Published by Krystian Leonard CHRZAN1, Maciej ZIPP2,

Wrocław University of Science and Technology (1), Gates Corporation (2)

Abstract. Leakage currents on silicone and porcelain housings were measured at a 110 kV substation (site pollution severity class heavy) for 7 months. Both types of housing had a similar geometry. The current on porcelain housings is usually up to 4,7 times higher than on silicone housings. However, significantly smaller currents (up to 2,6 times) were recorded on the porcelain insulators over a period of 8 days. Similar rare behavior was earlier seen at Glogow pollution test station and at Koeberg pollution test station on porcelain and silicone insulators with the same profiles. A better washability of porcelain during stronger rains plays a very important role in this phenomenon. It was shown that small leakage currents, usually in the range 4 -10 mA, cause surface erosion of silicone rubber housings.

Streszczenie. Przez 7 miesięcy mierzono prąd upływu na osłonach silikonowych I porcelanowych na rozdzielni 110 kV znajdującej się w III strefie zabrudzeniowej). Osłony miały podobny kształt. Prąd na osłonie porcelanowej był zazwyczaj większy niż na osłonie silikonowej (do 4,7 razy). Jednakże w ciągu 8 dni prąd na osłonie porcelanowej był mniejszy (do 2, 6 razy). Podobne takie rzadkie przypadki zauważono wcześniej na stacjach zabrudzeniowych w Koeberg i w Hucie Głogów na izolatorach o identycznym kształcie. Bardzo ważną rolę w tym zjawisku odgrywa lepsze oczyszczanie porcelany przez silniejsze deszcze. Wykazano, że niewielkie prądy upływu rzędu 4 –10 mA powodują erozję powierzchniową osłon silikonowych. (Nietypowe prądy upływu na osłonach silikonowych).

Keywords: Flashover, Surface contamination, surface discharges.

Słowa kluczowe: Przeskok, zanieczyszczenie powierzchni, wyładowania powierzchniowe.

Introduction

The flashover voltage of silicone rubber insulators is higher than the flashover voltage of porcelain insulators under the same contamination conditions. And similarly, the leakage current on contaminated and hydrophobic silicone insulators is smaller than the leakage current on hydrophilic porcelain insulators. A lot of research in laboratories and in the field confirms the excellent properties of silicone insulators [1]. The best comparison could be demonstrated after rapid wetting of both insulators. When both insulators are uniformly sprayed, and after switching the voltage, the current on a porcelain insulator is many times higher (e.g. 100 times) than on a silicone insulator [2]. However, under natural conditions and under continuous operating voltage, the currents on porcelain insulators are only up to a few times higher than the currents on silicone insulators [3]. Wallce Vosloo [4, 5] and Krystian L. Chrzan [2] showed that the currents on porcelain insulators are sometimes 10% – 20% higher than on porcelain insulators with identical profiles. In this paper we show that the ratio of currents on porcelain insulators to the currents on silicone insulators changes in the range of 0,38 – 4,7 over the course of one day.

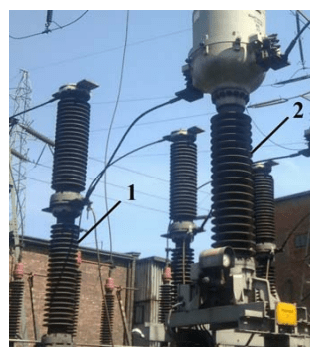

The direct impulse to measure the leakage current on silicone housing was surface erosion found two years after the installation of combined voltage/current transformers at a 110 kV substation located in a heavily contaminated industrial environment with daily dust precipitation of 2 g/m2 (Figure 1). The aim of the leakage current measurements was to determine the level of current causing silicone rubber erosion.

Current measurements and test objects The current measurements were carried out with a 4 channel digital recorder manufactured by KORIN Company. The sampling rate was 5 kHz, the sampling resolution was 10 bits and the measuring range was 1 – 400 mA (with 250 Ω current shunt). The data was stored in 2 GB memory. Thanks to a special algorithm, the memory enabled a very long collecting data period of 8 years. The current peak was only storied in the memory when its value was higher than the previous value. The installation of the measuring system at the substation is shown in Figure 2.

1 – Insulator, 2 – Current collection ring, 3 – Housing, 4 – Surge arrester, 5 – Current shunt (resistance), 6 – Data acquisition system

Table 1. Dimensions of research objects

The currents were measured on a 110 kV porcelain housing of EDF SV 2-1 switchgear and on two silicone housings of SVAS 123/OG combined voltage/current transformers (Figure 3). The leakage distance of the porcelain housing amounted to 328 cm, and that of the silicone housing to 288 cm. Moreover, the other dimensions of both housings are similar (Table 1).

Results

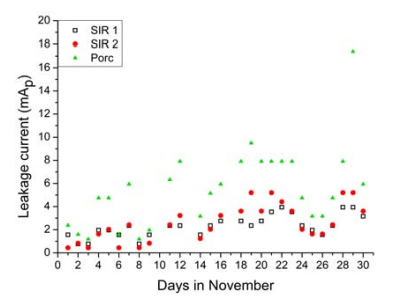

The currents measured in November on the porcelain housing were considerably higher for 22 days than those on the silicone housing (Figure 4). The currents on both silicone housings were sometimes equal, but sometimes small differences were observed. The maximum amplitude of 17,4 mA was noted on the porcelain housing on November, 29. On the same day, the current on the silicone housing reached the value of 4 mA (Table 2). The maximum ratio of 4,7 of current on the porcelain to the current on the silicone rubber was noted on March, 24.

Table 2. Maximum ratio of currents on the porcelain housing to currents on the silicone rubber housing

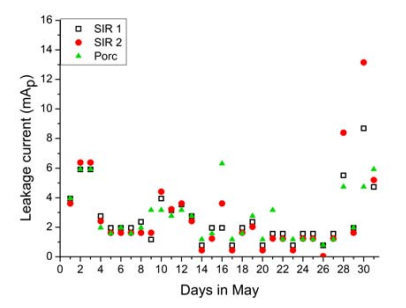

In January and in the following months a strange phenomenon was detected. The currents on the porcelain insulators on some days were considerably smaller than the currents on the silicone insulators. The eight cases from the period January – May are listed in Table 3. The observed anomalous differences between the current peaks on the porcelain and silicone rubber were larger this time than when previously published [2, 5]. On May, 28 and on May, 30, the current on the silicone housing was higher than on the porcelain housing (Figure 5).

Table 3. Anomalous relation of currents on the porcelain insulators to currents on the silicone rubbers insulators

Correction due to different insulator profiles

The silicone housings and porcelain housing have not identical profiles. Their form factors are 3,2 and 4,5 respectively (table 1). Assuming a uniform hydrophilic pollution layer and the same surface conductivity on silicone an porcelain housings, we get the following leakage current ratio:

Under such (unrealistic) conditions the current on porcelain housing would be smaller than the current flowing on the silicone housing.

If the porcelain housing were in the shape of the silicone housing, then its leakage current would be greater 4,5/3,2=1,41 times. These corrected current values on the porcelain housing and corrected current ratios from table 3 are compiled in the table 4.

Table 4. Anomalous relation of currents on the porcelain insulators to currents on the silicone rubbers insulators after correction

Despite the correction, the leakage currents on the porcelain housing are still smaller than the currents on silicone housing.

Discussion

Hydrophilic contamination on the porcelain surface absorbed water and formed a continuous layer after wetting. Conversely, water droplets on the hydrophobic polluted silicone rubber were separated from each other. Therefore, the surface resistance was high and the current was small. These very different scenarios explain why current on a hydrophilic surface is many times greater than on a hydrophobic surface after a so-called “cold switch on”.

However, under field conditions the insulators had been under the operating voltage for many weeks. There were dry bands on the hydrophilic surface that had a high resistance. Therefore, the ratio of the current on the porcelain to the current on the silicone rubber was not so high. Cleaning of the insulator due to rain also plays a very important role. The contamination from porcelain insulators is easy to remove, but not so easy from the silicone rubber. There was more contamination on the silicone rubber than on the porcelain [6]. The importance of the insulator cleaning by strong rain can be shown in May. On May, 3, 10 and 12, rain with daily precipitations of 28, 9 and 9 mm occurred and the currents on the porcelain insulator were similar to the currents on the silicone insulator. During two periods of rain at the end of May the currents on the porcelain insulator were smaller than on the silicone insulator (Figure 6).

The distribution of contamination is also important. It was very uneven on the porcelain insulators [7], and less uneven on the silicone insulators [8]. The equivalent salt deposit density ESDD on silicone insulators can be 2-3 times greater than on porcelain insulators [2,6], but locally much greater differences were found. The ESDD on the upper side of the top shed of the porcelain post insulator was 15 times greater than on the porcelain post with bare glazes [7].

Conclusions

Anomalous currents on silicone insulators were found at an industrial site with heavy pollution. A similar phenomenon was earlier found under heavy sea salt pollution (Koeberg pollution station) and under light industrial pollution (Glogow test station). Over the course of 7 months, currents on the porcelain housing were for 8 days considerably smaller than currents on the silicone housing. A better washability of the porcelain housing during stronger rains plays a very important role in this phenomenon. 10 mA leakage currents have caused apparent surface erosion of silicone rubber.

The authors gratefully acknowledge S. Maguda, from KORINE Company, and also L. Sieczko and D. Paluch from the Legnica Copper Smelting Plant for their help in organizing the current measurements.

REFERENCES

[1] Amin M., Amin S., Ali S., Monitoring of leakage currents for composite insulators and electrical devices”. Reviews on Advanced Materials Science, vol. 21, (2009) pp. 75-89

[2] Chrzan K.L., Leakage currents on naturally contaminated porcelain and silicone insulators,” IEEE Trans. on Power Delivery, vol. 25, (2009) no. 2, pp. 904–910

[3] Homma H., Kuroyagi T., Ishino R., Takaashi T., Comparison of leakage current properties between polymeric insulators and porcelain insulators under salt contamination conditions,” Int. Symposium on Electrical Insulating Materials, Kitakyushu, Japan, (2005), paper P1-14

[4] Vosloo W.L., A comparison of the performance of high voltage insulator materials in a severely polluted coastal environment”. Ph.D. thesis, University of Stellenbosch, South Africa, 2002

[5] Chrzan, K.L., Vosloo W.L., Holtzhausen J.P., “Leakage currents on porcelain and silicone insulators under sea or light industrial pollution.” IEEE Trans. on Power Delivery, vol. 26, (2011), no. 3, pp. 2051–2052

[6] Zhang H.Ye, Ji Y.M., Sun W.Y., Kondo K., Imakoma T., Contamination accumulation and withstand voltage characteristics of various types of insulators. 7th Int. Conference on Properties and Applications of Dielectric Materials, Nagoya, Japan, (2003), pp.1019-1023

[7] Chrzan K.L., Pollution accumulation on silicone insulators and on porcelain insulators. (in Polish) Przegląd Elektrotechniczny, (2011), vol. 87, no. 12a, pp. 129-132

[8] Gubanski S.M., Wankowicz J.G., Distribution of natural pollution surface layers on silicone rubber insulators and their UV absorption.” IEEE Trans. on Electrical Insulation, vol. 24, (1989), no. 4, pp. 689–697

Authors: dr hab. inż. Krystian Leonard Chrzan, Politechnika Wrocławska, Wydział Elektryczny W5, Katedra K38, ul. Wybrzeże Wyspiańskiego 27, Wrocław, E-mail: krystian.chrzan@pwr.edu.pl; mgr inż. Maciej Zipp, studied at the Wroclaw University of Science and Technology, Faculty of Electrical Engineering, He is now with the Gates Corporation, 59-220 Legnica, Poland, e-mail: m.zipp@10g.pl

Source & Publisher Item Identifier: PRZEGLĄD ELEKTROTECHNICZNY, ISSN 0033-2097, R. 96 NR 10/2020. doi:10.15199/48.2020.10.15