Published by Jacek CHĘCIŃSKI, Zdzisław FILUS, Silesian University of Technology, Department of Electronics, Electrical Engineering and Microelectronics

Abstract. Modern replacements for 230V AC lamps with the bases E14 and E27 are mainly based on LEDs. Today the efforts of their designers are concentrated, in particular, on elimination of detrimental effects associated with the flicker characteristic of the LED lamps supplied from the 230 VAC grid. This paper presents a simple supply circuit of a converter-less LED lamp supplied from the 230 VAC grid which features a stable luminous flux and no inrush current at turn-on. The design criteria are based on ensuring the conformance to the legally binding EMC regulations.

Streszczenie. Współczesne zamienniki żarówek z trzonkami E14 i E27 oparte są głównie na diodach LED. Obecnie wysiłki projektantów tych lamp ukierunkowane są, w szczególności, na eliminację negatywnych zjawisk związanych z migotaniem lamp LED zasilanych z sieci 230 VAC. W pracy opisano prosty układ bezprzetwornicowej lampy LED ze stabilnym strumieniem światła zasilanej z sieci 230 VAC bez udaru prądu podczas załączania. Kryteria projektowe zostały oparte na zapewnieniu zgodności z uregulowaniami dotyczącymi kompatybilności elektromagnetycznej. (Prosta lampa LED ze stabilnym strumieniem świetlnym zasilana z sieci 230 VAC bez udaru prądu podczas załączania).

Keywords: SSL, LED lamp, inrush current, stability of the luminous flux

Słowa kluczowe: SSL, lampa LED, udar prądu, stabilność strumienia świetlnego

Introduction

In order to use LED lamps as replacements for ordinary bulbs with the bases E14 and E27 their designers must solve a number of problems. The most important of them concern the capability of fitting the electronic circuit into a relatively small space inside the lamp and ensuring its proper operation at an elevated temperature. Modern LEDs are characterized by a very high luminous efficacy (over 160 lm/W) and a high energetic efficiency (reaching 40%), which is understood as a ratio of the power of the emitted electromagnetic wave (in the visible light range) to the supplied electric power. To ensure the equivalent luminous flux of LED lamps which are considered as replacements for ordinary bulbs whose rated power was usually within the range 10–150 W, it should be expected that the required power of LED lamps will be included, roughly, between 2 W and 20 W. If we consider the efficiency of LEDs solely, we must assume that at least 60% of the electric power drawn by the lamp from the grid will be converted to heat. In addition, the efficiency of the supply system and aging of LEDs will also contribute to the temperature rise in the lamp, so while designing a heat sink for an LED lamp it is reasonable to assume that the whole electric power drawn by the lamp may be converted to heat. In practice, the internal temperature of 10–15 W LED lamps, whose shape is expected to imitate the old incandescent lamps, may often exceed 100°C. Due to that some problems may arise concerning the use of electronic components. Although individual electronic components and modern LEDs may operate above 100°C (with decreased durability, remaining, however, at an acceptable level), such excessive temperatures may make impossible proper operation of advanced integrated circuits (e.g. drivers for switching converters), electrolytic capacitors and cored inductive components.

Each electronic product that is to be offered on the consumer market of the European Union must conform to the respective legally binding regulations. In the case of LED replacements for tungsten lamps the most difficult task of their designers is to comply with the Electromagnetic Compatibility (EMC) Directive. In the standard harmonized with this directive [1] the allowed levels of radioelectric disturbance emissions are specified together with the acceptable limits for harmonic components present in the supply current drawn from the 230 VAC grid. To meet the requirements stated in the standard, less or more complicated EMI (Electro-Magnetic Interference) filters have to be usually used together with the chokes correcting the waveform of the supply current. It should be noticed that the requirements of the standard differ depending on the type of equipment (e.g. lighting equipment) and the active power drawn by the equipment from the 230 VAC grid.

The supply circuits used in LED lamps (replacements for conventional 230 VAC bulbs) can be basically divided into three categories. In the first category the 230 VAC line voltage is rectified and after smoothening the ripple with a capacitor it feeds a DC/DC converter operated at a high frequency [2]. Due to the principle of operation, based on commutation of voltage and current, they must include RFI (Radio Frequency Interference) filters. The second group includes designs without any switching converters in which a few tens of series connected LEDs or the so called COB (Chip On Board) modules are used, whose total operating voltage is usually within a range 150–250 VDC [2]. Such lamps also include electrolytic capacitors to reduce the ripple of the rectified 230 VAC voltage and simple current regulators to stabilize the current flowing through the LEDs. LED lamps from the third group do not include any electrolytic capacitors. They are sometimes referred to as lamps with sequential supply. The idea of their operation is based on using a few strings of LEDs which become gradually connected in series to the previously conducting ones as the rectified line voltage increases and then, as the supply voltage decreases, they are turned off in reverse order [3, 4]. The current supplying the LED strings being connected in sequence is usually shaped as a staircase waveform in order to resemble a sine wave. The most important advantages of this solution are: a close to 1 value of the Power Factor (PF), high luminous efficacy of the lamp, fairly simple design and high durability (the lamp does not include electrolytic capacitors whose lifetime at high temperatures is a few times shorter than the lifetime of LEDs). On the other hand, the essential disadvantage of such lamps, resulting directly from their principle of operation, is high variability of the generated luminous flux, known as flicker. Due to that these lamps are not recommended for general lighting applications but many efforts are made to reduce this flicker [5,6].

Today, the lamps which are the most widely available on the market as replacements for conventional bulbs are the LED lamps from the second group discussed above. Stability of the luminous flux produced by these lamps is dependent on the capacitance of the electrolytic capacitor at the output of the 230 VAC rectifier. To minimize flicker and stroboscopic effects, this capacitance should be possibly large and chosen with a decent surplus in order to counteract its reduction resulting from operation at a high temperature. However, by increasing this capacitance it may become more difficult to satisfy the restrictive requirements of the standards harmonized with the EMC Directive which describe the acceptable waveform of the supply current or the allowed limits for harmonic components. A large value of this capacitance contributes also to excessive current surges at start-up of the lighting installation. This is especially a serious problem when many lamps are being turned on at the same time. Figure 1 shows the waveform of the supply current drawn by a 13 W LED lamp (equivalent to a 100 W incandescent bulb) from the moment of its turn-on.

The initial peak value of the current, which is a few dozen times greater than in steady-state operation, causes problems difficult to solve by designers of lighting installations. The amplitude of the inrush current can greatly change depending on the current value of the line voltage at the very moment of turning the lamp on. Because of that current surge the contacts of switches and contactors become burnt much faster. Therefore, it is necessary to use slow circuit breakers for overcurrent protection of lighting installations or to choose their current rating greater than resulting from the power balance. Another problem appears when LED lamps are used for emergency lighting to illuminate escape routes, where the voltage 230 VAC is obtained from DC/AC converters supplied from batteries. A rectifier with a large filtering electrolytic capacitor is the worst type of load for DC/AC converters. Large amplitudes of the inrush current disturb the start-up of the converter and due to a greatly non-linear load distortions of the sinusoidal voltage appear which are difficult to eliminate [7].

Requirements concerning the waveform of the supply current for devices connected to the 230 VAC grid

The acceptable distortions (allowed limits for harmonic components) of the supply current drawn by a load connected to a single-phase power grid have been specified in regulations concerning electromagnetic compatibility. According to the standard PN-EN IEC 61000- 3-2 [1] LED lamps are classified as loads belonging to the very restrictive Class C. However, in Section 7.4.3 of the standard less restrictive requirements are specified for lighting equipment with the power rating not exceeding 25 W. Lamps with the power between 5 and 25 W must conform to at least one of the three specified sets of requirements. The easiest to comply with and the most often chosen by designers is the second set [1], according to which the third harmonic of the supply current must no exceed 86% of the fundamental current and the fifth is limited to 61%. In addition, the waveform of the input current must reach 5% of its peak value before or at 60° (t ≈ 3.33 ms for a 50 Hz line voltage), reach the peak value before or at 65° (t ≈ 3.61 ms) and not fall below 5% of the peak value before 90° (t = 5 ms). The angle values are referenced to any zero crossing of the fundamental supply voltage. The 5% current threshold is referenced to the highest absolute peak value which appears in the measurement window and phase measurements are made in the cycle which includes this absolute peak value. It should be noted that the criteria described above were specified a few dozen years ago and initially they referred to discharge lighting equipment only (mainly compact fluorescent lamps – CFL).

In turn, the third set of requirements was introduced fairly recently, so it is very likely that the lamps complying with these requirements will be allowed to be commercially offered for the longest time. In this group of requirements the total harmonic distortion THD of the supply current must not exceed 70%, and the allowed limits for the harmonics, expressed as a percentage of the fundamental current, are: the second – 5%, the third – 35%, the fifth – 25%, the seventh – 30%, the ninth and eleventh – 20% [1]. As for today, the standard PN-EN IEC 61000-3-2 does not specify any limits on distortion of the supply current for lamps with a rated power less than 5 W.

A modified method of supplying LED lamps

Figure 2a shows the circuit diagram of the proposed modification of the supply circuit for LED modules.

Instead of a choke shaping the waveform of the supply current (according to the second set of requirements specified in Section 7.4.3 of the standard [1]) an IC current regulator is used. In this case the waveform of the supply current becomes rectangular (Fig. 2b) and its amplitude is independent of both the capacitance and the amount of charge in the electrolytic capacitor, which filters the voltage waveform across a string of LEDs connected in series. The proposed solution completely eliminates harmful current surges when the lamp is being turned on. What is more, as it is possible to use electrolytic capacitors with much higher capacitance, the luminous flux generated by the lamp can be much better stabilized.

Although the presented circuit seems to be a very simple and obvious solution, it is not used by manufacturers or, at least, the authors of this paper have not been able to find a similar solution on the consumer market. Manufacturers often refrain from modifying their established products in order not to bear the costs of tests and acquiring the necessary certificates for a new product. In most cases, the input circuits of LED lamps offered on the market have been based on solutions transferred from CFLs. The compliance of these solutions with the standard PN-EN IEC 61000-3-2 has been declared on the basis of satisfying by them the second set of requirements presented in Section 7.4.3. For the proposed circuit it would be more appropriate to consider the conformance with the third set of requirements rather than the second one. The rectangular waveform of the supply current can be very easily decomposed into harmonic components and, then, refer their amplitudes to the maximum levels indicated in the standard. Apart from that, the third set of requirements has been introduced to the standard most recently, so it is justified to expect that it will remain in force with no modifications for the longest time.

The waveform i(t) of the supply current drawn by an LED lamp from the 230 VAC grid can be represented by the Fourier series with A0 = 0:

The Fourier coefficients are dependent on the moments tON and tOFF at which the current i(t) reaches its amplitude (±IA) and drops to zero, respectively, in each half-period of the sinusoidal supply voltage 230 VAC. If the capacitance C of the filtering capacitor is sufficiently large to ensure that the peak-to-peak ripple will be much smaller than the average voltage across the capacitor, we may assume that the waveform i(t) is close to symmetry and tOFF ≈ T/2 – tON (where T = 20 ms). The value of tON is dependent on the currents IA and IB adjusted in both regulators and can be found from the charge balance for the capacitor:

The coefficients Ak and Bk result from the equations:

The coefficients Bk obtained from (5) are zero for even harmonics (k = 2N, where N is a natural number), whereas odd harmonics (k = 2N – 1) are given by the following:

for k = 1, 3, 5, 7, 9, 11 …

The coefficient THD can be found from (7):

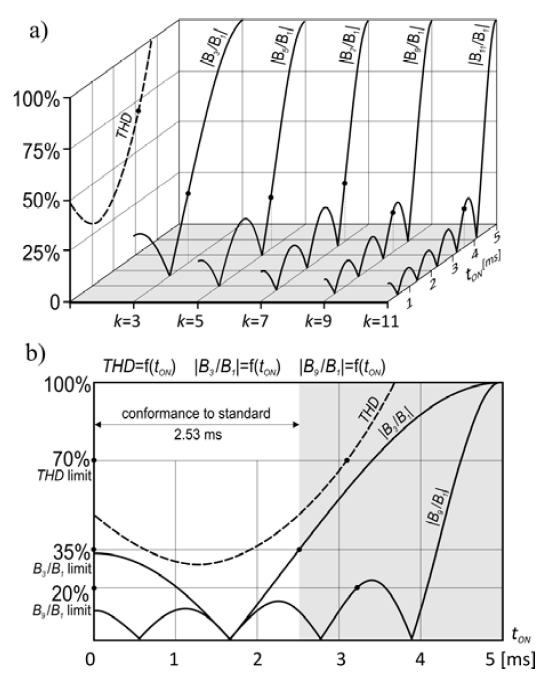

where IRMS is the RMS value of the supply current and I1 is the RMS value of its first harmonic. Figure 3 shows the percentage THD and normalized amplitudes of harmonics |Bk/B1| as functions of tON.

Analyzing the above plots we can notice that the third set of requirements from Section 7.4.3 of the standard [1] will be satisfied by the circuit from Fig. 2a, if the moment tON is smaller than 2.53 ms. In [8] it has been shown that in order to obtain high efficiency of an LED lamp with a single string of diodes, which is fed with a rectangular current waveform from Fig. 2b, the value of tON should be possibly high. In the case that we consider here it should be close to 2.53 ms with some margin necessary to allow for the spread of parameters of the used components, the temperature effects and the allowed variation of the grid voltage 230 VAC.

If we assume that the regulators IA and IB operate properly with a negligible voltage drop across them and the RMS value of the line voltage is 230 V, the total power drawn by the lamp and the power transferred to the LEDs with the series current regulator IB are given by (8) and (9):

The determination of the optimum length of the LED string is more critical here than for lamps without the filtering capacitor [8]. This length (number of diodes) should be smaller than the exact value resulting from the conduction voltage of a string for a given value of tON:

First of all, we should prevent the situation where the decrease in the voltage across C will cause a change in the current IB (the capacitance should be preferably large). Such a situation will not cause any significant change in the waveform of the supply current and the requirements specified in Section 7.4.3 of the standard [1] may remain satisfied. However, in the previously stable luminous flux a variable component will appear, increasing considerably an important parameter known as Percent Flicker [5, 6]. To prevent that, the number of LEDs initially calculated as a maximum number from (10) should be decreased by taking into account voltage drops across the current regulators IA and IB (the minimum values necessary for correct operation), the permissible reduction of the 230 VAC grid voltage (-10% according to the binding standard [9]), the effect of temperature on the forward voltage drop for the LEDs used in the lamp (ΔUF/ΔT) and the ripple voltage across the capacitor.

Summary

The main objective of this paper has been to prove that a simple solution of the supply circuit of LED lamps used as replacements for conventional 230 VAC bulbs (Fig. 2a), which is different from the commonly used ones, has a number of advantages. First of all, the conformance to the binding EMC standard [1], according to Section 7.4.3, has been based on the third set of requirements rather than on the less rigorous second one. The most important advantage is the possibility of using a large filtering capacitor thanks to which a stable luminous flux is guaranteed in a simple way. What is more, the inrush current is eliminated when the lamp is being turned on (Fig. 4).

The calculations and plots of harmonics contents have been verified by measurements. It should be noted that the calculations were carried out for an ideal rectangular waveform of the supply current (Fig. 2b), which is a worse case than the real one. In a real circuit it is easier to satisfy the requirements of the standard, because the slopes of the edges in the supply current waveform are finite thanks to which the amplitudes of higher harmonics are reduced. There is also no need to excessively reduce the variable component of the luminous flux. Percent Flicker equal to about 5–10% will satisfy even the rigorous requirements of the future standards referring to lighting installations that are expected to come in force soon (e.g. [6]) and is imperceptible by the human eye. The measured values of Percent Flicker for various sources of light available on the market have been shown in [10].

Finally, we should mention another effect resulting from the proposed method of supplying LED lamps. As the current charging the capacitor is limited by the regulator IA, the lamp will be turned on with some delay. After connecting the supply the capacitor needs a few periods of the line voltage until it becomes charged with a relatively small current IA to the voltage at which the string of LEDs can be turned on. This delay, which is dependent on the capacitance C and the current IA, will never be longer than just a few hundred milliseconds, so it should not be considered by any means as a disadvantage.

The results presented in this contribution are an outcome of statutory activities of the Department of Electronics, Electrical Engineering and Microelectronics

REFERENCES

[1] Standard EN IEC 61000-3-2:2019 Electromagnetic Compatibility (EMC) – Part 3-2: Limits for harmonic current emissions (equipment input current ≤ 16 A per phase)

[2] Li S., Tan S-C., Lee C-K., A Survey, Classification, and Critical Review of Light-Emitting Diode Drivers, IEEE Transactions on Power Electronics, 31 (2016), n.2, 1503-1515

[3] Ning N., Chen W.B., Yu D.J., Feng C.Y., Wang C.B., Selfadaptive load technology for multiple-string LED drivers, Electronics Letters, 49 (2013), n.18, 1170-1171

[4] Kim J., Lee J., Park S., A soft self-commutating method using minimum control circuitry for multiple-string LED drivers, Proceedings IEEE International Solid-State Circuits Conference, San Francisco, USA, 2013

[5] Gao Y., Li L., Mok P.K.T., An AC input switching-converter-free LED driver with low-frequency-flicker reduction, IEEE Journal of Solid-State Circuits, 52 (2017), n.5, 1424-1434

[6] Castro I., Vazquez A., Arias M., Lamar D.G., Hernando M.M., Sebastian J., A review on flicker-free ac-dc LED drivers for single-phase and three-phase ac power grids, IEEE Transactions on Power Electronics, 34 (2019), n.10, 10035-10057

[7] Rymarski Z., The analysis of output voltage distortion minimization in the 3-phase VSI for the nonlinear rectifier ROCO load, Przegląd Elektrotechniczny, 85 (2009), n.4, 127-132

[8] Filus Z., Checinski J., Some remarks on design of LED lamps and their AC direct drivers, Elektronika ir Elektrotechnika, 25 (2019), n.3, 39-42

[9] Standard PN-EN 60038:2012 CENELEC STANDARD VOLTAGES

[10] Chęciński J., Filus Z., Stabilność strumienia światła lamp LED zasilanych z sieci 230 VAC, Przegląd Elektrotechniczny, 94 (2018), nr.8, 5-8

Authors: Jacek Chęciński, PhD, Zdzisław Filus, PhD, DSc, prof. SUT, Silesian University of Technology, Department of Electronics, Electrical Engineering and Microelectronics, ul. Akademicka 16, 44-100 Gliwice E-mails: jacek.checinski@polsl.pl, zdzislaw.filus@polsl.pl

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 97 NR 2/2021. doi:10.15199/48.2021.02.08