Published by Andrzej Ł. Chojnacki, Kielce University of Technology, Department of Power Engineering

ORCID: 0000-0002-9227-7538

Abstract. The article presents the influence of weather conditions, represented by the ambient temperature, for the intensity of the failure of MV overhead power lines. It presents the mechanisms of damaging the equipment by the high and low temperatures. It shows the method of determining the intensity of failure of power facilities as a function of ambient temperature. The article presents the empirical results obtained for the MV overhead power lines exploited in the Polish electricity grids.

Streszczenie. W artykule przedstawiono wpływ warunków atmosferycznych reprezentowanych przez temperaturę otoczenia na intensywność uszkodzeń napowietrznych linii elektroenergetycznych SN. Zaprezentowano w nim mechanizm uszkadzania tych urządzeń na skutek oddziaływania wysokich oraz niskich temperatur. Omówiono metodę modelowania zależności intensywności awarii obiektów energetycznych od temperatury otoczenia. Zaprezentowano wyniki uzyskane podczas wieloletnich badań dla napowietrznych linii elektroenergetycznych SN eksploatowanych w polskich sieciach dystrybucyjnych energii elektrycznej. (Wpływ temperatury otoczenia na intensywność awarii napowietrznych linii elektroenergetycznych średniego napięcia)

Słowa kluczowe: temperatura otoczenia, intensywność awarii, linie dystrybucyjne, niezawodność systemu elektroenergetycznego

Keywords: ambient temperature, failure intensity, power distribution lines, power system reliability

Introduction

A contemporary recipient of electricity sets very high requirements concerning the quality and continuity of electricity supply. The systematically increasing unit power rating of power stations and lines increases the danger of shutdown of higher power values in the case of their failure, thus leading to increasing limitations in electricity supply for the recipients. This causes substantial material losses and in extreme cases can result in health or life hazards. In order to avoid the aforementioned hazards, design engineers must know the principles applicable to power device reliability and aim at optimally selecting the device parameters, thereby ensuring reliable operation. The timeliness of the aforementioned aspects and the need to conduct further research in the scope of the reliability of power structures are confirmed, among others, by numerous publications on the subject matter [9, 13, 16].

According to the definition presented in [12, 14], reliability is the ability of elements (structures) to perform the set functions in specific conditions and in a determined time period, with simultaneous adherence to acceptable parameters. Usually, “specific conditions” are adopted as fixed, and reliability is considered only in the operation time function. Meanwhile, it is necessary to note that time does not directly affect the reliability of structures. Any changes in the ability of elements to perform the set functions are an effect of internal and external (environmental) exposure. Exposure changes in time and the changes are usually random.

The impact of the environment on the behaviour of structures has been known for a long time. Many years before the development of reliability theory, standardisation acts on environmental studies were established, aimed at checking whether the structure is able to perform its task if the specified environmental exposure will affect the structure with specific intensity and for a specific time period. When designing structure reliability, two components are often taken into consideration: temperature impact and total impact of other environmental exposure [10, 12]. Unfortunately, the literature features a relatively low number of up-to-date elaborations on the topic. It is more often possible to find publications concerning the impact of weather on the variation of electrical loads, e.g. [1].

Impact of ambient temperature on the reliability of power engineering structures

When analysing the impact of ambient temperature on the reliability of power engineering structures, it is necessary to take into consideration three principal aspects

• impact of high temperature;

• impact of low temperature;

• impact of quick changes in temperature

The maximum air temperature in the shade, in open areas, does not exceed 60o C on the ground, but the surface temperature of devices located in open areas, without covers, can exceed 100oC. Such temperatures have a negative impact on the operation of particular structures and their components. High temperature can be the cause of considerable damage, because it degrades material properties by causing their softening, melting, sublimation, evaporation, reduction in viscosity, changes in sizes and thermal ageing [3, 10, 15, 18]. High temperature can cause mechanical deformations resulting from the expandability of materials. They are especially strong in the case of combining materials with various expandability factors or uneven heating of parts of a single material, but with substantial sizes. Mechanical deformation can in turn be the cause of mechanical damage or changes in products’ electrical parameters [10]. On the other hand, the softening and melting of plastic materials leads to structural weakening or damage, and to resin fill leaks. Accelerated thermal ageing of organic insulation materials manifests itself with the migration of softeners and their evaporation from thermoplastic materials. On the other hand, thermosetting materials lose their volatiles and become delaminated. Material ageing can also cause changes in their electrical properties, namely [4, 10, 15]:

• reduction in the electrical cross-resistivity and surface resistivity of dielectrics;

• reduction in the voltage resilience of dielectrics;

• changes in the dielectric constant of dielectrics (the character of changes and their magnitude vary for different materials);

• increase in dielectric loss;

• increase in the electrical resistivity of metals.

The structural resistance to high temperature impact can be verified in laboratory conditions by conducting a dry heat test according to the IEC 60068-2-2:2007 standard [7].

Negative air temperatures can also have a negative impact on power devices, especially because the air temperature of devices placed in the open air can reach values significantly below the ambient temperature as a result of heat radiation. Negative temperatures mainly contribute to the degradation of the mechanical properties of power devices and structures. They cause an increase in the fragility of materials, increase in viscosity and solidification of liquids, reduction in mechanical durability and shrinking of materials. Changes in the linear size cause mechanical damage by the jamming and seizure of co-operating movable components. Material shrinkage can also contribute to the weakening of joints and part breakage or cracking. As result of frosting and icing, the product’s weight increases, which can also cause damage. Plastics usually become hardened and more fragile in negative temperatures. Changes in the dimensions and hardness of washers and gaskets can cause the unsealing of products. Solders with high tin content become fragmented and crushed under weak impact. Increases in the viscosity of lubricants and oils hinder the operation of movable components, and their damage in the case of lubricant freezing [10].

Negative temperatures also lead to changes in the electrical parameters of materials, such as electrical conductivity, dielectric loss, dielectric constant and magnetic permeability, thereby causing changes in the parameters of electrical elements and devices, whereas these are usually beneficial changes (reduction in the dielectric loss factor of many insulating materials, increase in insulation’s electrical durability and resistivity, along with a reduction in temperature) [10].

The structural resistance to negative temperature can be verified in laboratory conditions by conducting a cold test according to the IEC 60068-2-1:2007 standard [5].

Changes in temperature result from daily changes in air temperature, varying insolation, sudden wetting of the device, etc. Daily temperature changes are substantially smaller at the seaside than deep inland. Sudden temperature changes affect power devices and structures subjected to the direct impact of solar radiation. Their surface can reach temperatures exceeding 100oC, after which they become wetted by rain with a substantially lower temperature (the temperature of hailstorms can reach approx. 0oC). In this case, the surface temperature can change rapidly by approx. 100oC [10, 15].

Changes in temperature can cause dangerous mechanical stress in the material and cause changes in electrical parameters. Fast expansion and shrinking of materials leads to the weakening of connections and to cracks and breakage. In the case of sealed devices, they can become unsealed. A common phenomenon is the cracking of protective covers as a result of the variable expandability of the base and protective layer’s material. The effects of fast temperature changes are similar to those caused by positive and negative temperatures. The difference is that high intensity of temperature changes causes more complete damage, whereas positive or negative temperatures cause parameter damage (partial, incomplete) far more often [10, 15].

Structural resistance to the impact of temperature changes can be verified in laboratory conditions by conducting the tests specified in the IEC 60068-2-14:2009 [6] and IEC 60068-2-33:2002 [8] standards.

Seasonality and causes of damage to overhead mv power lines

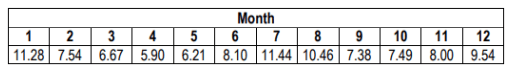

Table 1 presents the frequency of damage to overhead MV power lines with distribution to particular months. Data in the form of histograms and approximate functions are presented in figure 1.

Table 1. Frequency of overhead MV line failures in particular months of the year [%]

Most failures of overhead MV lines were observed in the summer (July, August) and in winter (December, January). The summer featured 427 failures, which constitute 21.90% of all damage. The winter featured 406 failures, which constitute 20.82% of all damage. In other months, the lines’ unreliability is below the average damage intensity. This allows for the general statement that extreme temperatures occurring in the winter and summer periods greatly affect the failure intensity in power devices.

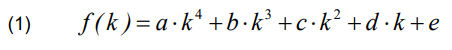

Any mathematical functions can be the approximate function. Due to the transparency and simplicity of the transcript, a multinomial was adopted as the approximate function. Due to the fact that the approximate function factors obtained for an order higher than fourth are close to zero, a decision was made to approximate the function of seasonal variability of line failure frequency with a multinomial of at least the fourth-order. The multinomial has the following form:

where: k – subsequent month number; a, b, c, d, e – approximate function factor.

The approximate function factors of the seasonal variability in the overhead MV line failure frequency presented in figure 1 amount to: a = 0.0137; b = -0.3832; c = 3.6405; d = -13.1109; e = 21.5470. The correlation factor of the designated function in relation to empirical data amounts to r = 0.85.

The percentage share of the causes of line failure with consideration of seasonality is included in table 2. The percentage share of particular causes of line failure in the total number of failures is presented in figure 2.

The most serious cause for overhead MV line failures is the ageing process, which contributes to approx. 19.38% of all line damage. The second cause concerns trees and branches, which resulted in approx. 16.31% of all damage. Seasonal causes that greatly contribute to the failure rate of overhead MV lines are electrical discharges as well as icing and frosting. They caused, respectively, 13.64% and 9.23% of all damage.

Table 2. Causes of overhead MV line failures in particular months [%]

Table 3. Length of overhead MV power lines in subsequent observation years [km]

Analysis of the impact of ambient temperature on the failure intensity in overhead mv power lines

The average intensity of power line damage, with the assumption of immobility and ergodicity of the damage and restoration processes, can be determined with the following dependency [2, 11, 17]:

where: m – observed number of failures in a time interval Δt; np – sample size at the beginning of the observation period; nk – sample size at the end of the observation period; Δt – total observation time.

In order to designate the intensity’s temperature characteristics ¯λ = f(t) it is necessary designate the value ¯λ(Ti) for subsequent temperature ranges Ti. For this purpose, the dependency (2) takes into consideration the number of failures m(Ti) that occurred in a specific temperature range i and the duration of the temperature range Δt(Ti):

where: m(Ti) – number of failures in the time interval Δt(Ti); Δt(Ti) – time of occurrence of temperature Ti in the considered time period Δt; 𝜏(Ti) – relative time of occurrence of temperature Ti in the considered time period Δt:

When designating the value ¯λ(Ti) for subsequent ranges i, the empirical dependency of failure intensity on the ambient temperature is obtained.

Table 4. Results of calculations of failure intensity in overhead MV power lines depending on ambient temperature

The analysis of the impact of ambient temperature on the failure intensity in overhead MV lines was conducted based on the data derived from 15 years of observation conducted within the premises of a large power distribution company in Poland. At the beginning of the observation a total of 1,050 km of overhead MV lines were used in the company. At the end of the observation the length amounted to 1,211 km.

The length of the lines in particular observation lines is presented in table 3. During the 15 years of observation a total of 1,950 failures in overhead MV lines occurred.

Table 4 presents the results of the conducted analysis of the dependency of failure intensity in overhead MV lines on ambient temperature.

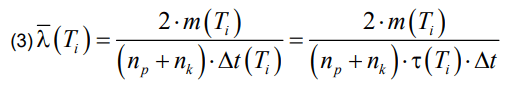

The failure intensity in overhead MV power lines depending on ambient temperature is presented in figure 3.

Determining the empirical waveform of function ¯λ(Ti) does not exhaust the problem of studying the dependency of failure intensity on ambient temperature. It is also important to determine the functional form of this dependency. The approximate function of the damage frequency presented in figure 3 is a fourth-degree multinomial expressed in the dependency (1), whereas k means the ambient temperature T. The approximate function factors of the line failure intensity in the ambient temperature function amount to: a = 21.29·10-6; b = -522.76·10-6; c = 18,110.54·10-6; d = 3,406.03·10-6; e = 8.8767. The correlation factor of the theoretical function with empirical data amounts to r = 0.91.

The hypothesis on the functional form was subjected to verification based on the character test and series test. As a result of using the character test, the following was obtained: l0 = min(l+ ,l– ) = min(15,12) = 12; l0 = 12 > 7 = la; lo ∊ Ra = (-∞,7). Therefore, at the weight level a = 0.05, there is no basis for rejecting the hypothesis on the functional form of distribution ¯λ = f(t). As result of using the series test, the following was obtained: n1 = l+ = 15; n2 = l– = 12; number of subsequent series k = 11. For the above values, the critical area covers the values k ≤ 9 and k ≥ 18. Therefore, at the weight level a = 0.05, there is no basis for rejecting the hypothesis on the functional form of distribution ¯λ = f(t).

Summary and final conclusions

The dependency of the failure intensity of power lines on the ambient temperature must be related to many factors. First of all, there is a considerable correlation between high temperatures and atmospheric discharges, and between low temperatures and icing and frosting on devices. These are factors that cause the vast majority of failures. Furthermore, high temperatures cause more difficult conditions of cooling the devices, which in the case of substantial loads leads to exceeding the acceptable temperatures. On the other hand, low temperatures lower the plasticity of most insulation and conductor materials. This causes that even small external forces can damage them. Lubricant materials used in movable connections also lose their properties. In connection with the reduction in the dimensions of elements constituting a movable connection (temperature expandability), this causes substantial resistance during movement and can lead to damage. A very dangerous phenomenon occurring at high temperatures, especially for porcelain elements (insulators, lightning rods), is their rapid cooling by rain after previous long-term heating. An analogous situation takes place for lightning rods operating at very low temperatures. In the case of arc ignition (e.g. due to a grid surge) during rapid cooling of the lighting rod’s insulator, it can be damaged due to substantial differences in the internal and external surface temperatures. Other phenomena that negatively affect the technical condition of devices and are related to extreme ambient temperatures are periodic temperature changes. In the hot summer period device elements become heated during the day. At night the temperatures are substantially lower, thus causing their cooling. Such periodic changes, with uneven temperature expandability of various materials, can lead to unsealing (e.g. transformer ladle) or loosening (e.g. connector contacts) of power device subassemblies. In the case of laminated insulation systems (e.g. cable heads, couplers, etc.) a possible damage mechanism at low temperatures is the destruction of insulation as a result of freezing of the moisture present in it. On the other hand, in periods of low temperatures the length of overhead line cables is reduced, thereby increasing their tension. Failures can occur in the case of any defects of the support structures or insulators. Low temperatures often cause problems with compressed air systems, especially with pressure valves that freeze up and are damaged if activated. An analogous situation takes place in the case of movable components of power devices. At low temperatures, they freeze to one another and become damaged at the attempt of mutual movement.

The impact of ambient temperature on the failure rate of power devices has been noticed for many years. However, no research aimed at determining this dependency in qualitative terms was conducted. The paper presents a method of designating the failure intensity of power structures in the ambient temperature function. The method was used to determine the dependency of failure intensity of overhead MV lines on the temperature at which they are used. The test results presented in the paper do not exhaust the impact of ambient conditions on the reliability of power structures. In further research, the author will attempt to develop multi-dimensional reliability models covering, aside from temperature, factors such as humidity, pressure, wind velocity, precipitation, atmospheric discharges, etc.

LITERATURA

[1] Bolzern P., Fronza G., Role of weather inputs in shortterm forecasting of electric load. International Journal of Electrical Power & Energy Systems, Volume 8, Issue 1, January 1986, Pages 42-46

[2] Chojnacki A. Ł., Analysis of the operating reliability of power distribution grids. Kielce University of Technology Publisher, Kielce, 2013

[3] Collective Work. Electrical Insulation Materials. Scientific and technical publishing house, Warszawa, 1965

[4] Collective Work. Electronics and telecommunication problems: Climate resilience and mechanical durability of electronic equipment. Wydawnictwo Komunikacji i Łączności, Warszawa 1968

[5] IEC 60068-2-1:2007 Environmental testing – Part 2-1: Tests – Test A: Cold.

[6] IEC 60068-2-14:2009 Environmental testing – Part 2-14: Tests – Test N: Change of temperature.

[7] IEC 60068-2-2:2007 Environmental testing – Part 2-2: Tests – Test B: Dry heat.

[8] IEC 60068-2-33:2002 Environmental testing – Part 2: Tests. Guidance on change of temperature tests.

[9] Johnson M., Gorospe G., Landry J., Schuster A., Review of mitigation technologies for terrestrial power grids against space weather effects. International Journal of Electrical Power & Energy Systems, Volume 82, November 2016, Pages 382-391

[10] Migdalski J. red., Reliability Engineering – Guide. ATR Bydgoszcz i Zetom Warszawa, 1992

[11] Migdalski J. red., Reliability guide. Mathematical basics. Wydawnictwo „WEMA”, Warszawa, 1982

[12] Military Standardization Handbook. Reliability Prediction of Electronic Equipment. MIL-HDBK 217B. U.S. Government Printing Office, Washington, 1974

[13] Narimani A., Nourbakhsh G., Ledwich G. F., Walker G. R., Optimum electricity purchase scheduling for aggregator storage in a reliability framework for rural distribution networks. International Journal of Electrical Power & Energy Systems, Volume 94, January 2018, Pages 363-373

[14] PN-N-50191:1993 Terminology of electrics – Reliability, quality of service.

[15] Rychtera M., Bartakova B., Tropic-proofing of electrical devices. Scientific and technical publishing house, Warszawa, 1966

[16] Sousa B. J. O., Humayun M., Pihkala A., Lehtonen M. I., Three-layer seasonal reliability analysis in meshed overhead and underground subtransmission networks in the presence of co-generation. International Journal of Electrical Power & Energy Systems, Volume 63, December 2014, Pages 555-564

[17] Sozański J., Reliability of electricity power supply. Scientific and technical publishing house, Warszawa, 1982

[18] Wróblewski Z., Multi-variant method of forecasting the durability of electro-magnetic AC contacts in current production. Wrocław University of Technology Publishing Houses, Wrocław, 1988

Autor: dr hab. inż. Andrzej Ł. Chojnacki, prof. PŚk, Politechnika Świętokrzyska w Kielcach, Katedra Energetyki, Energoelektroniki i Maszyn Elektrycznych, Aleja Tysiąclecia Państwa Polskiego 7, 25-314 Kielce, e-mail: a.chojnacki@tu.kielce.pl

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 98 NR 10/2022. doi:10.15199/48.2022.10.68