Published by Jan ZAWILAK, Maciej GWOŹDZIEWICZ,

Department of Electrical Machines, Drives and Measurements, Wroclaw University of Science and Technology, Wroclaw, Poland

Abstract. This paper deals with issues relating to the start-up of AC motors with high load torque, presenting the results of measurements of current, voltage and power during the start-up of the following three types of motors: an asynchronous motor synchronized with a resistance starter, an asynchronous motor synchronizing with an eddy current starter, and a line start permanent magnet synchronous motor (LSPMSM). The measurement results, show that it is possible to use the direct start-up of a synchronous motor with permanent magnets and thereby eliminate external start-up systems.

Streszczenie. W pracy przedstawiono zagadnienia związane z rozruchem silników prądu przemiennego w układach o dużym momencie obciążenia. Pokazano wyniki pomiarów prądu, napięcia i mocy podczas rozruchu trzech typów silników: asynchronicznego synchronizowanego z rozrusznikiem rezystorowym, asynchronicznego synchronizowanego z rozrusznikiem elektromagnetycznym, synchronicznego wzbudzanego magnesami trwałymi. Na podstawie wyników pomiarów stwierdzono, że można zastosować bezpośredni rozruch silnika synchronicznego z magnesami trwałymi i wyeliminować zewnętrzne układy rozruchowe. Rozruch silników prądu przemiennego w układach o dużym momencie obciążenia

Keywords: electric machines, synchronous motors, permanent magnets, moment of inertia, start-up

Słowa kluczowe: maszyny elektryczne, silniki synchroniczne, magnesy stałe, moment bezwładności, rozruchy

Introduction

The copper ore extracted from mines has a copper content of approx. 0.96 – 2.5%. As a result of many complicated and energy-consuming technological processes (sifting, crushing, grinding, flotation, compaction and drying), a concentrate with a copper content of. about 25% is obtained. The concentrate is delivered to a smelter, where it is subjected to the processes of melting, converting and refining. The final products include, inter alia, electro refined cathodes with a 99.99% copper content. In addition, other metal elements (gold, silver, molybdenum) are recovered from ore deposits [2, 3, 5].

In the technological processes of copper ore enrichment, approximately 660 GWh of electricity is consumed annually, while the demand for this energy by electric drive systems amounts to about 95%. Electricity charges constitute approx. 30% of the value of production costs.

This is why it is important to look for innovative technical solutions which aim to save electricity. High-power, continuous-operation electric drive systems, in the case of which even a small increase in efficiency results in a large reduction in operating costs, are of particular importance. Ore grinding systems belong to such drives. They use more than half of the total electricity consumed by processing plants.

The drive systems of mills are characterized by very high inertia and difficult start-up (high resistive torque), especially when the mill is filled with muck. SAS type motors (Asynchronous Motor Synchronized, in Polish: Silnik Asynchroniczny Synchronizowany, with a rotor band winding and slip rings) to which a starting device (a three phase resistor or an electromagnetic device (the so-called eddy current starter)) is connected, are used in such drives. During start-up, the best features of the ring induction motor are exploited. In order to improve the operational parameters (mainly the power factor and efficiency), the rotor winding after start-up is supplied with constant current, and after synchronization the motor works as a synchronous motor [4, 6, 8].

The authors made an attempt to build a new AC motor which meets the demanding starting requirements and has a simplified start-up system – preferably a direct start-up using a direct connection to the power supply [1, 9, 10]. An SMH type synchronous motor excited by permanent magnets with a double squirrel cage rotor was proposed [7]. The motor is started by connecting the stator winding directly to the supply voltage. The two-pole winding generates sub-synchronous speed starting torque and the magnetic field of the permanent magnets synchronizes the motor.

The paper compares the start-ups of systems in which the mills are driven by the following 630 kW rated motors:

• an SAS type motor with a resistor starter,

• an SAS type motor with an electromagnetic (eddy current) starter,

• a synchronous motor excited with permanent SMH type magnets.

Start up of the SAS type Motor

The specifications of the SAS type motor are summarized in Table 1 and its view is presented in Figure 1.

Table 1. Specifications of the SAS 1832T type motor

A. Start-up of the SAS type motor with a resistor starter

Figures 2, 3 and 4 show, respectively, the stator starting current waveforms, the supply voltage (illustrating the voltage drop in the network) and the (active, reactive and apparent) power consumed by the SAS type motor with a four-stage resistor starter.

B. Start-up of the SAS type motor with an eddy current starter

Table 2 summarizes the basic specifications of the Wirleg-630 starter.

Table 2. Specifications of the eddy current starter

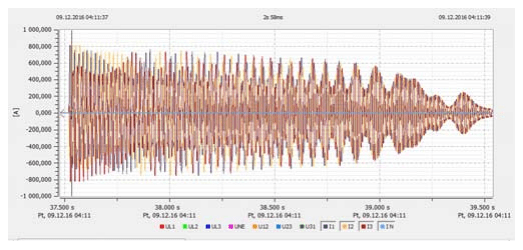

Figures 5, 6 and 7 show, respectively, the stator starting current waveforms, the supply voltage (illustrating the voltage drop in the network) and the (active, reactive and apparent) power consumed by the SAS type motor with the eddy current starter.

Start-up of the synchronous motor exited with permanent magnets

The basic specifications of the synchronous motor excited with permanent magnets are presented in Table 3 and its view is shown in Figure 8.

Table 3. Specifications of the synchronous motor with permanent magnets type SMH

This motor is designed for start-up through a direct connection to the network voltage.

Figures 8, 9, 9a, 10, 11 and 11a show, respectively, the stator starting current waveforms, the supply voltage (illustrating the voltage drop the network) and the (active, reactive and apparent) power consumed by the SMH type motor excited with permanent magnets.

Conclusions

Table 4 shows the most important electrical quantities for the three analysed start-ups for the highest stator current value.

On the basis of the measurements and the analysis of the results, carried out for the most important process of the operation of the motors which drive mills, it can be concluded that it is possible to use synchronous motors excited with permanent magnets instead of SAS motors. When synchronous motors with permanent magnets are used, the following effects are achieved:

• an increase in efficiency, which is constant for a large range of load changes,

• reactive energy compensation, and a constant maximum power factor,

• the elimination of the start-up system,

• the elimination of the excitation system,

•the use of the construction with the safety level of IP 54 reduces the failure rate of the motors, owing to the protection of the winding against flooding with process water,

• a reduction in the operating costs due to the elimination of the excitation system, the brushes, the slip rings and the drying of the windings,

• the minimization of motor maintenance operations,

• the simplicity of the drive power and control systems.

Table 4. The most important electrical quantities during the start-up of the analysed motors for the highest stator current value

REFERENCES

[1] Knypinski L., Jedryczka C., Demenko A., Influence of The Shape of Squirrel-Cage Bars on The Dimensions of Permanent Magnets in an Optimized Line-Start Permanent Magnet Synchronous Motor, XVII International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering (ISEF 2015), Valencia, Spain, 10-12 September 2015

[2] Pacholski E., Iskierski L., Analysis of the impact of the start-up method of propulsion motors on the parameters of the power network. Zeszyty Problemowe – Maszyny Elektryczne, No.2/2013

[3] Widak K., Analysis of the working synchronous motors that drive Mills, Diploma Project, 2017

[4] Ustun O.; Bayram Kara D., Evaluation of Spoke Type IPM Synchronous Motors for IE4 Efficiency Class, XIII International Conference on Electrical Machines (ICEM), 2018

[5] Zawilak J., Zawilak T., Energy-saving, high-power synchronous motors excited with permanent magnets, Przeglad Elektrotechniczny, R. 91, No 10, 2015

[6] Tian M., Wang X., Li G., Line-start permanent magnet synchronous motor starting capability improvement using polechanging method, IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), 2016

[7] Zawilak T., Zawilak J., Patent. Polska, nr 218489. “Rotor of a synchronous motor with permanent magnets “: H02K 1/27. Patent application. No. P 394666 dated 26/04/2011 / Wroclaw University of Science and Technology, 2011

[8] Zawilak T., Utilizing the deep bar effect in direct on line start of permanent magnet machines, Przegląd Elektrotechniczny, R. 89, No. 2b, pp. 177-179, 2013

[9] Dinh B. M., Tien H. M., Maximum efficiency design of line start permanent magnet synchronous motor, IEEE International Conference on Sustainable Energy Technologies (ICSET), 2016

[10] Knypinski L., Application of Bat Algorithm in the optimal design of line-start permanent magnet synchronous motor, 18th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering (ISEF) Book of Abstracts, 2017

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 95 NR 6/2019. doi:10.15199/48.2019.06.27