cost, repair cost, train maintenance, communication charge and supplies expense. Administrative expense is generated by general management of the administration division. It includes insurance premiums, cost, and service charges for cleaning and security.

Breakdown of operating costs is given in Table 3. Salaries of employees contribute to almost 70% of the total costs.

Table 2. Annual Power Consumption [2]

Table 3. Breakdown of operating costs for IAML [2]

Conclusions

• The IAML is a low-speed EML passenger transportation system driven by LIMs with completely passive track.

• The construction cost of 1 km of double-track line was US$ 37.8 million in 2009, i.e., 9.5% less than the construction of 1 km of traditional light railway.

• The annual operating costs of IAML are about US$ 6.3 million.

REFERENCES

[1] ECOBEE: the cutting edge technology, Korea Institute of Machinery and Materials (KIMM), Daejon.

[2] K. B. Lee, S. K. Ma,.B. C. Shin, D. Y. Park, Study of calculation of standard operating costs of Incheon Airport Maglev Line, Transportation Systems and Technology, 4 (2018), nr 1, 5-18.

[3] D.Y. Park, B. C. Shin, H. Han, Korea’s Urban Maglev Program, Proc. of the IEEE, 97 (2009), nr. 11,

Authors: Dr inż. Doh Young Park, Korea Institute of Machinery and Materials (KIMM), Center for Urban Maglev Program, Daejeon, Korea, E-mail: dypark@kimm.re.kr ; prof. dr hab. inż. Jacek F. Gieras, IEEE Fellow, UTP University of Science and Technology, Dept of Electrical Engineering, Al S. Kaliskiego 7, 60-965 Bydgoszcz, Poland, E-mail: jacek.gieras@utp.edu.pl

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 95 NR 6/2019. doi:10.15199/48.2019.06.01