Published by Olena RUBANENKO1, Sree Lakshmi GUNDEBOMMU2, Iryna HUNKO3, Zdenek PEROUTKA1, Regional Innovational Center at the Faculty of Electrical Engineering University of West Bohemia (1), Plzen, Czech Republic CVR College of Engineering Mangalpalli (2), Hyderabad, India Vinnytsia National Technical University (3), Vinnytsia, Ukraine

Abstract. In this paper the analysis of online diagnostics of synchronous generations (SG) are presented. The main focus is done on different fault identification methods. The main causes for the failure of synchronous generators and the development of fault tree for different elements of synchronous generators are presented. Also presented the determination of the index of residual lifetime, for hydrogen cooled turbo generator of capacity 165 MW.

Streszczenie. W artykule przedstawiono stan wiedzy na temat różnych metod diagnostyki generatorów synchronicznych (SG). Szczególną uwagę zwraca się na metodologie identyfikacji awarii Przedstawiono główne awarie SG. W artykule stworzono drzewo błędów dla głównych elementów SG. Przedstawiono wyznaczenie wskaźnika resztkowej żywotności turbogeneratorów chłodzonych wodorem o mocy 165 MW. (Metody diagnostyki online generatorów synchronicznych)

Keywords: faults, diagnostics, electrical machine, reliability, artificial intelligence.

Słowa kluczowe: awarie, diagnostyka, maszyna elektryczna, niezawodność, sztuczna inteligencja

Introduction

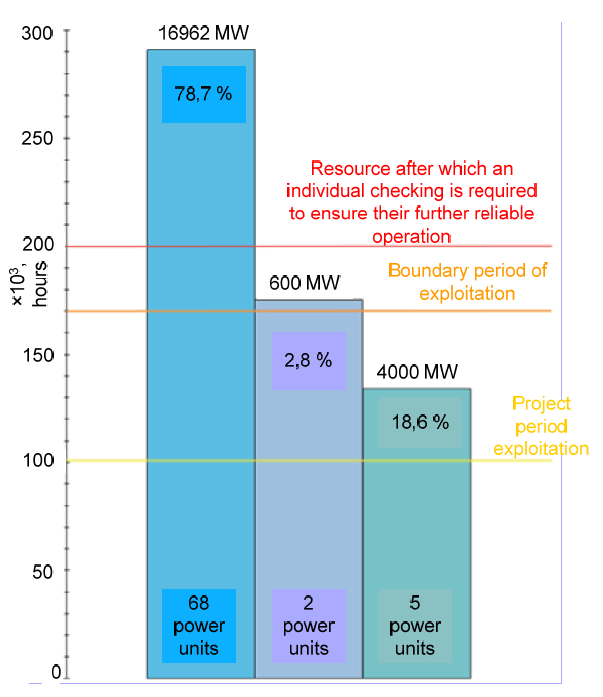

Synchronous Generators (SGs) are the fundamental components of most types of power plants. Their proper function is crucial for power delivery [1]. For example, in the report on the results of the activity of the National Commission for State Regulation of Energy and Utilities in Ukraine [2], in 2018, the technical condition of the energy sector infrastructure is approaching critical due to the high degree of equipment wear and tear, technology obsolescence, lack of sufficient investment, namely at most power plants, the design resource for the equipment has already been exhausted and is being used beyond the lifetime of the plant. For example, out of 75 generating units of thermal power plant companies, 68 units (16962 MW or 78.7%) are operated over the park lifetime, 2 units (600 MW or 2.8%) are operated over the term of operation and 5 units (4 000 MW, or 18.6%) is in excess of the design lifetime. Fig. 1 shows a diagram of the technical state of power units by the resource of work as of 01.01.2019, and, accordingly, the powerful synchronous generators of TPP (thermal power plants) [2, 3].

The early detection of SGs defects is essential. Timely diagnostics of SGs operating condition reduces the damage to power plants due to their extended failures. The forced outages and corresponding repairs are accompanied by economic damage, leading to fines, and reduced profits from the sale of electricity. For instance, in Texas, broken strands of stator bars on the end-winding could lead to massive faults for SGs, a problem that happened on a similar 750 MW SG unit one year ago. In the UK, the cooling water blockage of the SGs stator might cause a 500 MW SGs completed rewinding. In Belgium, errant shipping baffles led to overheating, which could result in fatal damages within a 500 MW SGs commissioning. These SGs all had experienced a similar phenomenon; they have been alerted of potentially serious failure by an SG’s condition monitoring system [4]. Accordingly, diagnostic tests and condition monitoring features of rotating machines, particularly synchronous generators, play a crucial role in power system and modern industries [5]. The predictive maintenance needs diagnostic solutions to identify when significant defects and non-desired conditions have happened, and when the maintenance is essential to prevent an in-service failure.

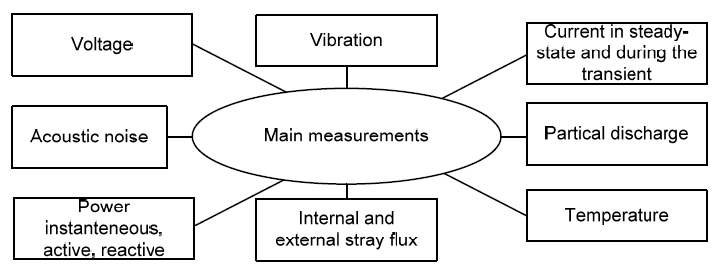

In the last decades, several off-line diagnostic testing methods and on-line monitoring approaches have been presented. These off-line and on-line methods have been implemented, particularly on important electrical machines. Different off-line diagnostic tests and on-line monitoring solutions, e.g. magnetic flux, partial discharge, temperature monitoring, and end winding vibration, have been improved effectively. However, some more modernized tests such as polarization/depolarization current, dielectric spectroscopy, and on-line leakage current monitoring have been developed. As explained, the off-line diagnostic tests and on-line monitoring systems of electrical machines, particularly SGs, have received a great deal of attention.

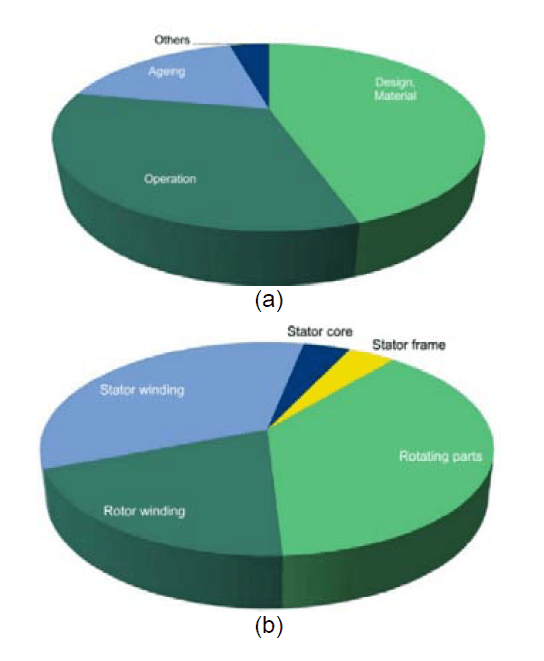

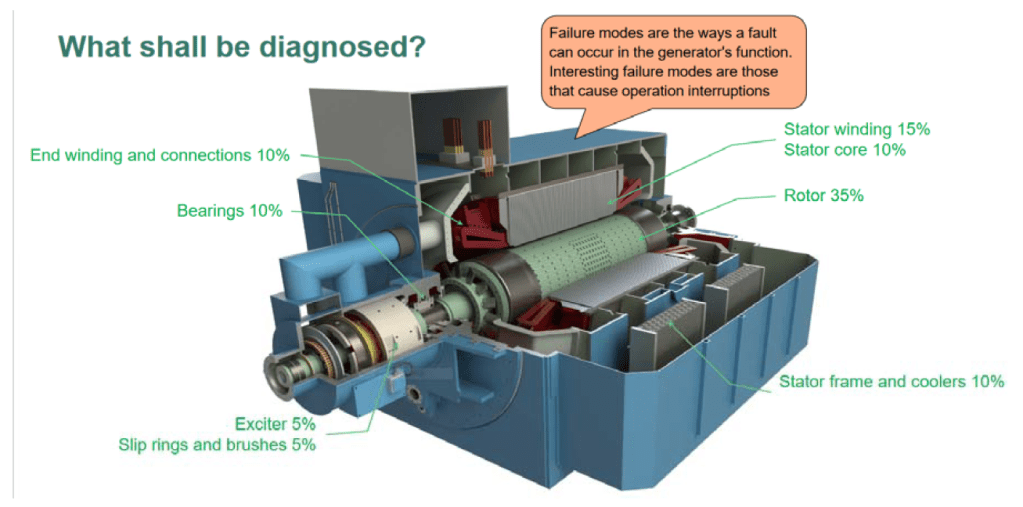

In Fig. 2 (b), the components of SGs that might fail and cause forced outages are shown [3]. The SGs failure modes are also presented in Fig. 3.

As revealed by Fig. 2 (b), the diagnostic tests and condition monitoring’s are useful for SG’s designers, manufacturers, operators, maintenance groups, and owners.

The first result that claims attention from Fig. 3 is that the stator and rotor windings (electrical parts) are the most important parts, which could experience failures and lead to a forced outage of SGs. In [6] shown of the stator windings fault can be 21-40 %.

But all faults depend on type synchronous generators and place, where are operated. Investigated different types of four turbogenerators TPP and HPP (hydroelectric power plants): generator (SG) of HPP 117 MW, manufacturers, operators, maintenance groups, and owners.

Hydrogen-cooled synchronous turbogenerator (HCST) 300 MW; Hydrogen-water-cooled synchronous turbogenerator (HWCST) 165 MW; Hydrogen-cooled synchronous turbogenerator (HCST) 100 MW; Synchronous The first result that claims attention from Fig. 3 is that the stator and rotor windings (electrical parts) are the most important parts, which could experience failures and lead to a forced outage of SGs. In [6] shown of the stator windings fault can be 21-40 %. But all faults depend on type synchronous generators and place, where are operated. Investigated different types of four turbogenerators TPP and HPP (hydroelectric power plants):

Hydrogen-cooled synchronous turbogenerator (HCST) 300 MW; Hydrogen-water-cooled synchronous turbogenerator (HWCST) 165 MW; Hydrogen-cooled synchronous turbogenerator (HCST) 100 MW; Synchronous generator (SG) of HPP 117 MW.

The major players in the field

The interesting solutions for online SG diagnostics have been presented by e.g. ABB [7], Siemens, Fortum, Kinectrics, EthosEnergy, Entegro, Elektromotors. Fortum offers, PD monitoring of the stator winding; rotor flux monitoring; monitoring stator winding and cooling air temperatures; monitoring bearing vibration; operating parameter trends; generator protection relays and oth. But have some problem, because online diagnostics can: identify 5% failure modes and detect an additional 35% [3]. Siemens has a fine solution: GenAdvisor monitoring and diagnosis system, that allows PD, inter-turn short circuits in the rotor, vibrations in the stator end windings, voltages in the rotor forging as well as currents via the shaft grounding brushes [8] (Fig. 4).

Different diagnostic tests and measurements have been introduced for SGs. The most important methods, which have been practically used in industrial plants, are as follows: Fig. 3. SG’s failure modes [3] Different diagnostic tests and measurements have been introduced for SGs. The most important methods, which have been practically used in industrial plants, are as follows:

– temperature monitoring system;

– end winding vibration monitoring [9];

– partial discharge measurements [10];

– rotor inter-turn short circuit measurement [11, 12];

– shaft voltage and shaft grounding current monitoring [13];

– digital torsion monitoring [14];

– frequency response analysis (FRA) [15, 16].

Several technical barriers adversely affect the diagnostic tests and condition monitoring systems, as follows [17, 18]:

– Uncertainty of the complete set of measures for assessing the SG’s condition;

– it is not possible to define an integral criterion for all failures;

– different factors affect the decision-making about the SG’s defects and failures;

– some factors just have a quantitative expression;

– the complex relationship among influencing factors;

– the difficulty of mathematical modeling for crucial factors and their interconnections;

– lack of information about the parameters and the influencing factors;

– the dependency of the diagnosis and decision-making system on the experiences, qualifications, and intuition of staff.

These features limit the capabilities of conventional diagnostics and condition monitoring systems. Hence, the expert systems (ESs) are deployed for developing an efficient condition monitoring system. The heuristic algorithms using historical data, technical measurements, and questioner-based data collection of academic and industrial experts facilitate the well-organized condition monitoring solutions [19-21].

Firstly, it is necessary to create a database of SG’s faults and abnormal conditions and their main reasons. Although different models have been introduced about SG’s faults and defects, a comprehensive model that categorized all failures and corresponding reasons have not been developed. In the second step, we use Fuzzy-AHP (analytic hierarchy process) technique to set a database of SG’s failures and their reasons.

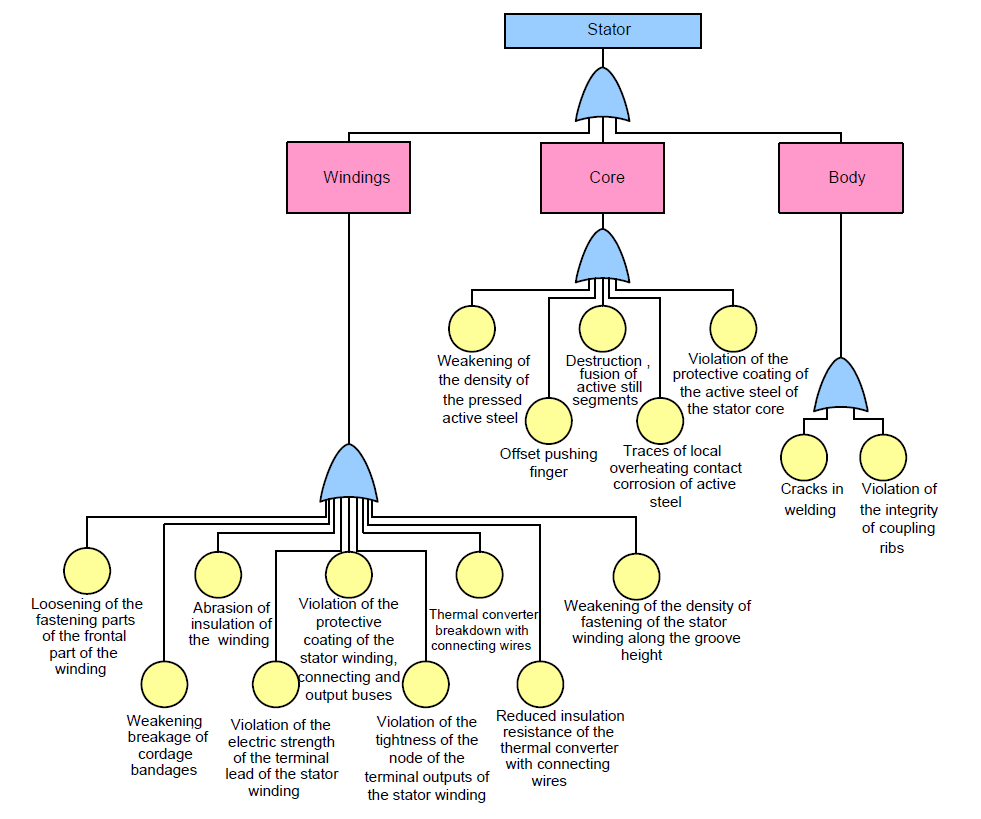

Moreover, to assess the validation of our identified failures, failures’ reasons, and diagnostic tests, carried out several laboratory experimental tests, site visits, and frequently communicated with the industrial experts and academic specialists. It should be noted that the AHP methods have been deployed in other technical studies and knowledge management projects, while in the field of SGs have not been utilized effectively. This study benefits from Fuzzy-AHP techniques’ advantages. The Fuzzy-AHP technique has been employed, which is more efficient in comparison to its conventional non-fuzzy version. Because it could better handle the uncertainties as well as obscure judgments in multi-criteria decision making (MCDM) problems. Afterward, based on the developed Fuzzy-AHP model, the fault tree of each sub-system is produced. For instance, the typical fault tree for the stator of SGs is shown in Table 1 and Fig. 5. The main contribution here can be the creation of a universal database about faults and FTA that can adapt for the operational conditions. The main approach for creating FTA is well described in the International standard IEC 61025.

Determination of the residual lifetime of the synchronous generator

External inspection (the first level of assessment of the technical condition of the SG) provides a simplified assessment. It allows to detect: noise, vibration, high temperature and other defects.

Table 1. List of reasons for stator failures of a typical SG

At the second level, the technical condition of not only the external elements of the SG, but also the internal elements (for example, the amplitude frequency response of the stator windings), as well as by determining the technical condition of the SG in the scope of maintenance tests. At this level, the main goal is a determination more accurately technical condition than at the first level. Also assess the physical wear of SG to justify the possibility of further operation, as well as repairing of internal defects, at the initial stage of their development, prediction of an emergency situation. To increase the efficiency of the operation of the diagnostic system is proposed usage ANN (artificial neural networks) and expert system. Expert systems, based on the structured knowledge-rules recorded in the database, provide the necessary information support, based on the experience of highly qualified experts and the necessary data from the database.

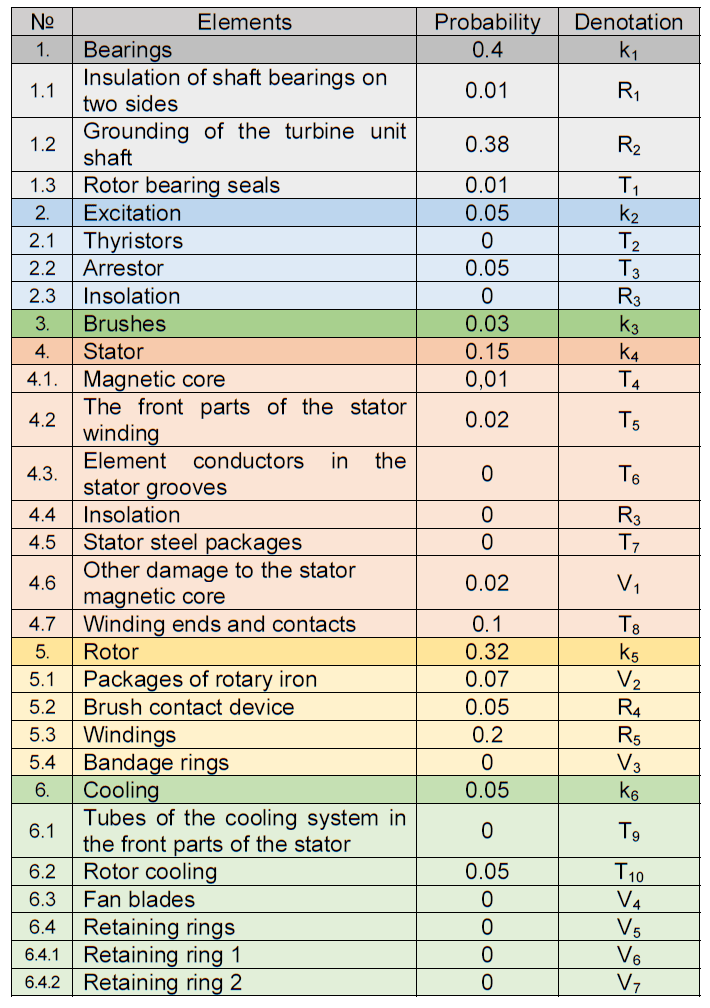

Currently existing SG diagnostic systems use well-known mathematical SG models in their calculations, but these models have a significant drawback – they cannot identify and account for functional relationships between many of the monitored diagnostic parameters simultaneously in a single mathematical model in real-time. The task is complicated by the incompleteness of the initial data, when some of the parameters are not known at the time of calculation, for example, due to the need for additional research on disconnected SG, and SG at this time it is desirable not to disable. ANN is a very constructive technology for establishing such connections. For example, showed assess technical condition for hydrogen-cooled turbo generator capacity 165 MW. This SG is used on a thermal electric station. Firstly, created a table 1 with collected all data – the main reason for failure in this SG and probability occurrence. This data is statistic data for all time operation by taking into account expert minds and normative documents.

In Table 2, under the controlled diagnostic parameter is the parameter, the deviation of which from the normative value contributed to the removal of SG for repair, or was taken into account when removing SG for repair. As diagnostic parameters in Table 2 are: parameters that characterize the condition of the elements SG.

In Table 2 and in Fig. 6 shows: k1-k6 – residual lifetime indexes: bearings, excitation systems, brushes, stator, rotor, cooling system; R1-R6 – resistance of insulation grounding, contact winding, T1-T9 – the temperature of the magnetic circuit, contacts, arrester, stator steel; V1-V7– vibration.

After analyzing the data in Table 1 and literature sources, a diagram is created that shows the dependent or independent influence of diagnostic parameters on the coefficient of the total residual TG lifetime (Fig. 6).

Table 2. Reasons to removal for repair SG and probability occurrence

In Fig. 3 shows the percentage of detected failed elements, which is given as a percentage of the total amount of failed elements. In Fig. 6 marked the blocks of elements of SG, for that deviation their parameters from normative value to be reasons to removal for repair SG. In order to obtain a total index of the residual lifetime, which is determined by taking into account the values of all diagnostic parameters and their impacts, it is proposed to move from the known values of diagnostic parameters of main elements od SG to the corresponding values of a index of residual lifetime for each diagnostic parameter. These indexes are determined in nondimensional units and characterize the total operating time of the SG from the moment of control of its technical condition to the transition to the limit condition, when the diagnostic parameter reaches the limit value of residual technical lifetime.

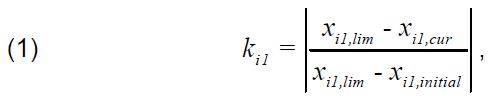

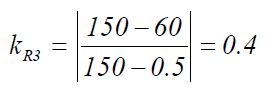

The coefficient of residual resource ki on the i-th diagnostic parameters:

where xi1,lim is the limit normative value of the i1th diagnostic parameter; хі1,cur is the value of the i1th diagnostic parameter at the time of control; хі1,initial is the initial value of the i1th diagnostic parameter (at the time of commissioning of new equipment or after repair ); i1 is diagnostic parameter.

Thus, for hydrogen-cooled turbo generator capacity 165 MW, the insulation resistance of the stator winding R3 – after repair was 150 MΩ, and at the time of diagnosis was 60 MΩ, the limit value of this parameter is 0.5 MΩ. Therefore, the index of residual lifetime kR3 for the diagnostic parameter R3 is determined by expression (1):

For the serial part of the block diagram, the coefficient of the total residual lifetime is defined:

where kτ is the coefficient of the residual SG lifetime for the i-th diagnostic parameter, τ is the τth diagnostic parameter, v is the number of blocks in the serial part of the block diagram, pτ is the probability of deviations of the controlled parameter from the maximum allowable normative value of this parameter:

where yτ is the number of deviations of the controlled parameter from the maximum allowable normative value of this parameter, which were detected by controlling the τth diagnostic parameter from the total number of detected deviations of controlled parameters from the maximum allowable normative value, m is the total number of detected deviations of controlled diagnostic parameters maximum allowable normative values. Therefore, the coefficient of the total residual lifetime SG is determined by the expression:

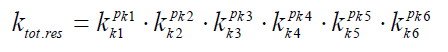

where kk1, kk2, kk3, kk4, kk5, kk6 – known at the time of calculation of the values of the indexes of the residual lifetime, respectively, on the parameters k1, k2, k3, k4, k5, k6; рk1, рk2, рk3, рk4, рk5, рk6 – probabilities of deviations of values of diagnostic parameters from maximum admissible normative values taking into account the total number of deviations of all diagnostic parameters, according to Table1: pk1 = 0.4; pk2 = 0.05; pk3 = 0.03; pk4 = 0.15; pk5 = 0.32; pk6 = 0.05.

Then, for a case when k1 = k2 = k3 = k4 = k5 = k6 = 1, ktot.res = 1, at k1 = k2 = k3 = k4 = k5 = k6 = 0.5; ktot.res = 0.5 and at k1 = k2 = k3 = k4 = k5 = k6 = 0, ktot.res = 0.

To create a mathematical model of the index of the residual lifetime SG was used parameters, that can be concluded about the condition of SG. But none of these parameters fully characterizes the technical condition of the SG, it only indicates certain changes in the technical condition of the SG. If one of these technical parameters goes beyond the normative limits, it does not mean that the SG has completely lost its efficiency. Therefore, the task is to find not always known, fuzzy interactions of different technical parameters on the general technical condition of SG and the most accurate prediction of the dynamics of damage and their impact on the general technical condition.

ANN allows us to take into account the values of different diagnostic parameters when diagnosing SG and create a basis for the rules of their interaction. Created a mathematical model of the residual resource index, which can obtain the analytical dependence of the residual SG lifetime index on diagnostic parameters in the form of a polynomial.

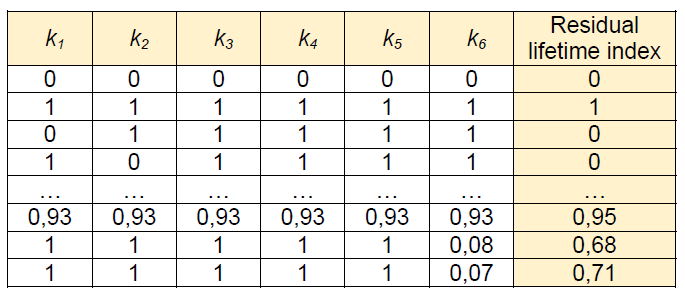

The formation of initial training data was carried out as follows. For the six input parameters of the model, which changed from 0 to 1, the index of the total residual lifetime was determined. For the convenience of data application and simplification of current calculations in the MATLAB the input parameters of the model were reduced to relative units of their deviation from the norm.

The six input parameters of the model are the coefficients of the residual SG lifetime, which correspond to the six diagnostic parameters. The number of parameters can be larger.

Table 3. The parameters of the sensor List of reasons for stator failures of a typical SG

Table 4. The fragment of values of residual lifetime SG index corrected by experts

A fragment of the calculation results is given in table III. The complete table contains 1212 considered variants of combinations of diagnostic parameters and the corresponding values of the total residual SG lifetime. Next, in 63 rows of this table, the value of the residual SG resource index was adjusted by interviewing experts: qualified representatives of the SG repair shop of the TPP and usage statistic information about the failure in this type SG. The corrected data were used as training data in modeling in the computer mathematics system MATLAB The Fuzzy Logic Toolbox was used for this purpose. Using the ANFIS Editor (Edit, Adaptive Network of Fuzzy Inference of the System) using a hybrid learning algorithm and using the Sugeno fuzzy inference algorithm, a neuro-fuzzy model of the residual lifetime index was obtained.

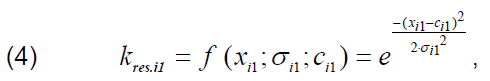

For each input variable of the neuro-model, four linguistic terms with Gaussian membership functions were used, expression (4):

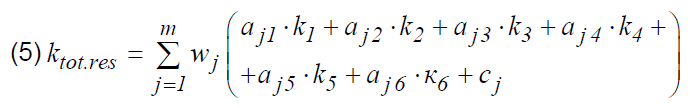

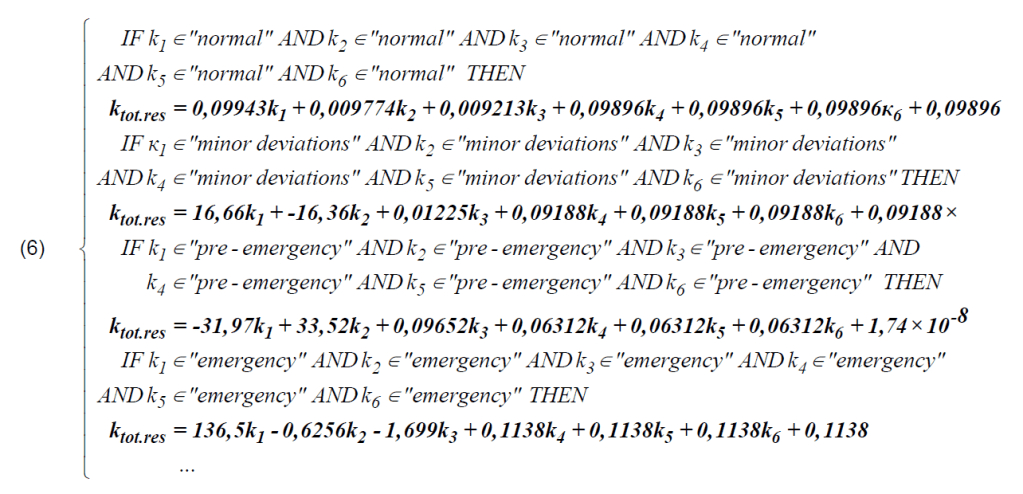

where σ2i1 are numerical parameters, in probability theory it is called the dispersion, ci1 is the mathematical expectation, i1 is the input parameter of the model, which corresponds to the diagnostic parameter, and xi1 is the value of i1 input parameter of the model: x1 = k1, x2 = k2, x3 = k3, x4 = k4, x5 = k5, x6 = k6. These are such terms as “normal” values of the diagnostic parameter, “minor deviations” of the value of the diagnostic parameter, “pre-emergency” values of the diagnostic parameter, “emergency” values of the diagnostic parameter. To find the value of the coefficient of the total residual resource we use a fuzzy nonlinear autoregressive model of the coefficient of the total residual resource SG. This model establishes a fuzzy nonlinear transformation between the values of the residual lifetime index for diagnostic parameters and the total index of the residual lifetime: ktot.res = F(k1, k2, k3, k4, k5, k6), where F is a fuzzy functional transformation. The output of the model ktot.res is found as a balanced sum of conclusions of the base of rules written in the form of a system of logical equations.

where 0 ≤ wj ≤ 1 – the degree of implementation (weight) of the j rule, which is determined by the correspondence of the actual changes in the diagnostic parameters of SG, which are reflected in the j rule. The setting of the model is to determine the parameters of membership functions and output equations. The terms of the values of linguistic variables are given in the form of Gaussian membership functions. It is necessary to determine the standard deviation and mathematical expectation of Gaussian membership functions, the parameters of the equations of inference (a11 – a44, c1 –c4). Results of calculation presented in exspression (6).

Conclusion

This paper introduces an approach of a life-time estimation of synchronous generators considering corrective actions. The proposed technique consists of the following stages: creating a database of SG’s faults; building FTA, determination of the residual lifetime of the synchronous generator with the use of ANN. This method was used for the determination of expression for calculation of residual resource hydrogen-cooled turbo generator capacity 165 MW.

There is a research gap about providing a comprehensive scheme for condition monitoring of SGs. In practice, the existing on-line methods could only identify 5% of defects, while 45% of potential failures could not be detected. Therefore need to find new techniques and theories that are searched for the cooperation of different kinds of SGs’ diagnostic models. Need to fill such a knowledge gap by developing a comprehensive method that can detect more potential failures and abnormal behaviors. The proposed approach and diagnostic solutions can decide on this task.

REFERENCES

[1] C. P. Salomon et al., A Study of Fault Diagnosis Based on Electrical Signature Analysis for Synchronous Generators Predictive Maintenance in Bulk Electric Systems, Energies, 12 (2019), nr 58, 1-16

[2] Report on the results of the activities of the National Commission for State Regulation in Energy and Utilities in 2018.NERCEP Resolution No. 440, 29.03.2019.26

[3] G. Csaba, Generator diagnostics from failure modes to risk for forced outage [Online]. Available: https://irispower.com/wpcontent/uploads/2018/06/

[4] Available: https://eone.com/hydrogen-systems/technicalreprints/condition-monitoring-turbine

[5] T. Wang, G. Lu, and P. Yan, A Novel Statistical Time-Frequency Analysis for Rotating Machine Condition Monitoring, IEEE Transactions on Industrial lectronics, 67 (2020), no. 1, pp.531-541.

[6] L. Frosini, Monitoring and Diagnostics of Electrical Machines and Drives: a State of the Art in 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), 1 (2019),169-176.

[7] REG 670 – Generator protection. Available: https://new.abb.com/substation-utomation/products/protectioncontrol/generator-protection/reg670

[8] GenAdvisor monitoring and diagnosis system for turbogenerators. Available: https://assets.new.siemens.co

[9] Y. Shan, J. Zhou, W. Jiang, J. Liu, Y. Xu, and Y. Zhao, Vibration Tendency Prediction of Hydroelectric Generator Unit Based on Fast Ensemble Empirical Mode Decomposition and Kernel Extreme Learning Machine with Parameters Optimization, 11th International Symposium on Computational Intelligence and Design (ISCID), 2 (2018), 287-290.

[10] K. Tanaka, H. Kojima, M. Onoda, and K. Suzuki, “Prediction of residual breakdown electrical field strength of epoxy-mica paper insulation systems for the stator winding of large generators,” IEEE Transactions on Dielectrics and Electrical Insulation, vol. 22 (2015), no. 2, 1118-1123

[11] J. Li, W. Shi, and Q. Li, Research on interturn short circuit fault location of rotor winding in synchronous electric machines, 20th International Conference on Electrical Machines and Systems (ICEMS), 2017, . 1-4.

[12] W. Shuting, L. Yonggang, L. Heming, and T. Guiji, A Compositive Diagnosis Method on Turbine-Generator Rotor Winding Inter-turn Short Circuit Fault, IEEE International Symposium on Industrial Electronics, 3 (2006), 1662-1666.

[13] P. I. Nippes, “Early warning of developing problems in rotating Machinery as provided by monitoring shaft Voltages and grounding currents,” IEEE Transactions on Energy Conversion, 19 (2004), no. 2, pp. 340-345.

[14] Y. Zhihe, H. Xuhuai, and C. Guang, Research of torsional vibration monitoring platform for turbine generator, IEEE International Conference on Computer Science and Automation Engineering (CSAE), 3 (2012), 577-580.

[15] S. Uhrig, F. Öttl, N. Augeneder, and R. Hinterholzer, “Reliable Diagnostics on Rotating Machines Using FRA,” in Proceedings of the 21st International Symposium on High Voltage Engineering, Cham, (2020), 738-751.

[16] O. Rubanenko, M. Grishchuk, and O. Rubanenko, “Planning of the experiment for the defining of the technical state of the transformer by using amplitude-frequency characteristic,” Przeglad Elektrotechniczny, 96 (2020), nr 3, 119-124.

[17] Z. Gao, C. Cecati, and S. X. Ding, A Survey of Fault Diagnosis and Fault-Tolerant Techniques – Part I: Fault Diagnosis With Model-Based and Signal-Based Approaches, IEEE Transactions on Industrial Electronics, vol. 62 (2015), no. 6, 3757-3767.

[18] Z. Gao, C. Cecati, and S. X. Ding, A Survey of Fault Diagnosis and Fault-Tolerant Techniques – Part II: Fault Diagnosis With Knowledge-Based and Hybrid/Active Approaches, IEEE Transactions on Industrial Electronics, 62 (2015), no. 6, 3768-3774.

[19] R. Gogulaanand, T. Balasubramaniyavijayan, R. Arunsivaram, S. Aishwarya, P. V. S. Nag, and C. S. Kumar, Intelligent monitoring of Synchronous Generators in Smart Grids using Deep Neural Network, 3rd International Conference on Trends in Electronics and Informatics (ICOEI), (2019), 1376-1379.

[20] R. Gopinath, C. Santhosh Kumar, K. I. Ramachandran, V. Upendranath, and P. V. R. Sai Kiran, Intelligent fault diagnosis of synchronous generators, Expert Systems with Applications, 45 (2006), 142-149,

[21] J. Zhang, W. Ma, J. Lin, L. Ma, and X. Jia, “Fault diagnosis approach for rotating machinery based on dynamic model and computational intelligence,” Measurement, 59 (2015), pp. 73-87.

[22]O. Rubanenko, O. Kazmiruk, V. Bandura, V. Matvijchuk, and O. Rubanenko, “Determination of optimal transformation ratios of power system transformers in conditions of incomplete information regarding the values of diagnostic parameters,” Eastern-European Journal of Enterprise Technologies, Article vol. 4, (2017) no. 3-88, 66-79.

[23]P. D. Lezhniuk, O. V. Nikitorovich, and O. E. Rubanenko, “The operative diagnosticating of high-voltage equipment is in the tasks of optimum management the modes of the electroenergy systems,” Technical Electrodynamics, (2012) no. 3, 35-36.

Authors: Olena Rubanenko, Doc., PhD., Regional Innovational Center at the Faculty of Electrical Engineering University of West Bohemia, Plzen, Czech Republic, rubanenk@rice.zcu.cz; olenarubanenko@ukr.net Sree Lakshmi Gundebommu, Prof., PhD., CVR College of Engineering Mangalpalli, Hyderabad, India, s_sreelakshmi@yahoo.com Iryna Hunko, PhD. Department of Electric Stations and Systems, Vinnytsia National Technical University, Khmelnytsky highway 95, 21021, Vinnytsya, Ukraine iryna_hunko@ukr.net; Zdenek Peroutka, Prof., PhD., Dean with the Faculty of Electrical Engineering, Head of the team of Regional Innovational Center University of West Bohemia, pero@kev.zcu.cz

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 97 NR 4/2021. doi:10.15199/48.2021.04.04