Published by Piotr PAJĄK1, Bartłomiej SZAFRANIAK1, Anna DĄDA2, AGH University of Science and Technology, Faculty of Electrical Engineering, Automatics, Computer Science and Biomedical Engineering (1), MGGP S.A., Krakow Branch (2)

Abstract. Low voltage surge arresters work in a very different environmental conditions. During the exploitation, under the influence of environmental exposures, the structure of metal oxide surge arresters (MOSA) is gradually degraded. These processes can change their protective properties and lead to a reduction in the effectiveness of surge protection. The aim of the paper is to analyze the influence of environmental exposures on the electrical parameters of low voltage surge arresters.

Streszczenie. Warunki środowiskowe w jakich pracują niskonapięciowe ograniczniki przepięć są bardzo zróżnicowane. Podczas eksploatacji, pod wpływem narażeń środowiskowych, struktura ograniczników przepięć ulega stopniowej degradacji. Procesy te mogą powodować zmiany parametrów elektrycznych ograniczników i prowadzić do zmniejszenia skuteczności ochrony przeciwprzepięciowej. Celem referatu jest analiza wpływu narażeń środowiskowych na parametry elektryczne niskonapięciowych ograniczników przepięć. Analiza wpływu narażeń środowiskowych na parametry elektryczne niskonapięciowych ograniczników przepięć

Keywords: metal oxide surge arresters, impedance spectroscopy, water immersion, leakage current.

Słowa kluczowe: beziskiernikowe ograniczniki przepięć, spektroskopia impedancyjna, degradacja pod wpływem wilgoci, prąd upływowy

Introduction

The main purpose of using surge arresters is to protect the insulation of devices from significant voltage increases that may occur in the power system. Reliable operation of the surge arresters and preservation of reduced voltage values declared by manufacturers within a long time is required in order for this protection to be effective. Surge arresters are exposed to many environmental factors during their exploitation, which directly affect the operating parameters, advance their ageing and in extreme cases may damage them. Current stroke, high temperature, moisture penetration and salt contamination are these negative impact factors. Substantial penetration of moisture in combination with high air pollution, significantly advance the degradation of surge arresters, decreasing the protective voltages of the varistor and with an avalanche way increase in leakage current, they can even lead to its damage [1].

The basic element of sparkless surge arresters are varistors made of zinc oxide (ZnO) with additions of other metal oxides, Bi2O3, CoO, MnO, Sb2O3 among others. The varistors are resistors whose resistance depends on the voltage applied to them. The material from which the varistors are made is properly prepared – first ground and homogenized, and then pressed and sintered at high temperatures. The end result of such a technological process is a polycrystalline structure with unique properties. The basic element of the varistor’s microstructure is grain, which should be characterized by appropriate size, homogeneity and low resistivity. The formation of grain microstructure, occurring at the stage of production processes, determines the creation of current paths in the varistor. The current flowing through the varistor is the sum of partial currents flowing through its structure through various paths. Paths with fewer borders are led by larger currents. Voltage drops in a given varistor sector depend on the number of intergranular borders, which is directly influenced by the amount and size of grains. The total voltage drop on the varistor results from the equalization of voltages by varying the leakage currents [2].

The chemical composition and suitably selected parameters of the varistor manufacturing process allow for the shaping of their strongly nonlinear current-voltage characteristics (U = C · Iβ; V – voltage, I – current, C – constant, β – nonlinearity coefficient) [3, 4].

The mechanism of current conduction on the varistor is related to phenomena occurring at the boundaries between grains. At the interface of neighboring grains there are potential barriers resulting from the electric charge accumulated on the boundary surfaces. In the characteristics of the dependence of the electric field intensity on the value of varistor current density E = f (J), three clearly distinct ranges can be distinguished (Fig. 1): pre-breakdown range (normal operation range), breakdown range (stabilization range) and saturation range [5].

Varistors are usually made in the form of cylindrical disks of various diameters and thicknesses. They are closed in sealed enclosures designed to protect against external factors, in particular against moisture (Fig. 2a, 2b). The geometrical dimensions of the varistor are related to the assumed value of the discharge current (diameter, surface area of the disk), the operating voltage (thickness of the disk) and its ability to absorb energy (disk volume) [6]. Typically, the ZnO grain diameter is a few micrometers (Fig. 2c).

Diagnostic tests of surge arresters are carried out at all stages of their technical life. They are based on various evaluation methods, for example on visual inspection, thermovision studies, or on the measurement of electrical parameters, performed at both constant and alternating voltages. The energy (overvoltage) and environmental (physicochemical) exposures occurring in operation lead to changes in the internal structure and various types of damage to the arresters [6].

Research Program

This work contains tests and analysis of the results performed on a series of low voltage surge arresters with similar parameters produced by two different manufacturers. Four samples were selected for observing the parameters of the tested arresters, two samples of object A and two samples of object B. The analysis of the results is to determine the permissible dispersion in which the monitored parameters may be contained. The tests were performed on surge arresters designed for installation in low voltage aerial power transmission networks. Their technical parameters are listed in table 1.

Table 1. Selected parameters of tested SPD

All presented measurements were made in High Voltage Laboratory of Electrical and Power Engineering Department of AGH University of Science and Technology in Krakow, Poland. Surge arresters were tested with the following procedure:

Impedance spectroscopy

The impedance spectroscopy method was used to observe changes in the dielectric properties of the tested surge arresters. This is a test method used to determine the physical and chemical properties of materials and electrochemical processes. It consists in measuring the linear, electrical response of the tested object as a result of stimulation with a small electromagnetic signal in a wide frequency band. Small voltage induction allows treating the tested element, in this case the surge arrester as a linear element. The measuring instrument depending on the impedance frequency Z(ω) is the frequency response analyzer (FRA). This device generates a stimulation of a specific shape and selects individual points on the frequency scale. An impedance spectrum is created from the measured current responses at selected frequencies. The current flowing through the tested object is combined with two synchronous, orthogonal reference signals (cosωt and sinωt), one of which corresponds to an trigger signal.

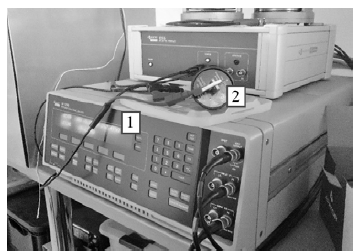

The characteristics of the relative permittivity εr and the dielectric loss coefficient tgδ were registered depending on the frequency f for all samples, in no way previously operated or subjected to laboratory exposures. The measurements were carried out over a wide range of frequencies, from 10-2 Hz to 104 Hz. The measuring station was equipped with a Solartron 1260A frequency response analyzer, Solartron 1296A dielectric interface and a supervising computer (Fig. 3).

Electrometer – recording of the leakage current waveform

In order to performed detailed diagnostic, it is particularly important to analyze the pre-breakdown range of surge arresters, because this is the state of their normal operation. Then, a leakage current flows through the arrester. Measurement of this current enables the technical condition of arrester to be evaluated. Observation of the value and shape of the leakage current is often used to assess the operation of surge arresters [7-10].

The tested surge arresters were connected in such a way that the measurement only includes the cross-current component of the leakage current. The surface current was shielded – the arresters were placed in a copper band which was grounded.

The leakage currents waveforms were recorded over time, all samples were subjected to the experiment. The measurement took place for one minute at constant voltage 308V, which is the highest value of the operating voltage. The measurements were carried out using an electrometer from the B2987A series of Keysight Technologies.

Exposure to moisture and salt solutions

Surge arresters were combined into two pairs. Each pair is a object A surge arrester and a object B surge arrester. In order to imitate the actual environmental conditions to which devices are subjected during exploitation, each pair of arresters has been drenched in the following liquids: water and 5% NaCl solution. Ageing was executed at an ambient temperature of 23°C to 25°C and lasted 600h. Each time, after another 150 hours of ageing, before the next tests, the surge arresters were dried.

Results and Analysis of Measurements

The article presents the results of testing low voltage surge arresters. Tests were performed using the impedance spectroscopy method. This is one of the nondestructive testing methods that can be used for diagnostic of ZnO varistors. The obtained test results are presented in the following figures (Fig.4 – Fig.7).

The analysis of impact of ageing based on the εr and tgδ wideband characteristics shows gradual growth of these parameters’ values. That effect has been observed within the range of low frequencies for all surge arresters. It was also found that the reaction of surge arresters within the same voltage group, immersed in a 5% NaCl solution, is different. Strong growth of object A surge arresters’ tgδ can be observed at the frequency range of kHz’s whereas this parameter does not change for object B surge arresters at the same range of frequency.

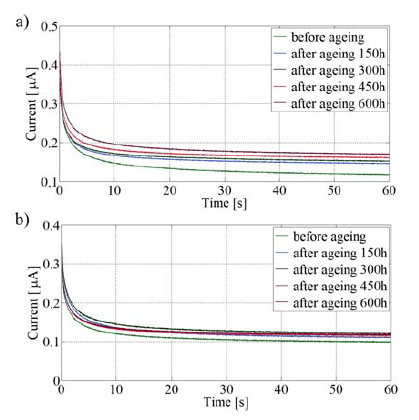

Tested surge arresters have reached similar values of leakage currents. That value is influenced by the relatively short ageing time and lack of raised temperature. Nevertheless, the moisture penetration into arresters’ interior increases the leakage current. In the example of object A, it can be observed that the leakage current values grow with time, and the differences between respective waveforms are greater while immersed in a 5% NaCl solution. In the case of object B, these differences are not so significant.

The voltage–current characteristics of metal oxide varistors depend on moisture content at low current, in the vicinity of continuous operating voltage [11]. Greater leakage current of surge arresters immersed in 5% NaCl solution in relation to immersion in water was observed. The changes are more significant for the arresters manufactured by object A than object B, which means that they are much more sensitive to moisture impact. The use of this type of arresters in environments with significant contamination and salinity may cause major difficulties in maintaining the stability of the requested parameters.

Summary and Conclusions

Based on the results, moisture penetration into arresters interior is confirmed. The impact of immersion in water and in a 5% NaCl solution on the surge arresters’ parameters was already noticeable, despite the relatively short ageing period. It points out that a deterioration of their technical condition ensued.

There are visible changes in the shape of wideband characteristics as a result of the surge arresters’ ageing test. Within the range of low frequencies, the εr and tgδ characteristics reach the higher values along with the length of ageing time, as well as for immersion in water and in 5% NaCl solution. Tgδ(f) characteristics indicate an significant increase in the conductivity losses at low frequencies.

The impact of moisture penetration into varistors’ interior is also visible on obtained leakage currents waveforms. Surge arresters aged in 5% NaCl solution show higher values of leakage current compared to an analogous test in water. The values of these currents are different for various series of arresters used within the same voltage group. Analysis of appearances occurring during the ageing processes is an additional source of information on the mechanism of current conduction in the varistor.

REFERENCES

[1] Wanderley Neto E. T., Da Costa E. G., Ferreira T. V., Maia M. J. A., Failure Analysis in ZnO Arresters Using Thermal Images, IEEE PES Transmission and Distribution Conference and Exposition Latin America, Venezuela, (2006)

[2] Mielcarek W., Uwarunkowania technologiczne warystorów tlenkowych, Prace Instytutu Elektrotechniki, Zeszyt nr 212, Warszawa, (2002)

[3] Chrzan K. L., High-Voltage Surge Arresters, Wrocław, Dolnośląskie Wydawnictwo Edukacyjne publishing company, (2003)

[4] Flisowski Z., High Voltage Technology, Warszawa, PWN publishing company, (2017), 226–234

[5] Florkowska B., Furgał J., Zydroń P., Materials Engineering in Electrical Engineering. Laboratory, AGH issues, Kraków, (2012), 72–80

[6] Bonk M., Fusnik Ł., Szafraniak B., Zydron P., Influence of temperature and high-energy stresses on selected wideband characteristics of metal-oxide varistor parameters, Proc. 9th Int. Sci. Symp. Electr. Power Eng. Elektroenergetika 2017, (2017), 306–310

[7] Biglar B., Jayaram S., Cherney E. A., Evaluation of the insulation design of polymer housed surge arresters using saltfog test, 2000 Conference on Electrical Insulation and Dielectric Phenomena, (2000), 385–388

[8] Da Silva D. A., Costa E. C. M., Pissolato J., De Jesus R. C., De Franco J. L., De Abreu S. R., Romano M. A. A., Lahti K., Evaluation of the moisture ingress and the electrical performance on polymeric surge arresters of distribution networks, 18th International Symposium on High Voltage Engineering, (2013), 349–354

[9] Silva D. A., Costa C. M., Franco J. L., Abreu S. R., Jesus R. C., Antonionni M. , Pissolato J., Polymer Surge Arresters: Degradation Versus Electrical Performance, (2012)

[10] Dalai S., Chatterjee B., Study on the effect of moisture ingression into metal oxide surge arrester using leakage current analysis, 3rd International Conference on Condition Asstessment Techniques in Electrical Systems (CATCON), (2017), 330–334

[11] Chrzan K. L., Influence of moisture and partial discharges on the degradation of high-voltage surge arresters, European Transactions on Electrical Power, Euro. Trans. Electr. Power 2004, (2004), No. 14, 175-184

Authors: dr inż. Piotr Pająk, AGH University of Science and Technology, al. Mickiewicza 30, 30-059 Kraków, Poland, E-mail: ppajak@agh.edu.pl, mgr inż. Bartłomiej Szafraniak, AGH University of Science and Technology, al. Mickiewicza 30, 30-059 Kraków, Poland, E-mail: szafrani@agh.edu.pl, mgr inż. Anna Dąda, MGGP S.A., Cracow Branch, e-mail: annadada0709@gmail.com

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 96 NR 1/2020. doi:10.15199/48.2020.01.14