Published by 1. Michał KOZIOŁ1, 2. Jarosław ZYGARLICKI1, 3. Dariusz ZMARZŁY1, 4. Elżbieta JANOWSKA-RENKAS2, Politechnika Opolska, Wydział Elektrotechniki, Automatyki i Informatyki (1), Politechnika Opolska, Wydział Budownictwa i Architektury (2)

ORCID: 1. 0000-0001-9075-8656; 2. 0000-0001-9330-4369; 3. 0000-0001-9421-4277; 4. 0000-0002-1877-6216

Abstract. The article presents the problems of measuring electrical parameters on the example of determining the resistivity of concrete samples. In addition, as part of the research work undertaken, a series of experimental measurements were carried out in the system of two electrodes on various samples of geopolymer concrete. The obtained results showed the need to improve the electrodes and subjecting to a detailed analysis of the contact connections between the electrodes and the sample in order to obtain a repeatable method of determining the resistivity of geopolymeric concrete samples.

Streszczenie. W artykule przedstawiono problematykę pomiarów parametrów elektrycznych na przykładzie wyznaczania rezystywności próbek betonowych. Ponadto w ramach podjętych prac badawczych, przeprowadzono serię pomiarów eksperymentalnych w układzie dwóch elektrod na różnych próbkach betonu geopolimerowego. Uzyskane rezultaty wykazały konieczność udoskonalenia elektrod i poddanie szczegółowej analizie połączeń stykowych pomiędzy elektrodami a próbką, celem uzyskania powtarzalnej metody wyznaczania rezystywności próbek betonów geopolimerowych. (Problematyka pomiarów parametrów elektrycznych betonów i geopolimerów)

Keywords: concrete resistivity, resistance measurement, geopolymers.

Słowa kluczowe: rezystywność betonów, pomiar rezystancji, geopolimery

Introduction

The important functional properties of building materials are undoubtedly strength, durability and resistance to various external factors. However, due to the continuous technological progress, the possibilities of creating materials with additional properties, such as the ability to conduct electricity, are also increasing. This opens up new areas for the application of such materials in construction, which may cover both diagnostic and functional aspects. There are already known, for example, cement plastics – mortars and concretes showing electrical properties, which were obtained through the use of electrically conductive additives.

Electrical parameters and, in particular, electrical resistivity are currently used, e.g. to describe the durability and resistance of concrete. In a study [1], the main concrete degradation processes such as chloride ingress and corrosion of reinforcement in concrete were linked to the electrical resistivity of concrete. Two measurement methods are used for this type of analysis, i.e. volumetric and surface resistivity measurements [2-5]. There have also been studies on the relationship between tensile stress and electrical resistivity of carbon fibre reinforced cement matrix [6]. Far fewer literature reports relate to the measurement and analysis of the electrical resistivity of geopolymer composites. In this respect, the authors of the paper [7] analysed, among other things, the electrical resistivity behaviour of fly ash and metakaolin-based geopolymers and showed that the electrical resistivity of the fly ashbased geopolymer is significantly higher than that of the metakaolin-based geopolymers. In addition, there have also been studies on the effect of graphene oxide additive on changing the electrical properties of geopolymers [8].

Nano-additives and nanoparticles are increasingly used, both in building materials [9-10] and in other research areas [11-12], providing a new research and knowledge space that requires continuous improvement and modification of measurement and testing methods.

The technical objective of the research described in this article was to verify the applicability of the two-electrode resistance measurement method on the example of geopolymer concrete samples. On the other hand, the scientific goal of the research subject is to develop a repeatable and reproducible method for determining the resistivity of geopolymeric concrete samples.

Problems of measuring electrical parameters

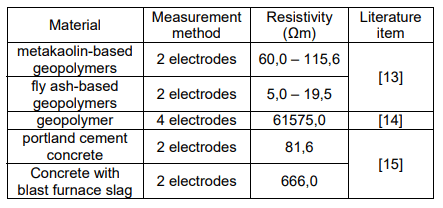

The measurement of the resistance of a concrete sample in a two-electrode system shows some instability. This was observed, for example, on cement samples and cement samples containing recycled metal waste [13], where a stable measurement was obtained after 2 hours. This poses a certain metrological problem that can significantly distort the result obtained and the interpretation of individual parameters. The data available in the literature indicate a variety of approaches to measurement methodology, e.g. by using different sample sizes, measurement frequencies and measurement durations per run. This results in questionable data obtained from such measurements. Example values of the determined resistivity based on the two-electrode system are presented in Table 1.

Table 1. Literature review of selected resistivity values for different concretes

Also, the use of different types of electrodes and their application to the test sample can cause discrepancies in the measured values of its resistance. It is not uncommon for these elements to be described in insufficient detail in publications, which in most cases makes it impossible to verify the reproducibility of the measurements.

Measurement methodology

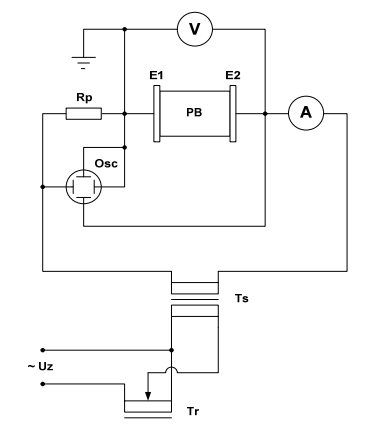

The measuring system (Figures 1 and 2) consisted of a test sample (PB) to which the measuring electrodes (E1) and (E2) were attached. The resistance of the sample was measured using the technical method, while the entire system was supplied with 230V AC (50Hz) via an autotransformer (Tr) and an isolation transformer (Ts).

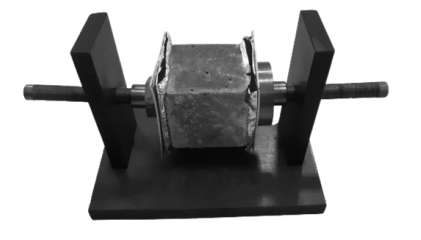

The applied electrodes E1 and E2 consisted of a flexible sponge wrapped with aluminum foil and an additional aluminum plate with dimensions 5.0 cm x 4.5 cm x 0.15 cm (W x H x D) in order to enable stable mounting of the sample with electrodes to the stand (Fig. 3). In order to improve the electrical conductivity of the contact between the electrode and the sample, a conductive gel was additionally applied to the contact point before each measurement. ECG and USG gel, which has a neutral pH (6.7 – 7.3), was used for the tests. Dedicated electrodes were made for each sample. The tests were carried out on 5 samples of geopolymer concrete (GP1-GP5) with identical dimensions 5.0 cm x 4.5 cm x 5.0 cm (width, height, length) and different composition.

A 2-electrode system and an alternating voltage (AC) with a value of 10.5 V were used. The voltage value was selected experimentally on the basis of the repeatability of the measurement series for individual samples. The measurement consisted of registering the current flowing through the sample, which was measured using a milliammeter and oscilloscope.

The tests were carried out after 60 days of maturation of the samples, which had an average moisture content of 24%. The moisture content was measured using a universal moisture meter with solid-state sensors. All samples were stored under the same environmental conditions (air temperature 20o , humidity 50-55%) The correlation of the moisture content of the samples with electrical resistivity was not analysed at this stage of the study.

Two measurement methods were used to provide additional verification of the measured current intensity and to eliminate possible random errors. Measurements for all samples were made under identical environmental conditions, i.e.: air temperature 20o , humidity 56%. Due to the experimental nature of the study, focused on the measurement problem, the influence of the sample’s own moisture content and environmental changes were not analyzed.

Based on the measured resistance and geometrical parameters of the electrodes, the resistivity of all samples was determined according to the following formula:

where: R – resistance (Ω), A – electrode surface (m2), l – distance between the electrodes (m) The electrical resistivity was determined as a representative value for each sample as the average value of 5 measurements in one series. Results and discussion As part of the research, 5 measurement series were carried out for 5 consecutive days, during which the resistance was measured at fixed time intervals, which were selected experimentally based on the recorded values. During the tests, the electrical resistance for the test samples was found to stabilise after approximately 10 minutes. Therefore, for comparison purposes, the electrical resistance for all samples was analysed over a 10-minute cycle. The determined value of resistivity was also compared before and after applying the conductive gel. The example results for sample GP5 are as follows:

– without gel: ρ = 5,92 (Ωm),

– with gel: ρ = 3,78 (Ωm)

The difference in comparison to the measurement without the gel was obtained at the level of 36%, which is a significant value and indicates a large impact on the obtained results. Results presented in this paper refer to measurements in a 2-electrode system with the use of a conductive gel.

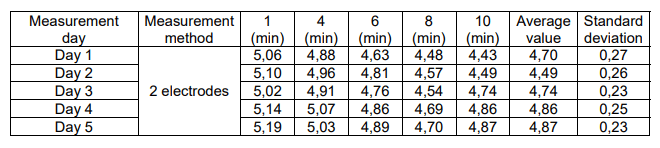

Example results of the resistivity determined from the measurements for sample GP1 are presented in Table 2.

Table 2. Determined resistivity for sample GP1

The obtained partial values of electrical resistivity are characterized by a low dispersion for all tested samples, and similar values obtained on consecutive measuring days.

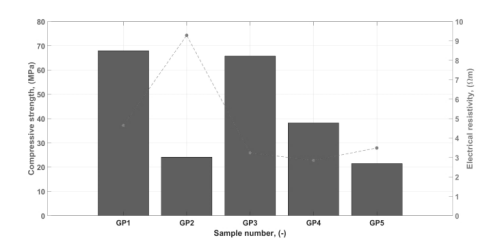

The averaged values of resistivity, determined for the measurements made on day 1, for samples GP1-GP5 are presented in Fig. 4.

The research work presented in this article is mainly concerned with the issue of measuring the electrical parameters of concrete samples, therefore the influence of sample components on the recorded values and the clamping force of the sample was not analyzed. The clamping force applied during the test was sufficient and reproducible for the adopted scope of the tests. Detailed analysis of the clamping force of the sample requires separate and dedicated tests.

Comparing the obtained resistivity values for measurements made with a milliammeter and an oscilloscope, it can be assumed that the measurement system used was chosen correctly. An example comparison of the average values of the determined resistivity based on measurements obtained from both methods is shown in Figure 5.

For comparison purposes, the obtained strength and resistivity parameters of the tested samples were compared (Fig. 6). It should be noted that this comparison is only illustrative, as no studies have been conducted in this area. Such correlation requires multi-variant tests and analyzes as well as a repeatable and reproducible method of measuring the resistance of the sample.

Conclusions

Based on the research carried out, the following conclusions can be drawn:

– for measurements in the 2-electrode system, the ASTM C1760 standard [16] was dedicated (which was withdrawn in 2021) and is no longer widely used, therefore the research teams set up their own configuration of the test stand. A certain standardization of concrete samples dedicated to the measurement of electrical parameters is necessary, which will enable the development of a methodology for repeatable and stable resistance measurements with a standardized voltage,

– it is also necessary to analyze the effect of the pressure of the electrodes on the test sample in terms of repeatability and reproducibility of the measurements,

– further research is recommended to obtain durable and reusable electrodes, characterized by a very low inherent resistance, adequate flexibility, enabling precise adhesion to the tested sample. In the further stage of the research, the authors assume the construction of such electrodes based on platinum electrodes and conductive rubber, and the establishment of a repeatable and reproducible test scenario that could be used for experimental concretes with various nanoadditives,

– research also requires the correlation of AC and DC resistance measurements. The type of current used may affect the accuracy of the measurement result

– the test program should also take into account the maturation time of the sample, during which the resistance may change due to the precipitation of moisture from the material. Research should be conducted to verify this correlation,

– an important aspect also seems to be testing in various environmental conditions that would simulate the actual working conditions of e.g. structural elements,

– an interesting direction of research seems to be the analysis of changes in the resistance of a concrete sample during strength tests. However, this requires the development of a separate measurement methodology

REFERENCES

[1] Saleem M., Shameem M., Hussain S.E., et al., Effect of moisture, chloride and sulphate contamination on the electrical resistivity of Portland cement concrete, Constr. Build. Mater. 10 (3) 209–214, 1996

[2] Oleiwi, H.; Wang, Y.; Xiang, N.; Augusthus-Nelson, L.; Chen, X.; Shabalin, I. An experimental study of concrete resistivity and the effects of electrode configuration and current frequency on measurement. In Proceedings of the 6th International Conference on Durability of Concrete Structures, ICDCS 2018

[3] Cosoli, G.; Mobili, A.; Tittarelli, F.; Revel, G.M.; Chiariotti, P. Electrical Resistivity and Electrical Impedance Measurement in Mortar and Concrete Elements: A Systematic Review. Appl. Sci. 2020, 10, 9152

[4] Azarsa P, Gupta R. Electrical Resistivity of Concrete for Durability Evaluation: A Review. Adv Mater Sci Eng 2017;2017:1–30

[5] Payakaniti P, Pinitsoontorn S, Thongbai P, Amornkitbamrung V, Chindaprasirt P. Electrical conductivity and compressive strength of carbon fiber reinforced fly ash geopolymeric composites. Constr Build Mater 2017;135:164–76

[6] Teomete, E. Crack length and tensile strain correlation with electrical resistance of carbon fiber reinforced cement matrix9composites measured by three-point bending test and splitting tensile test. Cem. Wapno, Bet. 2017, 1

[7] Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 1–9

[8] Krystek, M.; Dawczyński, S.; Górski, M.; Stepien, M. Experimental investigation on mechanical and electrical properties of GO-geopolymer composite. In Proceedings of the NICOM6 – Sixth International Symposium on Nanotechnology in ConstructionAt: Hong Kong; 2018

[9] Janowska-Renkas, E., & Kaliciak, A. (2020). Properties of geopolymers from conventional fly ash activated at increased temperature with sodium hydroxide containing glass powder obtained from the recycling of waste glass. MATEC Web of Conferences, 322, 1–14

[10] Norambuena-Contreras J, Quilodran J, Gonzalez-Torre I, Chavez M, Borinaga-Treviño R. Electrical and thermal characterisation of cement-based mortars containing recycled metallic waste. J Clean Prod 2018;190:737–51

[11] Nagi Ł, Płużek A. Electrical Strength of Natural Esters Doped by Iron Nanopowder in a Hydrophobic Carbon Shell. Materials. 2020;13(8):1–12.

[12] Kalus W, Zygarlicki J, Nagi Ł, Kozioł M. Application of nanocarbon structures to optimize the design parameters of conductive surfaces of electroadhesive pads. In 2021 6th International Conference on Nanotechnology for Instrumentation and Measurement (NanofIM). 2021. p. 1–4

[13] Jingming Cai, Jinlong Pan, Xiaopeng Li, Jiawei Tan, Jiabin Li, Electrical resistivity of fly ash and metakaolin based geopolymers, Construction and Building Materials, Volume 234, 2020, 117868,

[14] Zainal, Farah Farhana, et al. “The Electrical Resistivity of Geopolymer Paste by Using Wenner Four Probe Method.” Key Engineering Materials, vol. 660, Trans Tech Publications, Ltd., Aug. 2015, pp. 28–33

[15] McCarter, WJ, Taha, HM, Suryanto, B & Starrs, G 2015, ‘Twopoint concrete resistivity measurements: interfacial phenomena at the electrode–concrete contact zone’, Measurement Science and Technology, vol. 26, no. 8, 085007

[16] ASTM C1760—12 Standard Test Method for Bulk Electrical Conductivity of Hardened Concrete.

Authors: dr inż. Michał Kozioł, Politechnika Opolska, Katedra Elektroenergetyki i Energii Odnawialnej, ul. Prószkowska 76, 45- 758 Opole, E-mail: m.koziol@po.edu.pl; dr hab. inż. Jarosław Zygarlicki, Politechnika Opolska, Katedra Elektroenergetyki i Energii Odnawialnej, ul. Prószkowska 76, 45-758 Opole, E-mail: j.zygarlicki@po.edu.pl; prof. dr hab. inż. Dariusz Zmarzły, Politechnika Opolska, Katedra Elektroenergetyki i Energii Odnawialnej, ul. Prószkowska 76, 45-758 Opole, E-mail: d.zmarzly@po.edu.pl; dr hab. inż. Elżbieta Janowska-Renkas, Politechnika Opolska, Katedra Inżynierii Materiałów Budowlanych, E-mail: e.janowska-renkas@po.edu.pl.

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 98 NR 10/2022. doi:10.15199/48.2022.10.52