Published by Tural Aliyev1, Aydin Aliyev2,Azerbaijan State Oil and İndustry University, Baku, Azerbaijan ORCID: 1. 0000-0003-0751-3952, 2. 0000-0002-1631-0543

Abstract. This article aims to shed light on the critical aspects of power transformer assessment and proposes avenues for improvement in current methodologies, emphasizing the need for a more comprehensive and integrated approach to ensure the reliability and longevity of power transformers in the evolving landscape of the power system.

Streszczenie. Celem tego artykułu jest rzucenie światła na krytyczne aspekty oceny transformatorów mocy i zaproponowanie możliwości ulepszenia obecnych metodologii, podkreślając potrzebę bardziej wszechstronnego i zintegrowanego podejścia w celu zapewnienia niezawodności i trwałości transformatorów mocy w zmieniającym się krajobrazie systemu elektroenergetycznego . (Nowoczesne metody oceny stanu technicznego transformatorów mocy)

Keywords: power transformers, technical condition assessment, diagnostic and monitoring systems, informative parameters.

Słowa kluczowe: transformatory mocy, ocena stanu technicznego, systemy diagnostyczne i monitorujące, parametry informacyjne.

Introduction

Power transformers are considered among the most crucial elements determining the reliability of electrical equipment in the energy system. The seamless and secure transmission of required power in its full form depends on the condition of individual windings and the absence of flaws. The persistence of power transformers in their operational functions during the exploitation process is essential to prevent the occurrence of extensive consequences, such as accidents, arising from faulty conditions in the energy system. Currently, the application of existing diagnostic methods to evaluate the technical condition of transformers assists in ranking them based on their operational state, contributing to the reduction of costs allocated for operation and maintenance.

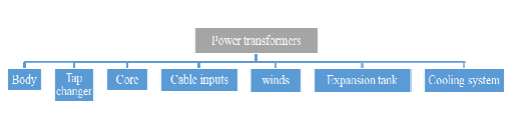

Figure 1 illustrates the essential elements of power transformers, each of which, when compromised, can lead to disruptions in the transformer’s operational regime.

Relevance of the Problem and Related Research

This article discusses the assessment of the technical condition of power transformers, which hold critical importance for the electricity supply system. The seamless and secure transmission of electrical energy, from the production site to consumers, relies on the flawless operation of these transformers, ensuring the overall durability and reliability of the power system. Research indicates that various methods employed to assess the technical condition of power transformers do not fully align with real production conditions and are frequently used beyond normative periods.

Despite normative documents suggesting a service life of 25 years, results show that over 40% of transformers exceed this timeframe. According to the assessment by CIGRE, transformers with a damage rate exceeding 3% are not considered economically viable for continued operation.

The failure of power transformers poses the potential for accidents, power interruptions, equipment malfunctions, and can result in significant economic and environmental damages. This emphasizes the importance of evaluating their technical condition and underscores the need for a contemporary analysis of methods and tools.

The purpose of the research in this article is to propose an analysis of modern methods and tools for assessing the technical condition of power transformers, aiming to ensure the reliable and effective operation of these devices—one of the most important research objects in the field of power systems. This endeavor contributes to the development of technologies in the field of electrical power and represents a significant step toward enhancing the security of the energy system.

Methods

Assessment of the Technical Condition of Power Transformers: Comparative Analysis of Diagnostic Methods Among the existing diagnostic methods for evaluating the technical condition of power transformers, preference is given to methods that can be applied while they are under operational stress, i.e., without removing them from service. These methods include:

1. Method for Analyzing the Technical Condition of Transformers Based on Thermal Imaging: This method involves analyzing the technical condition of transformers based on thermal images, allowing for assessments to be made while the transformers are under load.

2. Method for Evaluating the Technical Condition of Transformers through Vibration Analysis: This approach involves analyzing vibrations to assess the technical condition of transformers, enabling evaluations to be conducted while the transformers are in operation.

3. Method for Assessing the Technical Condition of Transformers through Extracted Oil Analysis: This method entails analyzing oil extracted from the transformer to assess its technical condition, offering the advantage of conducting evaluations without taking the transformer out of service.

These methods represent advancements in the field, providing the capability to assess the technical condition of power transformers without disrupting their operational status. The utilization of thermal imaging, vibration analysis, and extracted oil analysis contributes to a more comprehensive understanding of transformer health and facilitates proactive maintenance strategies.

Assessing the technical condition of power transformers based on thermal imaging is a sufficiently complex process.

This is because, while transformers perform their operational functions, their core and windings generate a natural heat flow, and any localized faults created are encompassed by this heat flow, introducing a certain level of difficulty.

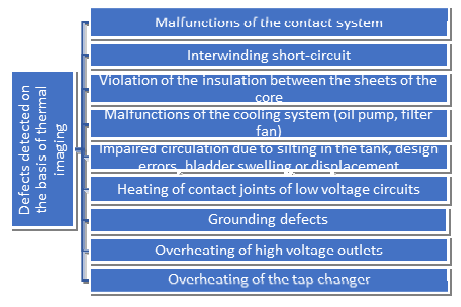

Simultaneously, the impact of the cooling system results in the circulation of oil, complicating the temperature distribution at the location of the fault. This, in turn, diminishes the accuracy of the assessment. In this regard, literature [5] indicates that when computer-assisted evaluation of the technical condition of power transformers is employed, various factors must be taken into account, including their design features, the type of cooling system and core, operational conditions, operational duration, manufacturing technology, and numerous other factors (Figure 2).

It should be noted that, for the evaluation of the effectiveness of the cooling system of transformers, two approaches should be employed as follows:

1. Assessment of the average temperature difference with respect to oil coolers operating under the same load and environmental conditions.

2. Comparison of the temperatures at the inlet and outlet pipes of the cooling system with factory specifications. These approaches are essential for a comprehensive evaluation of the performance of the transformer’s cooling system.

Experience shows that, in the first case, the average temperature difference should not exceed 2°C. If it does, it indicates that the cooling system is not functioning properly. In the second case, the temperature difference between the inlet and outlet pipes of the oil should not exceed 1-1.5°C.

It should be noted that power transformers are electromechanical systems, meaning that the distortion of their individual constructive elements and faults in their windings lead to the generation of electromagnetic phenomena [1]. Currently, there is no standardized vibration limit for assessing the technical condition of power transformers.

However, according to the results of research from various organizations, normally functioning transformers are characterized by the following parameters in terms of vibration [1].

- Vibroacceleration – 10 m/sec2

- Vibration speed – Below 10 mm/sec

- Vibration change – 100 µm

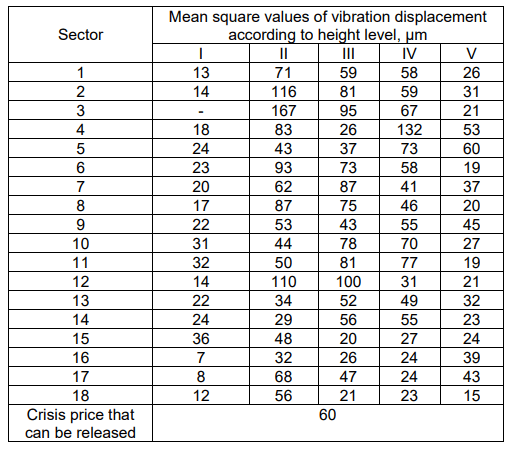

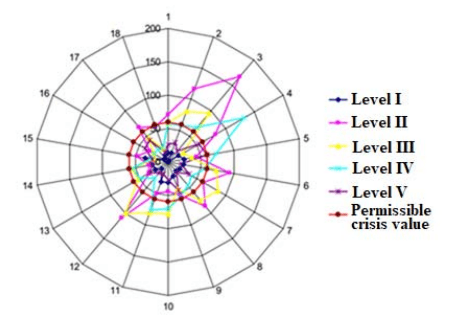

In modern times, the assessment of the technical condition of a transformer using a vibroanalyzer involves utilizing the root mean square value of vibration, and based on this, an amplitude spectrum is constructed concerning various sectors (levels) (Table 1, Figure 3).

Table 1. Vibration results obtained from measurement

The absence of a database and comparison tool for analyzing the results obtained in existing diagnostic methods sometimes leads to an increase in the loss of information.

One method for assessing the technical condition of power transformers and detecting various types of faults involves analyzing the oil extracted from the transformer core [2].

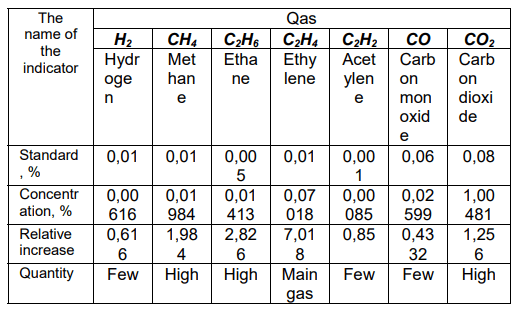

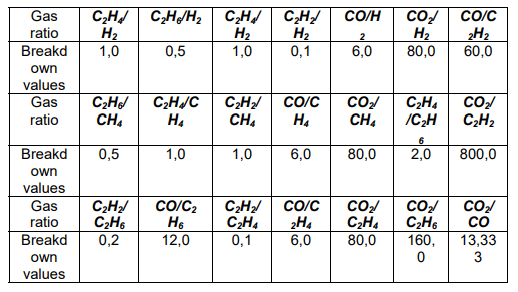

In this method, the results of physical-chemical analysis, such as the chromatographic analysis of gases dissolved in the oil, and the analysis of furans and other impurities, are utilized as initial data. The breakdown values of these results are presented in Table 2 and Table 3.

The chromatographic analysis of the extracted oil identifies two groups of faults:

1. Excessive heating of electrically conductive and constructive components.

2. Electric discharges in the transformer oil, allowing for specific identification.

The increase in temperature or the presence of void discharges in the oil in the first group causes changes in the concentrations and ratios of C2H4 – ethylene, C2H2 – acetylene, H2 – hydrogen, CH4 – methane, C2H6 – ethane gases (Table 3).

The second group of faults is attributed to electrical discharges in the transformer oil. They can be both small and large in magnitude.

In recent times, significant steps have been taken in the evaluation of the technical condition of electrical equipment used in the power system [7]. It is demonstrated that determining the location and measuring the level of partial discharges is one of the developing methods for diagnosing the technical condition of power transformers with oil cooling systems.

Table 2. The results of chromatographic analysis of the oil extracted from the transformer core and the breakdown values of the concentrations of dissolved gases

Table 3. Breakdown values of the concentrations ratios of dissolved gases in transformer oil

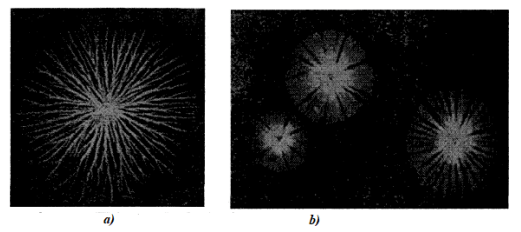

Partial discharges are a part of electrical discharges in the insulation gap and create local faults in transformers. These faults occur in places where the insulation is weakened due to the formation of gas in certain gaps or the presence of dense metallic cutting elements (Figure 4) [8,9].

Here, it is noted that due to the diversity of dielectric materials surrounding the gas and its entry point, the dielectric permeability varies. As a result, the dielectric field intensity in these areas is much higher compared to other locations. Therefore, partial discharges in localized zones can lead to the breakdown of insulation and, consequently, the rupture of the insulation gap, posing a significant danger. Literature [10, 11] also indicates that the following methods are available for identifying partial discharges:

1. Electrical method based on signal measurement.

2. Electromagnetic method based on the detection of partial discharges in the high-frequency range through electromagnetic emissions.

3. Optical method based on the detection of optical emissions during partial discharges.

4. Acoustic method based on the measurement of acoustic signals generated during partial discharges.

It is shown that these methods, based on the measurement of acoustic signals generated during partial discharges using contact and distance-type sensors, ensure operationality and high precision. These methods allow for the analysis of the technical condition of the transformer under stress and the timely localization of occurring damages.

One of the most widely used and effective methods for evaluating the technical condition of power transformers is the acoustic diagnostic method, which is based on the accurate determination and localization of the level of distributed sound discharges [12, 13].

Literature [14] indicates that diagnostic parameters used for evaluating the technical condition of power transformers without disassembly include:

– Temperature, – Pressure; – Leakage current value; – Sound level; – Vibration amplitude; – Vibropressure – Vibrovelocity

However, information about the reasons for changes in these parameters and their correlation with the residual operational life and reliability of the equipment is not provided here. The issues related to the problems mentioned are discussed in [15].

It should be noted that due to the specific design and purpose of power transformers, it is not possible to use diagnostic or monitoring systems designed for various technical systems here. Although these systems have several advantages, such as the diagnostic monitoring of the actual condition of the equipment under stress, high accuracy of input parameters, and the possibility of their retention, they also have the following conflicts:

1. They do not encompass the technical characteristics of transformers, diagnostic parameters, the mutual relationship, and dependence among these parameters. They only perform the monitoring of the observed equipment.

2. The input information consists of a set of data, and its analysis and processing present an additional challenge, requiring special mathematical tools and software for resolution.

3. The installation of a monitoring system in electrical stations and substations is expensive, and so on.

In the modern era, seamless control over the technical condition of power transformers, which are a crucial element of the power system, is considered one of the most pressing issues.

References [16-19] examine automated control systems for monitoring the technical condition of power transformers. The primary task of such systems is to seamlessly control the identification of potential faults at the initiation stage during the operational process. Systems such as TPAS (Transformer Performance Analysis System – USA), Siemens (Germany), and ABB Secheron (Switzerland) are widely applied. The TPAS system was developed at the Massachusetts Institute of Technology in the USA and is designed for the initial identification of the maximum number of faults in power transformers. This system determines the technical condition by detecting partial insulation breakdowns during the operation of power transformers, mechanical strength reduction due to short circuits, hotspots in the winding and magnetic system, regulation failure points under load, and damage to bushings and inputs. The TPAS system does not use generalized mathematical models based on the ModelBased Monitoring concept among individual faults of the transformer [19]. As shown in [19], Alstom Schorch Transforen applies the MS-2000 and MS-1000 types, and Siemens applies the Sitramt second-generation automated seamless control system based on the Sitatic calculation system appropriately for transformers with a power of 100 MVA and above, as well as transformers with a power ranging from 10 MVA to 100 MVA. These systems send an excitement message to the computation machine using special sensors. For example, the temperature of the hottest point is 150°C. That is, 150°C ˃ the standard [110°C], etc.

Research shows that complex diagnostic measures can occur and allow for the early detection of developing faults.

Complex diagnostic measures are based on normative documents, meaning:

1. Chromatographic analysis of oil is conducted once a year for power transformers with a voltage of 35-110 kV and twice a year for those with a voltage of 220 kV.

2. Inspection between repairs is performed once every 4 years.

3. Repair cycles include:

– Current repair every 2 years,

– Cooling system annually,

– Intermediate repair every 8 years,

– Capital repair cycle is not regulated

It is evident from here that identifying the damage to the cooling system at the initial stage using chromatographic analysis, which reveals faults originating from heat and electricity, is not possible. This indicates that the inability to accurately determine the precise mutual relationship between the causes of damage and the dynamics of developing faults identified through control and diagnostic systems, coupled with the frequent occurrence of uncertainties, leads to the emergence of unnecessary expenses. Therefore, the creation of a systematic control and diagnostic system that can eliminate the conflicts of existing systems should be considered as an important issue [20].

It should be noted that the speed of fault development depends on the influence of various operating modes and the characteristics of the network where individual feeders are connected. Therefore, control and diagnostic systems should also be capable of the following functions:

1. Optimal methods capable of identifying a large number of faults.

2. Early detection of faults to minimize repair costs.

3. Determining the location, type, and degree of development of the damaged element or unit.

4. Providing a grounded result for taking transformers out for repair.

[21,22] describe expert systems developed based on fuzzy logic and neural networks. A distinctive feature of expert systems based on neural networks is their self-learning system. The training of artificial neural networks, improving the quality, and determining the residual lifespan of transformers should continuously fill the knowledge base of this system through periodic evaluations.

Literature [22] indicates that in the fuzzy expert information system, the results of the chromatographic analysis of oil-soluble gases and thermal imaging device are entered into the database, and a set of fuzzy rules has been formulated for deriving logical conclusions between them. It is noted here that this expert system allows for the early detection of faults in electrical equipment during the initial development phase. Also, it is mentioned that in the future, this system can be used for diagnosing power transformers with a voltage level of up to 110 kV.

This indicates that power transformers, given their role in the management of the energy system, continue to be a regular subject of research worldwide [23].

Result

• Various diagnostic and monitoring systems prepared for different technical systems are used to evaluate the technical condition of power transformers.

• Mutual relationships and dependencies between informative parameters are not taken into account.

• The large number of informative parameters requires specialized mathematical tools and software.

• Existing systems provide an alarm signal for any fault, but they do not provide information about the cause and elimination of the fault.

• Uncertainties and errors in measurement systems are not considered.

• The characteristics of the network to which the research object is connected are not taken into account during the determination of the dynamics of fault development, etc.

REFERENCES

1. Гавриленко А.В., Долин, А.П., Методика вибрационного обследования силовых трансформаторов, 2004.

2. Б.В. Ванин, ЮН. Львов, М.Ю. Львов и др. О повреждениях силовых трансформаторов. // Электрические станции. — 2001.— № 9. – С. 53—58.

3. Л. Г. Сидельников, А. М. Седунин, А. Ю. Сыкулев, ООО «ТестСервис» Диагностика масла в силовых трансформаторах.

4. Л. Г. Сидельников, А. М. Седунин, А. Ю. Сыкулев, ООО «ТестСервис» Вибродиагностика и измерение частичных разрядов в силовом трансформаторе.

5. Ю.М. Голоднов Контроль за состоянием трансформаторов. – М.: Энергоатомиздат, 1988 – 88 с.: ил.

6. Михеев Г.М. Тепловизионный контроль высоковольтного оборудования: Учебн. пособие, Чебоксары: Изд-во Чуваш унта, 2004, 180 с.

7. Основные положения методики инфракрансой диагностики электрооборудования и ВЛ. / Под ред. С.А. Бажанова, М., 1999.181 с.

8. А.С. Карандаев, С. А. Евдокимов, О.И. Карандаева, С.Е. Мостовой, А.А. Чертоусов г. Магнитогорск, МГТУ. Kонтрольтехнического состояния силовых трансформаторов методом акустического диагностирования. Вестник ЮУрГУ, № 26, 2008.

9. International Standard «High-voltage test techniques-Partial discharge measurements» – IEC 60270, Third edition, 2000-12.

10. Применение технологии ЧР в диагностике изоляции / Claude Kane, Alexander Golubev. – http:/ http://www.partial-discharge, com.

11. О повреждениях силовых трансформаторов /Б.В. Ванин, ЮН.Львов, М.Ю. Львов и др. // Электрические станции. — 2001. —№ 9. – С. 53—58.

12. Львов, М.Ю. О надежности силовых трансформаторов и автотрансформаторов электрических сетей / М.Ю. Львов, Ю.Н.Львов, Ю.А. Дементьев // Электрические станции. – 2005. -№11.-С. 69-75.

13. Электрооборудование и электроустановки. Методы измерения характеристик частичных разрядов. -ГОСТ20074-83.

14. Аксенов, Ю.П. Использование усовершенствованных методов электромагнитной локации разрядных явлений для определения объема ремонта трансформаторов / Ю.П.Аксенов, В.И. Завидей, И.В. Ярошенко // Электро. – 2004. – №5.- С. 19-24.

15. Forsthoffer, M. Forsthoffer’s Component Condition Monitoring. 1st ed. Oxford, Butterworth-Heinemann, 2018, 204 p. ISBN

Authors: Ph.D. candidate. Tural Aliyev, Azerbaijan State Oil and Industry University, E-mail: aliyev.tural@asoiu.edu.az; Ph.D. candidate. Aydin Aliyev, Azerbaijan State Oil and Industry University, E-mail: aydin.aliyev@asoiu.edu.az.

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 100 NR 7/2024. doi:10.15199/48.2024.07.43