Published by Maytham S. AHMED1,2 Azah MOHAMED1 , Raad Z. HOMOD3 , and Hussain SHAREEF4,

Dept. of Electrical, Electronic & System Engineering, Faculty of Engineering & Built Environment, Universiti Kebangsaan Malaysia (1)

General Directorate of Electrical Energy Production- Basrah, Ministry of electricity, Iraq (2)

Dept. of Oil and Gas Engineering, Basrah University for Oil and Gas, 61004 Basrah, Iraq (3)

Dept. of Electrical Engineering, United Arab Emirates University, P.O. Box 155511 Al-Ain, UAE (4)

Abstract. In the last decades, home energy consumption has increased significantly due to increasing load demand in the residential sector. This paper presents a home energy management (HEM) algorithm to manage the home appliances in a house during a demand response (DR) event. The developed algorithm considers load appliances according to customer preference setting, priority of appliance, and comfortable lifestyle that can be changed at any given time and performs DR at appliance level. The load models are developed based on the operational and physical characteristics for the purpose of DR strategies. Appropriate residential load models are required to support the DR strategies and therefore air conditioner, water heater, electric vehicle and washing machine are chosen as the loads. The proposed HEM algorithm is shown to be effective in managing power consumption at appliances level and can maintain the total household power consumption below its demand limit (DL) without affecting the comfort level.

Streszczenie. W artykule predstawiono algorytm do zarządzania konsumpcja energii w gospodarstwach domowych. Algorytm zarządza enegią przy założonym poziomie dopuszczalnego limitu I bazuje na charakterystykach urządzeń podłączonych do sieci. Algorytm zarządzania konsumpcj a enegii w gospodarstwach domowych

Keywords: Home energy management, demand response, smart appliance, energy efficiency, peak load reduction.

Słowa kluczowe: konsumpcja energii, gospodarstwo domowe, algorytm HEM

Introduction

Electricity power consumption varies between seasons of the year, and days of the week, where the highest peak hour demands typically happens when the weather temperature is high. In several situations, especially in the summer season, end user has to pay more than the normal electricity price because of increased energy consumption for cooling purposes [1]. Residential load represents the largest energy consumption and to reduce the electricity generation cost, DR is practiced by utility by decreasing the peak demand and shifting the home appliances from peak hour demand to off-peak hours [2]. Thus, shifting and scheduling electricity usage to off peak hours is essential to both end users and utility companies for reducing cost of electricity [3].

DR refers to a program which offers incentives to homeowners who curtail their energy use during times of peak demand. DR applications are designed to reduce peak demand and encourage end-users to reduce energy consumption.

In recent years, residential HEM with DR has become an active topic for many research studies [4]. Previous research highlighted that the use of DR is essential to improve HEM system in the domestic sector [5]. For efficient HEM system with DR, a variety of consumer electronic devices must be controlled using the internet and the home network for remote management so as to reduce peak demand that may lead to reduce risk of outages at distribution and transmission networks [6]. Load models need to be developed to evaluate DR at the distribution circuit level so as to study customer behaviours. Recently, various optimization techniques have been used to assist homeowners to create optimal appliance scheduling and shifting of energy usage based on variety pricing scheme programs, feed-in tariffs, and comfort settings [7]. In [8], the immune clonal selection algorithm has been developed for HEM to reduce the power consumption of air conditioner and water heater. A framework of HEM system using artificial bee colony optimization algorithm has been developed to improve the system by scheduling the home appliances [9]. An optimal HEM approach based on the game theory is used to reduce the peak-average electricity consumption rate [10]. The rule based technique has been applied to reduce electricity bill considering residential DR application [11]. In [12], the operation of the home appliances schedule is according to the ever-changing real time prices and the tariff rate based DR program. A smart plug with a wireless Zigbee sensor developed for measuring power consumption of electrical appliances in the HEMS [13].

One of the major challenges in scheduling household appliances is to minimize the energy consumption without affecting the customer’s comfort. However, most of previous research works have focused on saving energy to reduce electricity bill without considering residential comfortable lifestyle.

In this paper, a HEM algorithm has been developed by considering customer’s comfort for household peak load reduction to reflect any desired DR event. The DR enabled load model at the appliance level is used to achieve energy savings and reduce electricity bill based on shifting the operation of several appliances to specific off peak time. In this study, four home appliance models have been considered according to the customer preferences and priority of appliances that include air conditioner (AC), water heater (WH), electric vehicle (EV), and washing machine (WM). Hence, the proposed HEM algorithm is developed to reduce power consumption at peak time and shifting the appliances to off peak time without affecting the customer’s comfort.

Demand response enabled home load appliances

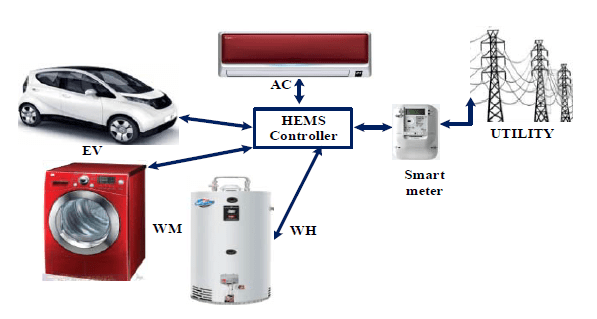

To develop a HEM algorithm for residential customers with DR applications, there is need to know the characteristics of home appliances and preferences of the loads. In this research, only controllable loads such as AC, WH, EV, and WM are deemed to be controlled according to priority of appliances, comfort level and customer preferences, so as to participate in the HEM system. The physical model of the loads is used as an appliance that is considered in the developed HEM algorithm. Figure 1 shows the HEM architecture with AC, WH, EV, and WM as appliances connected to the controller.

In Figure 1, the DR signal with information on the duration, situation and amount of load to be shed is received directly from a smart meter in the HEM system [14]. Thereafter, the HEM algorithm controls the off/on states of the appliances according to the demand limit, appliance priority, DR request and comfort level set by the consumer. The characteristics and preferences of the loads are shown in Table 1.

Table 1. Load priority and characteristics

Table 1 show that the first priority is AC and that the room temperature should be maintained in the range of 23.33–25.56°C. The second priority is WH with the hot water temperature maintained within the acceptable range of 43.33–48.8°C. EV is the third priority in which EV is assumed to have a fully battery charged by 8:00 morning at the next day. For WM, a consumer can identify its completion time and maximum on time of heating coils as 90 minutes. Other non-controllable loads are assumed to exist but are not considered in the system. The following subsection describes the load characteristics of AC, WH, EV and WM.

Air conditioner

An AC extracts unwanted heat from an area. When a demand limit is enforced and the AC is turned on, while the room temperature maintains within a comfortable range, the controller will impose the AC to turn off. If the temperature of room reaches its maximum allowable temperature, the AC unit will turn on, and the room temperature will be regularly reduced. At the time the room temperature decreases to its allowable set point temperature of, the main switch will turn off the AC and the temperature of room will maintain within the comfort level. In the case when the room temperature is between 23.33 and 25.56°C, the controller will keep the AC at the status of devices as shown in Eq. (1)

where mhvac is the status of device, mhvac,=1 device is switched on, and if mhvac,,= 0 device is switched off, Thvac,t is the temperature of room in °C at time interval t. The AC power consumption (Phvac,t) can be calculated by using:

Electric water heater

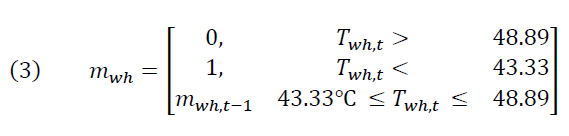

A domestic WH consists of a thermostat to sense temperature and switch ON / OFF to heat the water [15]. When the water temperature reaches its minimum allowable temperature of set point, 43.33°C, the WH will switch on to maintain the temperature of water at its comfortable range. If the temperature reaches its maximum allowable temperature of set point,48.89 °C, then the WH will switch off the heater. When the water temperature is within 43.33– 48.89 °C, the heater switch status will keep the previous device state. In the simulation, the second highest priority is WH and it is the second to the last device to be switched off.

The status device of water heater (mwh) at a given interval time is given as follows

Where mwh is the status of device, mwh=0 means the device is switched off, mwh=1 indicates that the device is switched on and Twh,t is the temperature of hot water in °C at interval time t.

The WH power consumption in kW (Pwht) at a given time interval can be determined using,

where Pwh is the amount of WH power rated in kW.

Electric vehicle

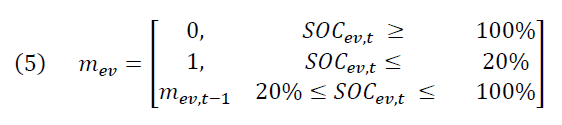

Battery is used to power up the motor of EVs. To model an EV, there are three parameters that should be taken into account; the rated charging power, plug-in time and state of charge (SOC) battery. The SOC of an EV battery is assumed to vary between 20% and 100% [16]. The time it takes to fully charge an EV depends on rated charging power, plug-in time and the battery SOC. In this research, EV is assumed to be plugged in when its battery SOC reaches 20% and the EV will not be used until the battery is fully charged. The switch status of EV (mev) at time intervals can be calculated using,

where mev is the device status, mev= 0 means that the appliance is switched off, mev=1 means the appliance is switched on, and SOCev,t is the battery SOC in the time interval.

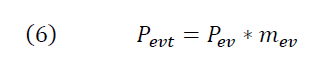

The EV power consumption in kW, Pevt at a given time interval can be determined by

where Pev is the amount of rated EV power in kW.

Washing machine

The electrical power consumption of a WM are rotating tumbler motor and heating coils. The load model of a WM and rated power for each time interval is adopted from [18]. A WH will switch on and need at least a 90-minute interval time so as to complete its job. The WH will switch off the motor, when the total on time arrived to the wanted time. The switching status of WM (mwm) can be determined as follows:

where mwm is the device status, mwm=0 means the appliance is switched off, mwm=1 means the appliance is switched on, and twm,t is the time interval for WM in minutes.

The WM power consumption in kW, Pwmt at a given interval time can be determined by

where Pwm is the amount of WM power rated in kW

Proposed HEM algorithm

The proposed algorithm is developed such that it can control AC, WH, EV, and WM and switch customer load so as to decrease the cost of electrical power consumption. The HEM algorithm starts by reading the data and information of all the above mentioned appliances. Each appliance is compared with several set points including load priority, power consumption and customer preference settings on the temperature of AC and WH. If the total electrical power consumption (PT) is greater than the demand limit (DL), the algorithm will turn OFF the lower appliance priority starting with WM, and force the loads to shift their operating time after ending the period of DR event in order to keep the total power consumption below its DL. In addition, the HEM algorithm issues a control signal to turn ON the appliance when the total household load is below its DL level. In this way, the HEM will optimize the scheduling of the appliances while maintaining the PT below its DL. The HEM algorithm is illustrated in terms of a flowchart as shown in Figure 2.

The proposed HEM algorithm implementation steps are described as follows:

i. From Table 1, read the characteristic of all appliances such as its rated power.

ii. Specify the user input data such as load priority, hot water temperature, room temperature, comfort level, real time pricing (RTP), and user demand limit (UDL).

iii. Read utility data signal of DR, demand limit in kW and the value of load shed (LS).

iv. The new demand limit (NDL) is determined by using equationNDL = UDL – LS.

v. Specify the device status for all appliances by using equations (6), (7), (9) and (11) and using the household electrical energy consumption equations (4), (8), (10) and (12) to determine the current demand (D).

vi. Update the appliances status such as the priority number of devices in service.

vii. Apply the condition in which if NDL is greater than D, then go to step ii.

viii. If the NDL is lower than D, then the appliance will switch OFF according to the level of comfort and priority of appliance and go to step v.

Simulation results

The simulation results and the performance of the proposed HEM algorithm in managing the consumption of electrical appliances as described accordingly. Two case studies were considered to describe the implementation of the algorithm. The first case is without applying DL so as to clarify the performances of AC, WH, EV, and WM as shown in Figure 3. The parameters and model specifications, such as the dimensions of WM and car characteristics, are taken from [17, 18].

The AC unit maintains the temperature of room at a comfortable range by turning OFF/ON as shown in Figure 3(a). More time is needed to cool a room at noon and hence, more power is consumed. The variation of WH temperatures with ON/OFF characteristics is shown in Figure 3(b). The WH operates to bring the temperature of water to the range of comfort level set at 43.33– 48.89°C. Similarly, at midnight the EV starts charging with 20% state of charge, as depicted in Figure 3(c). The EV is fully charged in five hours and forty-eight minutes. In Figure 3(d), the WM operates twice at 12:00 p.m and 6:00 p.m consuming 4 kW. Each time, the WM needs at least one and a half hours to complete its job. Finally, the total the household power consumption, PT is shown in Figure 3(e). The figure indicates that the maximum demand cannot be controlled and it depends on the device usage time.

In the second case, assumed the DR event is imposed by the power utility with 2 kW DL between 17 to 22 hours, as shown in Figure 4.

With DL, the WM, WH and EV have to be switched OFF and only one appliance which is the AC can be operated and draws 1.25 kW. The WM and WH require their schedules to be shifted after the period of DL. The results explain the ability of the proposed HEM algorithm in preserving total electrical energy consumption below the DL value. The algorithm prevents exceeding the total power consumption of the selected DL value.

Conclusion

A HEM algorithm with DR has been developed to schedule the operation of home appliances to save energy costs by considering customer convenience as well as characteristics of electric appliances. Accurate load models considering AC, WH, EV and WM have also been developed according to its operational and physical characteristics. The HEM algorithm has been implemented by considering the operation of loads such as AC, WH, EV and WM with DR signal to alleviate high energy consumption in the home. The results of the HEM algorithm showed that it is capable of preserving the total electrical energy consumption below the selected DL value and managing household loads taking into consideration customer’s preference settings and load priority. The algorithm can easily be implemented in homes because of its flexibility in controlling different types of home appliances.

Acknowledgment: The authors gratefully acknowledge University Kebangsaan Malaysia for the financial support on the project under the research grant DIP-2014-028

REFERENCES

[1] Zhang X., Shahidehpour M., Alabdulwahab A., Abusorrah A., Hourly Electricity Demand Response in the Stochastic Day-Ahead Scheduling of Coordinated Electricity and Natural Gas Networks, IEEE Trans on Power Syst. 31 (2016) 592-601.

[2] Maharjan S., Zhu Q., Zhang Y., Gjessing S., Basar T., Demand Response Management in the Smart Grid in a Large Population Regime, IEEE Trans on SG. 7 (2016) 189-199.

[3] Moreno-Munoz A., Bellido-Outeirino F.J., Siano P., Gomez-Nieto M.A., Mobile social media for smart grids customer engagement: Emerging trends and challenges, Renewable and Sustainable Energy Reviews. 53 ( 2016)1611-1616.

[4] Ahmed M.S., Mohamed A., Homod R. Z., Shareef H., Real time optimal schedule controller for home energy management system using new binary backtracking search algorithm, Energy and Buildings. 138 (2017) 215-227.

[5] Kushiro N., A Basic Study for Realizing Life Event Sensor for Home Energy Management System, Knowledge-Based information systems in Practice. Springer International Publishing, (2015) 21-38.

[6] Patel K., Khosla A., Home energy management systems in future Smart Grid networks: A systematic review, IEEE NGCT. (2015) 479-483.

[7] Gudi N., Wang L., Devabhaktuni V., A demand side management based simulation platform incorporating heuristic optimization for management of household appliances, Int. J. Electr. Power Energy Syst. 43 (2012) 185–193.

[8] Hong Y. Y., Chen C. R., Yang H W., Implementation of demand response in home energy management system using immune clonal selection algorithm, IEEE CEC conf. (2015) 3377-3382.

[9] Zhang Y., Zeng P., Zang C., Optimization algorithm for home energy management system based on artificial bee colony in smart grid, IEEE CYBER conf. (2015) 734-740.

[10] Mohsenian-Rad A H., Leon-Garcia A., Optimal residential load control with price prediction in real-time electricity pricing environments, IEEE Trans on SG. 2 (2010)120-133.

[11] Ahmed M. S., Shareef H., Mohamed A., Ali J. A., Mutlag AH. Rule Base Home Energy Management System Considering Residential Demand Response Application, Appl Mechanics & Materials. 785 (2015) 526-531.

[12] Li X. H., Hong S. H., User-expected price-based demand response algorithm for a home-to-grid system, Energy. 64(2014) 437-49.

[13] Ahmed M.S., Mohamed A., Homod R. Z., Shareef H., Sabry A. H., Khalid K.B., Smart plug prototype for monitoring electrical appliances in Home Energy Management System, IEEE SCOReD conf. (2015) 32-36.

[14] Wehierek P., Konarski M., Electricity measurement accuracy in the smart metering system, Electrical review, R. 91 NR 3 / 2015.

[15] Ahmed M.S., Mohamed A., Homod R. Z., Shareef H., Khalid K., Modeling of Electric Water Heater and Air Conditioner for Residential Demand Response Strategy. International Journal of Applied Engineering Research. 11 (2016) 9037-9046.

[16] Fiori C., Ahn K., Rakha H. A., Power-based electric vehicle energy consumption model: Model development and validation, Applied Energy. 168 (2016) 257-268.

[17] Chi S., Zhang Z., Xu L., Sliding-mode sensorless control of direct-drive PM synchronous motors for washing machine applications, IEEE Trans on IA. 45 (2009) 582-90.

[18] Ahmed M.S., Mohamed A., Homod R. Z., Shareef H., Hybrid LSA-ANN Based Home Energy Management Scheduling Controller for Residential Demand Response Strategy, energies. 9 (2016) 716.

Authors: Maytham S. Ahmed is a PhD student in the Department of Electrical, Electronic and Systems Engineering, Universiti Kebangsaan Malaysia (UKM), E-mail: eng_maitham@yahoo.com. Azah Mohamed is a professor in the Department of Electrical, Electronic and Systems Engineering, Universiti Kebangsaan Malaysia (UKM), E-mail: azah@eng.ukm.my. Raad Z. Homod is a professor in the Dept. of Petroleum and Gas Engineering, Basrah University, Iraq, E-mail: raadahmood@yahoo.com. Hussain Shreef is a professor in the Department of Electrical Engineering, United Arab Emirates University E-mail: hussain_ln@yahoo.com.

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 93 NR 3/2017, doi:10.15199/48.2017.03.46.