Published by Tejashree G. More, Pooja R. Asabe,Prof. Sandeep Chawda, (Department of Electrical Engineering, Bhivarabai Sawant Institude Of Technology and Research(w), Wagholi, Pune, India)

ABSTRACT In this paper the main power quality (PQ) problems are presented with there associated causes and consequences. The economic impact associated with PQ are characterized. Also this paper tries to give the solution for reducing the losses produced because of harmonics and increasing the quality of power at consumers’ side.

Keywords: Flywheel, Harmonics, Power Quality, Power Quality Cost, Supercapacitors.

I. INTRODUCTION

Nowadays, reliability and quality of electric power is one of the most discuss topics in power industry. There are numerous types of Quality issues and problems and each of them might have varying and diverse causes. The types of Power Quality problems that a customer may encounter classified depending on how the voltage waveform is being distorted. There are transients, short duration variations (sags, swells and interruption), long duration variations (sustained interruptions, under voltages, over voltages), voltage imbalance, waveform distortion (dc offset, harmonics, inter harmonics, notching, and noise), voltage fluctuations and power frequency variations. Among them, three Power Quality problems have been identified to be of major concern to the customers are voltage sags, harmonics and transients. This paper is focusing on these major issues.

II. POWER QUALITY

It is often useful to think of power quality as a compatibility problem is the equipment connected to the grid compatible with the events on the grid. Compatibility problems always have at least two solutions i.e., either clean up the power, or make the equipment tougher.

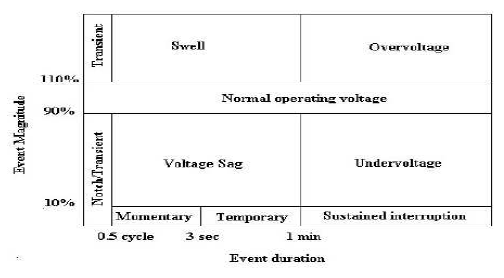

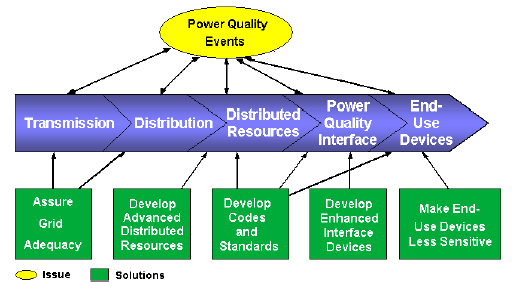

Both electric utilities and end users of electrical power are becoming increasingly concerned about the quality of electric power. Electrical PQ is the degree of any deviation from the nominal values of the voltage magnitude and frequency. PQ may also be defined as the degree to which both the utilization and delivery of electric power affects the performance of electrical equipment. From a customer perspective, a PQ problem is defined as any power problem manifested in voltage, current, or frequency deviations that result in power failure or misoperation of customer of equipment. Fig. 1 describe the demarcation of the various PQ issues defined by IEEE Std. 1159-1995.

III. NECESSITY OF POWER QUALITY AUDIT

a. Newer generation load equipment with microprocessor based controls and power electronic devices are more sensitive to power quality variations.

b. Any user has increase awareness of power quality issues. Such as interruptions, sags and switching transients.

c. Many things are now interconnected in a network. Failure of any component has more consequences.

d. Power quality problem can easily cause losses in the billions of dollars. So entire new industry has grown up to analyse and correct these problems.

e. The increase in emphases on overall power efficiency has resulted in continuous growth of application. Such as high efficiency adjustable speed motor drives capacitor use for power factor correction. These results in increase harmonic level which degrade the Power quality.

IV. POWER QUALITY ANALYSISINFORMATION AND STANDARDS

The quality of electricity has become a strategic issue for electricity companies, the operating, maintenance and management personnel of service sector and industrial sites, as well as for equipment manufacturers, for the following main reasons:

a. The economic necessity for businesses to increase their competitiveness

b. The wide spread use of equipment which is sensitive to voltage disturbance and/or generates disturbance itself

V. POWER QUALITY ISSUES

In an electrical power system, there are various kinds of PQ disturbances. They are classified into categories and their descriptions are important in order to classify measurement results and to describe electromagnetic phenomena, which can cause PQ problems. The categories can be classified below,

a. Short-duration voltage variations

b. Long-duration voltage variations

c. Transients

d. Voltage imbalance

e. Waveform distortion

f. Voltage fluctuation

g. Power frequency variations

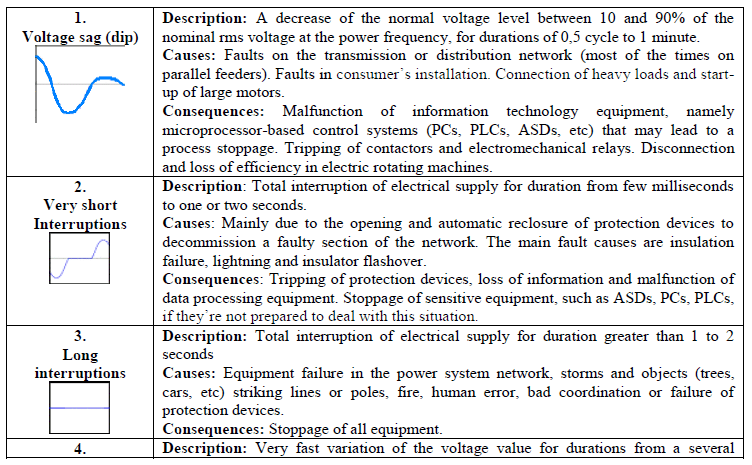

The most common types of PQ problems are presented in Table I.

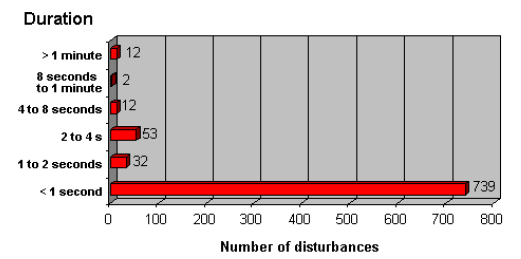

The most demanding processes in the modern digital economy need electrical energy with 99.9999999% availability (9-nines reliability) to function properly. Between 1992 and 1997, EPRI carried out a study in the US to characterize the average duration of disturbances. The result for a typical site, during the 6-year period is presented below.

Table I – Most common Power Quality problems [ 1], [2]

It is clear that not all these disturbances cause equipment malfunctioning, but many types of sensitive equipment may be affected. Another study of EPRI was undertaken, between 1993 and 1999, in order to characterize the PQ. This study concluded that 92% of disturbances in PQ were voltage sags with amplitude drops up to 50% and duration below 2 seconds.

5.2 COSTS OF POWER QUALITY PROBLEMS

The costs of PQ problems are highly dependant of several factors, mainly the business area of activity. Other factors, like the sensitivity of the equipment used in the facilities and market conditions, among other, also influence the costs of PQ problems.

A. Power Quality Costs Evaluation

The costs related to a PQ disturbance can be divided in:

1) Direct costs: The costs that can be directly attributable to the disturbance. These costs include the damage in the equipment, loss of production, loss of raw material, salary costs during non-productive period and restart costs. Sometimes, during the nonproductive period some savings are achieved, such as energy savings, which must be subtracted to the costs. Some disturbances do not imply production stoppage, but may have other costs associated, such as reduction of equipment efficiency and reduction of equipment lifetime.

2) Indirect cost: These costs are very hard to evaluate. Due to some disturbances and nonproductive periods, one company may not be able to accomplish the deadlines for some deliveries and loose future orders. Investments to prevent power quality problems may be considered an indirect cost.

3) Non-material inconvenience: Some inconveniences due to power disturbance cannot be expressed in money. The only way to account these inconveniences is to establish an amount of money that the consumer is willing to pay to avoid this inconvenience [2], [3].

B. Estimates on Power Quality Costs

Several studies have been made to evaluate the costs of PQ problems for consumers. The assessment of an accurate value is nearly impossible; so all these studies are based on estimates. Some of these studies are presented below

1) Business Week (1991): PQ costs were estimated on 26,000 million USD per year in the United States.

2) EPRI (1994): This study pointed 400,000 million USD per year for PQ costs in the United States.

3) US Department of Energy (1995): PQ costs were estimated on 150,000 million USD per year for United States.

) Fortune Magazine (1998): Stated that PQ costs were around 10,000 million USD per year in United States.

5) E Source (2001): A study comprising continuous process industries, financial services and food processing in the United States, estimated the average annual costs of PQ problems on 60,000 to 80,000 USD per installation.

6) PQ costs in EU (2001): Overall PQ costs in industry and commerce, in European Union, are estimated in 10,000 million EUR per year [6]. The estimates of the various studies differ a lot, but all point to a common factor: the PQ costs are enormous.

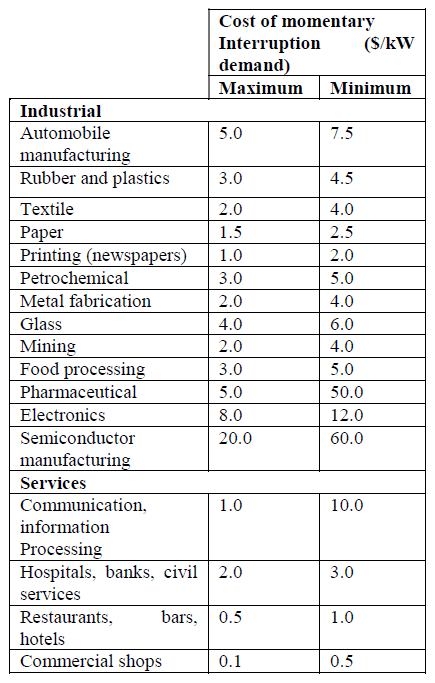

C. Costs of Momentary Interruptions

An interruption is the PQ problem with the most perceivable impact on facilities. Table II summarizes the typical costs of momentary interruptions (1 minute) for different types of consumers. The costs presented are without major investments in technologies to achieve ride-through capabilities to cope with the interruption.

Table II – Typical costs of momentary interruptions (1 minute, in $/kW demand, for different types of industrial and services facilities).

As it can be seen, the industrial sector is the most affected by interruptions, especially the continuous process industry. In the services sector, communication and information processing is the most affected business area.

The costs of interruptions are also function of its duration. Fig. 3 depicts the costs of interruptions against its duration.

5.3 SOLUTIONS OF POWER QUALITY PROBLEMS

The mitigation of PQ problems may take place at different levels: transmission, distribution and the end use equipment. As seen in Fig. 4, several measures can be taken at these levels.

5.3.1 GRID ADEQUECY

Many PQ problems have origin in the transmission or distribution grid. Thus, a proper transmission and distribution grid, with adequate planning and maintenance, is essential to minimize the occurrence of PQ problems.

5.3.2 DISTRIBUTED RESOURCES– ENERGY STORAGE SYSTEM

Interest in the use of distributed energy resources (DER) has increased substantially over the last few years because of their potential to provide increased reliability. These resources include distributed generation and energy storage systems.

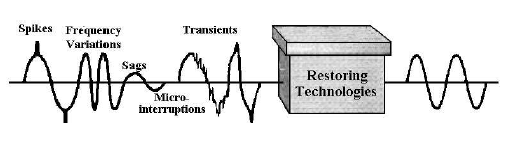

Energy storage systems, also known as restoring technologies, are used to provide the electric loads with ride-through capability in poor PQ environment.

Recent technological advances in power electronics and storage technologies are turning the restoring technologies one of the premium solutions to mitigate PQ problems.

The first energy storage technology used in the field of PQ, yet the most used today, is electrochemical battery. Although some new technologies still rule due to their low price and mature technology.

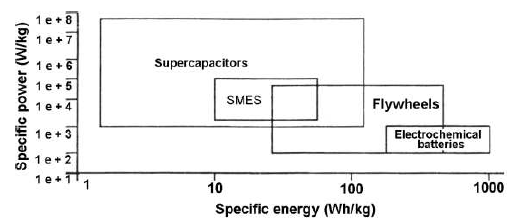

A. Flywheels

A flywheel is an electromechanical device use to store energy for short durations. During a power disturbance, the kinetic energy stored in the rotor is transformed to DC electric energy by the generator, and the energy is delivered at a constant frequency and voltage through an inverter and a control system. The flywheel provides power during a period between the loss of utility supplied power and either the return of utility power or the start of a back-up power system (i.e.,diesel generator). Flywheels typically provide 1-100 seconds of ride-through time, and back-up generators are able to get online within 5-20 seconds.

B. Supercapacitors

Supercapacitors (also known as ultracapacitors) are DC energy sources and must be interfaced to the electric grid with a static power conditioner, providing energy output at the grid frequency. A supercapacitor provides power during short duration interruptions or voltage sags.

C. SMES

A magnetic field is created by circulating a DC current in a closed coil of superconducting wire. The path of the coil circulating current can be opened with a solid-state switch, which is modulated on and off. Due to the high inductance of the coil, when the switch is off (open), the magnetic coil behaves as a current source and will force current into the power converter which will charge to some voltage level. Proper modulation of the solid-state switch can hold the voltage within the proper operating range of the inverter, which converts the DC voltage into AC power. SMES systems are large and generally used for short durations, such as utility switching events.

D. Comparison of Storage Systems

Fig. 7 shows a comparison of the different storage technology in terms of specific power and specific energy.

Fig. 7 shows the specific costs of energy storage devices.

The high speed flywheel is in about the same cost range as the SMES and supercapacitors and about 5 times more expensive than a low speed flywheel due to its more complicated design and limited power rating. But flywheel can be more cost effective than the battery.

5.3.3 DISTRIBUTED RESOURCES – DISTRIBUTED GENERATION

Distributed Generation (DG) units can be used to provide clean power to critical loads, isolating them from disturbances with origin in the grid. DG units can also be used as backup generators to assure energy supply to critical loads during sustained outages. Additionally DG units can be used for load management purposed to decrease the peak demand.

The most common solution is the combination of electrochemical batteries UPS and a diesel genset. At present, the integration of a flywheel and a diesel genset in a single unit is also becoming a popular solution, offered by many manufacturers.

5.3.4 ENHANCED INTERFACING DEVICES

Besides energy storage systems and DG, some other devices may be used to solve PQ problems. Using proper interface devices, one can isolate the loads from disturbances deriving from the grid.

A. Dynamic Voltage Restorer

A dynamic voltage restorer (DVR) acts like a voltage source connected in series with the load. The working principle of the most common DVRs is similar to Fig. 6. The output voltage of the DVR is kept approximately constant voltage at the load terminals by using a step-up transformer and/or stored energy to inject active and reactive power in the output supply trough a voltage converter.

B. Transient Voltage Surge suppressors (TVSS)

TVSS are used as interface between the power source and sensitive loads, so that the transient voltage is clamped by the TVSS before it reaches the load. TVSSs usually contain a component with a nonlinear resistance (a metal oxide varistor or a zener diode) that limits excessive line voltage and conduct any excess impulse energy to ground.

C. Constant Voltage Transformers (CVT)

CVT were one of the first PQ solutions used to mitigate the effects of voltage sags and transients. To maintain the voltage constant, they use two principles that are normally avoided: resonance and core saturation.

If not properly used, a CVT will originate more PQ problems than the ones mitigated. It can produce transients, harmonics (voltage wave clipped on the top and sides) and it is inefficient (about 80% at full load).

D. Noise Filters

Noise filters are used to avoid unwanted frequency, current or voltage signals (noise) from reaching sensitive equipment. This can be accomplished by using a combination of capacitors and inductances that creates a low impedance path to the fundamental frequency and high impedance to higher frequencies, that is, a low-pass filter. They should be used when noise with frequency in the kHz range is considerable.

E. Isolation Transformers

Isolation transformers are used to isolate sensitive loads from transients and noise deriving from the mains. In some cases isolation transformers keep harmonic currents generated by loads from getting upstream the transformer.

The particularity of isolation transformers is that any noise or transient that come from the source in transmitted through the capacitance between the primary and the shield and on to the ground and does not reach the load.

F. Static VAR Compensators

Static VAR compensators (SVR) use a combination of capacitors and reactors to regulate the voltage quickly. Solid-state switches control the insertion of the capacitors and reactors at the right magnitude to prevent the voltage from fluctuating. The main application of SVR is the voltage regulation in high voltage and the elimination of flicker caused by large loads.

G. Harmonic Filters

Harmonic filters are used to reduce undesirable harmonics. They can be divided in two groups: passive filters and active filters. Passive filters consist in a low impedance path to the frequencies of the harmonics to be attenuated using passive components. Several passive filters connected in parallel may be necessary to eliminate several harmonic components. If the system varies, passive filters may become ineffective and cause resonance.

Active filters analyse the current consumed by the load and create a current that cancel the harmonic current generated by the loads

5.3.5 DEVELOPE CODE AND STANDERDS

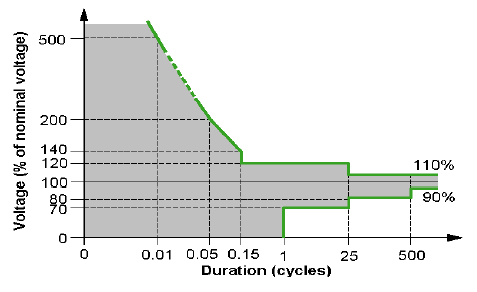

Some measures have been taken to regulate the minimum PQ level. One major step in this direction was taken with the CBEMA curve (Fig. 8), created by the Computer and Business Equipment Manufacturer’s Association. This standard specifies the minimum withstanding capability of computer equipment to voltage sags, micro-interruptions and overvoltages.

This curve, although substituted recently by ITIC (Information Technology Industry Council) curve (Fig. 9), is still a reference in the area of PQ. When the voltage is within the limits determined by the shaded zone, the equipment should function normally. When the voltage is comprised on the zone below the permitted zone, the equipments may malfunction or stop. When the voltage is comprised in the upper prohibited zone, besides equipment malfunction, damage on the equipment may occur.

Other standardization organizations (IEC, CENELEC, IEEE, etc) have developed a set of standards with the same purposes.

5.3.6 MAKE END USE DEVICES LESS SENSITIVE

Adding a capacitor with a larger capacity to power supplies, using cables with larger neutral conductors, derating transformers and adjusting undervoltage relays, are measures that could be taken by manufacturers to reduce the sensitivity of equipment to PQ problems.

VI. CONCLUSION

As conclusion, these Power Quality issues are unwanted phenomenon which are unavoidable but can be reduced using all techniques, but not limited to the techniques that have been discussed. There is no one mitigation technique that will suitable with every application, and whilst the power supply utilities strive to supply improved Power Quality. It means, Power Quality problem cannot be eliminated but we can reduce and try to avoid this problem form occur. The best way to avoid Power Quality problem is by ensuring that all equipment to be installed in the industrial plants are compatible with Power Quality in the power system. This can be achieved by procuring equipment with proper technical specifications that incorporate Power Quality performance of its operating electrical environment.

REFERENCES

[1] J. Delgado, “Gestão da Qualidade Total Aplicada ao Sector do Fornecimento da http://www.ijera.com 177 | P a g e Energia Eléctrica”, Thesis submitted to fulfilment of the requirements for the degree of PhD. in Electrotechnical Engineering, Coimbra, September 2002.

[2] M. Bollen, “Understanding Power Quality Problems– Voltage Sags and Interruptions”, IEEE Press Series on Power Engineering – John Wiley and Sons, Piscataway, USA (2000).

[3] M. McGranaghan, “Costs of Interruptions”, in proceedings of the Power Quality 2002 Conference, Rosemont, Illinois, pp 1-8, October 2002.

[4] D. Chapman, “Costs of Poor Power Quality”, Power Quality Application Guide – Copper Development Association, March 2001.

[5] EPRI, “Creating the Electricity Infrastructure for a Digital Society”, UIE-2000 Conference, Lisbon, 1-3, November 2000.

[6] H. Darrelmann, “Comparison of Alternative Short Time Storage Systems”, Piller, GmbH, Osterode, Germany.

[7] P. Ribeiro, B. Johnson, M. Crow, A. Arsoy, Y. Liu, “Energy Storage Systems for Advanced Power Applications”, Proceedings of the IEEE, vol 89, no. 12, December 2001.

Source & Publisher Item Identifier: Tejashree G. More et al. Int. Journal of Engineering Research and Applications http://www.ijera.com ISSN : 2248-9622, Vol. 4, Issue 4 ( Version 4), April 2014, pp.170-177.